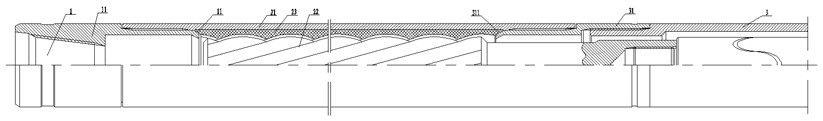

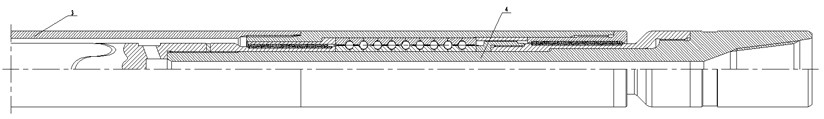

Wear-resistant and erosion-resistant screw drill for in-situ mining of oil shale and machining technology

A technology for in-situ mining and screw drilling tools, which is used in earth-moving drilling, drilling equipment, directional drilling, etc., and can solve problems such as motor failure, high well pressure, and long operating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The processing technology of wear-resistant and corrosion-resistant screw drilling tools for in-situ mining of oil shale includes the following process steps:

[0026] (1), making non-rubber synthetic inner bushing:

[0027] Add 10% polytetrafluoroethylene, 12% 3-12mm aramid fiber 1313, 10% silicon carbide fiber with a diameter of 0.5-1.2μm and a length of 30-160μm, and 15% polymethyl methacrylate into the mixer High-speed mixing and stirring for 0.5h, high-speed shearing, adding 35% styrene to the evenly stirred mixture, adding 3% diethylenetriamine solubilizer, 5% molybdenum disulfide additive, 4% vulcanization accelerator, Put 4% dioctyl sebacate softener into the internal mixer at a temperature of 210°C, vulcanize after mixing for 2 hours, vulcanize for 12 hours, and vulcanize at a temperature of 160°C to make a non-rubber synthetic inner lining;

[0028] (2) Make the motor stator metal shell, motor rotor and rubber locking sleeve, set a locking slope at the end of...

Embodiment 2

[0032] The processing technology of wear-resistant and corrosion-resistant screw drilling tools for in-situ mining of oil shale includes the following process steps:

[0033] (1), making non-rubber synthetic inner bushing:

[0034] Add 15% polytetrafluoroethylene, 8% aramid fiber 1313 3-12mm, 15% silicon carbide fiber with a diameter of 0.5-1.2μm and a length of 30-160μm, and 19% polymethyl methacrylate into the mixer High-speed mixing and stirring for 0.5h, high-speed shearing, adding 30% styrene to the evenly stirred mixture, adding 4% diethylenetriamine solubilizer, 4% molybdenum disulfide additive, 3% vulcanization accelerator, Put 2% dioctyl sebacate softener into the internal mixer at a temperature of 25°C, vulcanize after mixing for 2 hours, vulcanize for 12 hours, and vulcanize at a temperature of 180°C to make a non-rubber synthetic inner lining;

[0035] (2) Make the motor stator metal shell, motor rotor and rubber locking sleeve, set a locking slope at the end of t...

Embodiment 3

[0039] The processing technology of wear-resistant and corrosion-resistant screw drilling tools for in-situ mining of oil shale includes the following process steps:

[0040] (1), making non-rubber synthetic inner bushing:

[0041] Add 10% polytetrafluoroethylene, 10% 3-12mm aramid fiber 1313, 18% silicon carbide fiber with a diameter of 0.5-1.2μm and a length of 30-160μm, and 20% polymethyl methacrylate into the mixer High-speed mixing and stirring for 0.5h, high-speed shearing, adding 30% styrene to the evenly stirred mixture, adding 3% diethylenetriamine solubilizer, 2% molybdenum disulfide additive, 5% vulcanization accelerator, Put 2% dioctyl sebacate softener into the internal mixer at a temperature of 280°C, vulcanize after mixing for 2.5 hours, vulcanize for 12 hours, and vulcanize at a temperature of 190°C to make a non-rubber synthetic inner lining;

[0042] (2) Make the motor stator metal shell, motor rotor and rubber locking sleeve, set a locking slope at the end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com