Gravity type offshore wind power foundation capable of towing in self-floating mode and construction method thereof

A technology of offshore wind power and self-floating towage, which is applied to infrastructure engineering, wind power generation, ships, etc., can solve the problems of increasing the amount of foundation construction, increasing the cost of foundation construction, and the weight of the structure itself, so as to reduce the construction engineering Quantity, innovative infrastructure, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

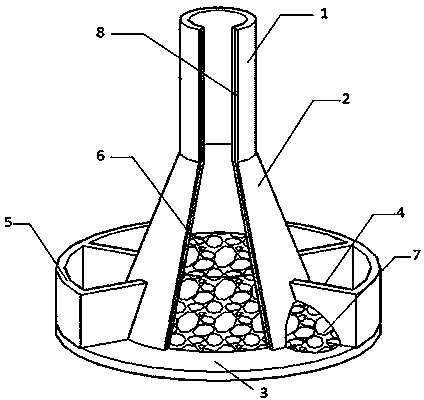

[0023] A self-floating towable gravity offshore wind power foundation, such as Figure 1-Figure 3 As shown, it is composed of connection section 1, foundation main body, internal surcharge 6 and external surcharge 7. Connection section 1 is a reinforced concrete cylinder; the foundation main body is located below the horizontal plane, including reinforced concrete cone 2, bottom plate 3, and side wall 5 And the rib 4, the bottom 3, the side wall 5 and the rib 4 are all reinforced concrete structures, the bottom of the reinforced concrete cone 2 is located at the center of the bottom 3, the side wall 5 is a cylindrical structure, located at the edge of the circular bottom 3, and the reinforcement In the annular space between the concrete cone 2 and the side wall 5, six ribs 4 are evenly distributed radially and radially, so that a plurality of independent cavities are formed between the side wall 5, the ribs 4 and the bottom plate 3, and the bottom plate 3, the ribs The slab 4,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com