Overshot with slots for salvaging sucker rods

A technology of sucker rod and window opening, which is applied in wellbore/well parts, earthwork drilling and production, etc., which can solve the problems of cumbersome process, poor effect and high fishing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

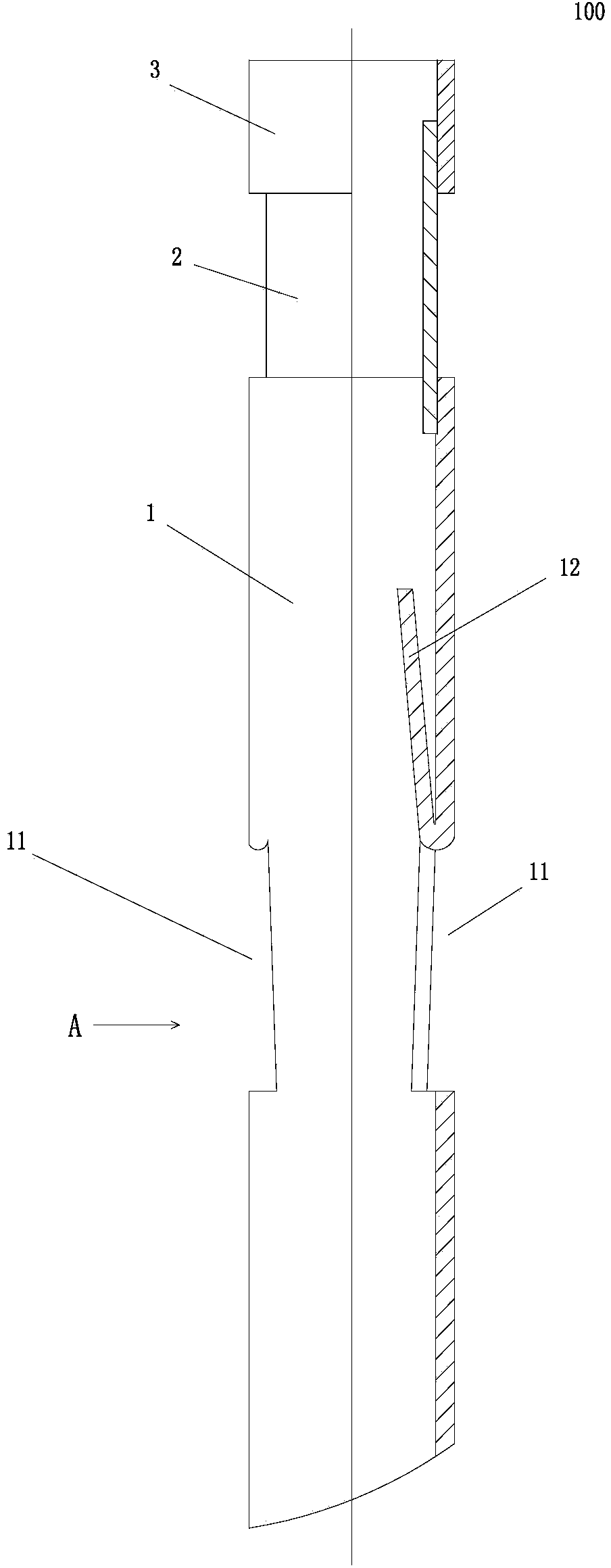

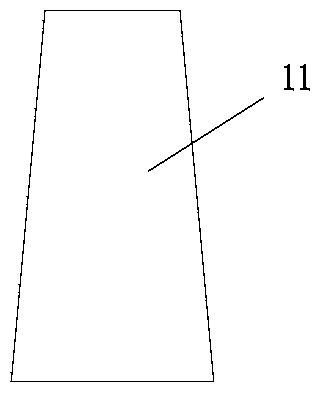

[0016] Such as figure 1 , figure 2 As shown, the present invention provides a fenestration overshot 100 for salvaging sucker rods. The fenestration overshot 100 includes a tubular overshot body 1, and a section of connecting tubing 2 is fixed on the upper part of the overshot body 1. The upper part of the connecting tubing 2 is fixedly connected with a short section 3 (the short section is connected with the tubing going down to the well during operation); two windows 11 are oppositely provided on the pipe wall of the overshot body 1; The window 11 is formed with a window tongue 12 inclined upward toward the inside of the overshot body; the distance between the tops of the two opposite window tongues 12 is smaller than the diameter of the coupl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com