Horizontal well external staged fracturing sand control string and method

A technology for staged fracturing and sand control pipes, which is applied in earth-moving drilling, wellbore/well components, wellbore/well valve devices, etc. Accidents, saving work time, the effect of large diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

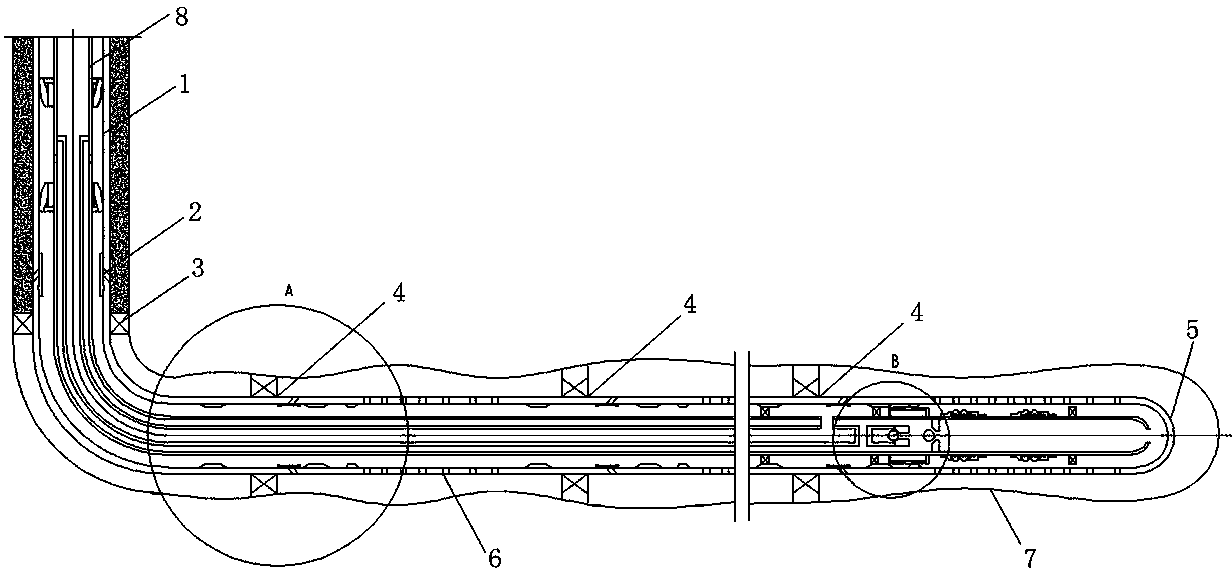

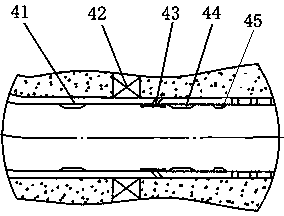

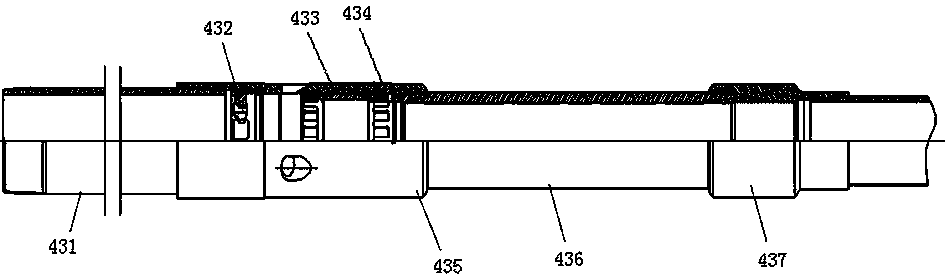

[0027] See Figure 1-Figure 5 , A horizontal well externally staged fracturing packing and sand control string, including external staged fracturing packing and sand control staying pipe string and packing service string. The packing service string pipe 8 is lowered to the outside of the pipe for staged fracturing The filling and sand control staying well string is characterized in that the external fracturing filling and sand control staying well string includes a technical casing 1 and a cementing grading hoop connected sequentially thereon 2, a cementing external packer 3 , Filling tool assembly 4, screen 6 and guide shoe 5; The filling service pipe string 8 includes a liquid barrier sealing device 10 and its lower part are sequentially installed and connected to the filling tube 11, the liquid barrier 12, and the filling conversion device 13 , Flexible pressure measuring device 14, rotary positioning tool 15, sliding sleeve closing tool 16, sliding sleeve switch tool 17, is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com