Heat insulation and fire fighting smoke discharge system of steel structure roof

A technology of smoke exhaust system and heat insulation smoke exhaust air duct, which is applied in ventilation system, roof ventilation, heating method, etc., can solve the problems of ineffective smoke exhausting effect and poor indoor working environment, and achieve the effect of preventing smoke from being diffused.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the present invention.

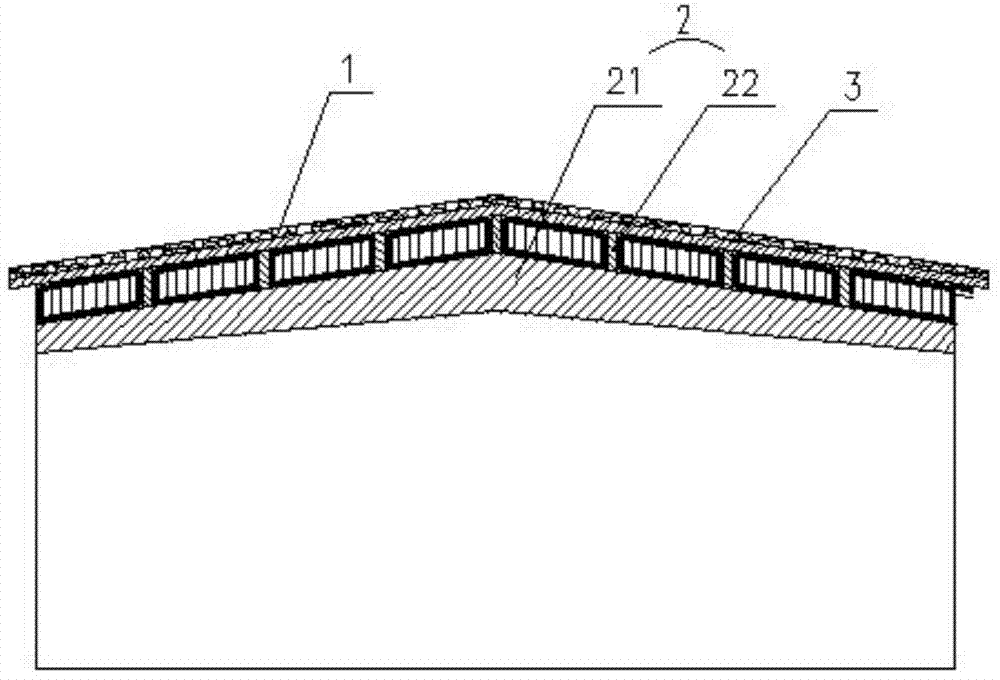

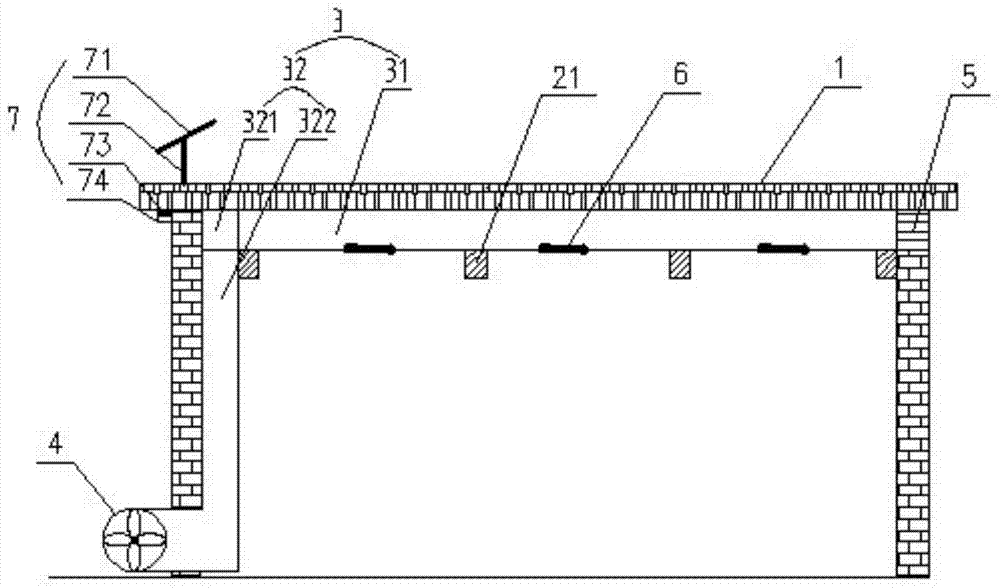

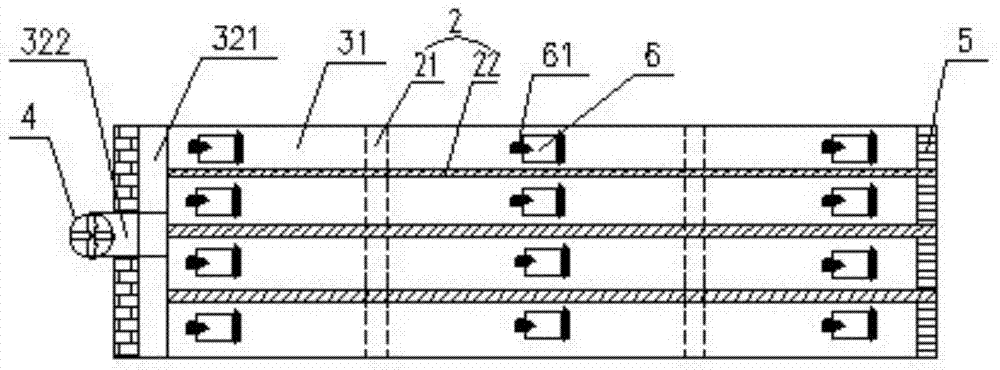

[0018] refer to figure 1 , figure 2 and image 3 As shown, a steel structure roof heat insulation and fire-fighting smoke exhaust system includes a roof 1 and a steel frame structure 2, and the steel frame structure 2 includes beams 21 and sandalwood bars 22. The steel structure roof heat insulation and fire-fighting and smoke exhaust system also includes a heat insulation and smoke exhaust duct 3 covering the entire roof and a fan 4 connecting the heat insulation and smoke exhaust duct 3 with the outdoor. The fan 4 is a two-speed fan. The heat insulation and smoke exhaust air duct 3 includes a plurality of roof air ducts 31 side by side and a centralized air duct 32 connected to one end of the plurality of roof air ducts 31; the other end of the roof air duct 31 is provided with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap