Concrete protection pile

A protective pile and concrete technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as poor slope protection effect of concrete protective walls, landslides, dam breaks, and easy deviation of protective piles, so as to avoid soil erosion , Good bending resistance, good slope protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

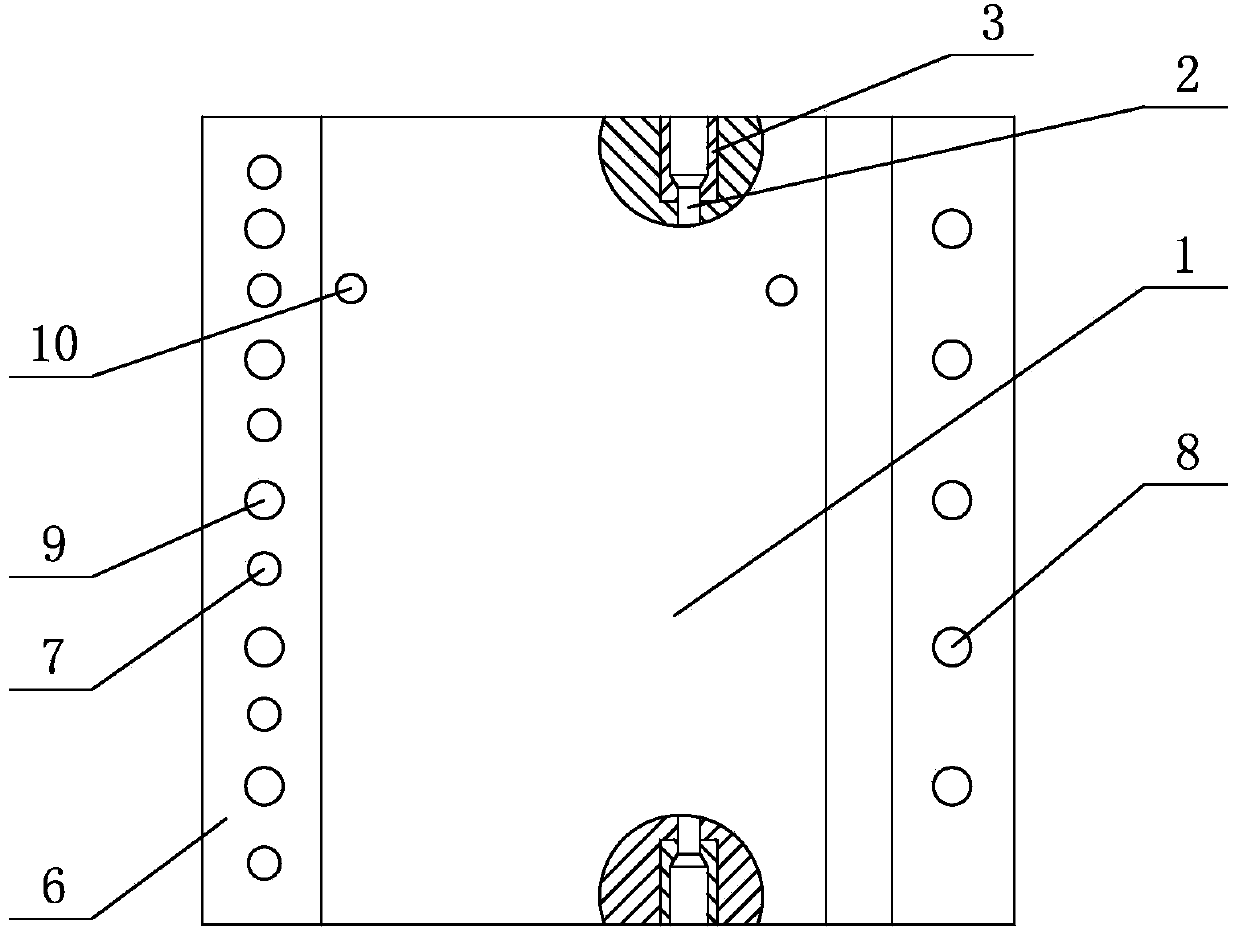

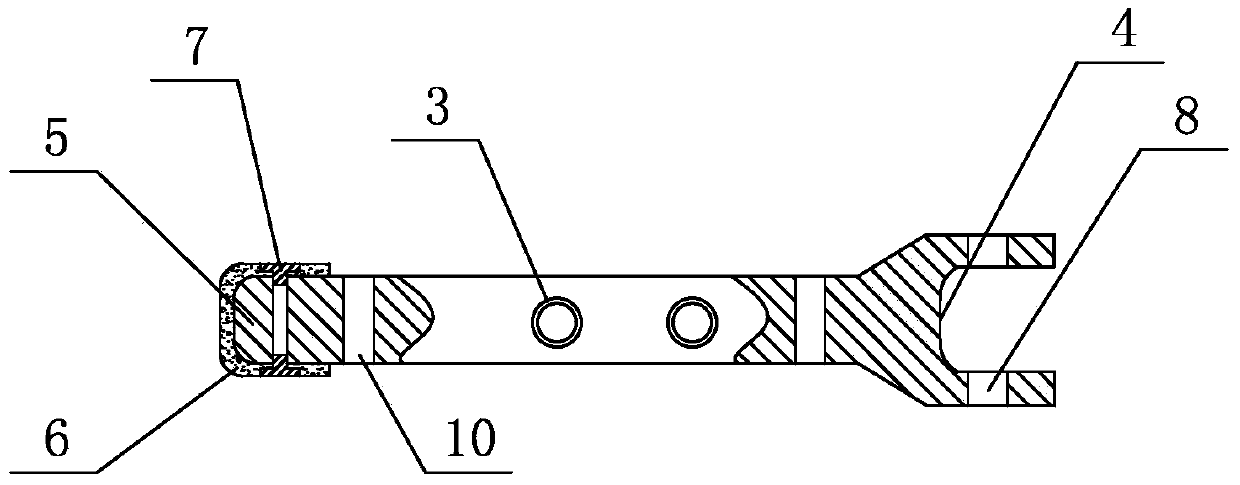

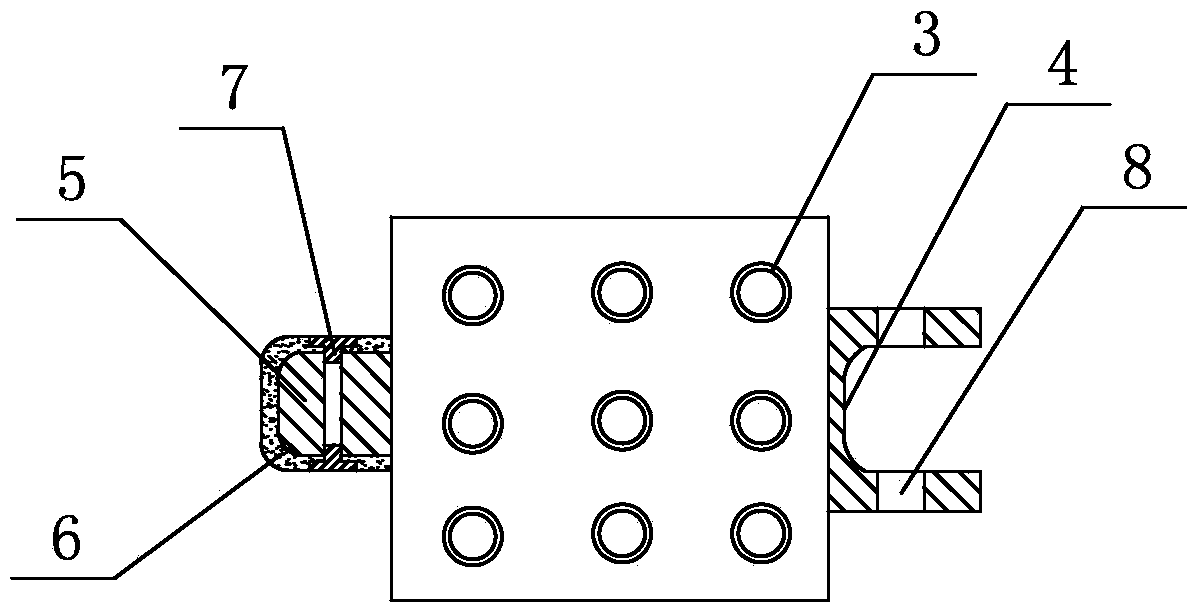

[0014] Such as Figure 1-3 Shown: a concrete protective pile, inside the pile body 1, several prestressed steel rods 2 are arranged along the vertical direction of the pile body 1, steel wire mesh is arranged on the prestressed steel rods 2, and the prestressed steel rods 2 Rebar anchor nuts 3 are respectively provided at both ends of the pile body 1, a U-shaped socket 4 is provided at one end of the pile body 1, a plug-in 5 matching with the U-shaped socket 4 is provided at the other end of the pile body 1, a flexible rubber sleeve 6 is covered and fixed on the plug-in 5 through the countersunk crab shell bolt 7, and several first bolt holes 8 are arranged symmetrically along the vertical direction on the two straight ends of the U-shaped socket 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com