Electric control device of engine extinguisher and control method of engine extinguisher

A technology of electronic control device and flame extinguisher, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc. It can solve the problems of motor overshoot, no electrical signal acquisition, device burnout, etc., to improve reliability and avoid contact Sticking, the effect of reducing the motor speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

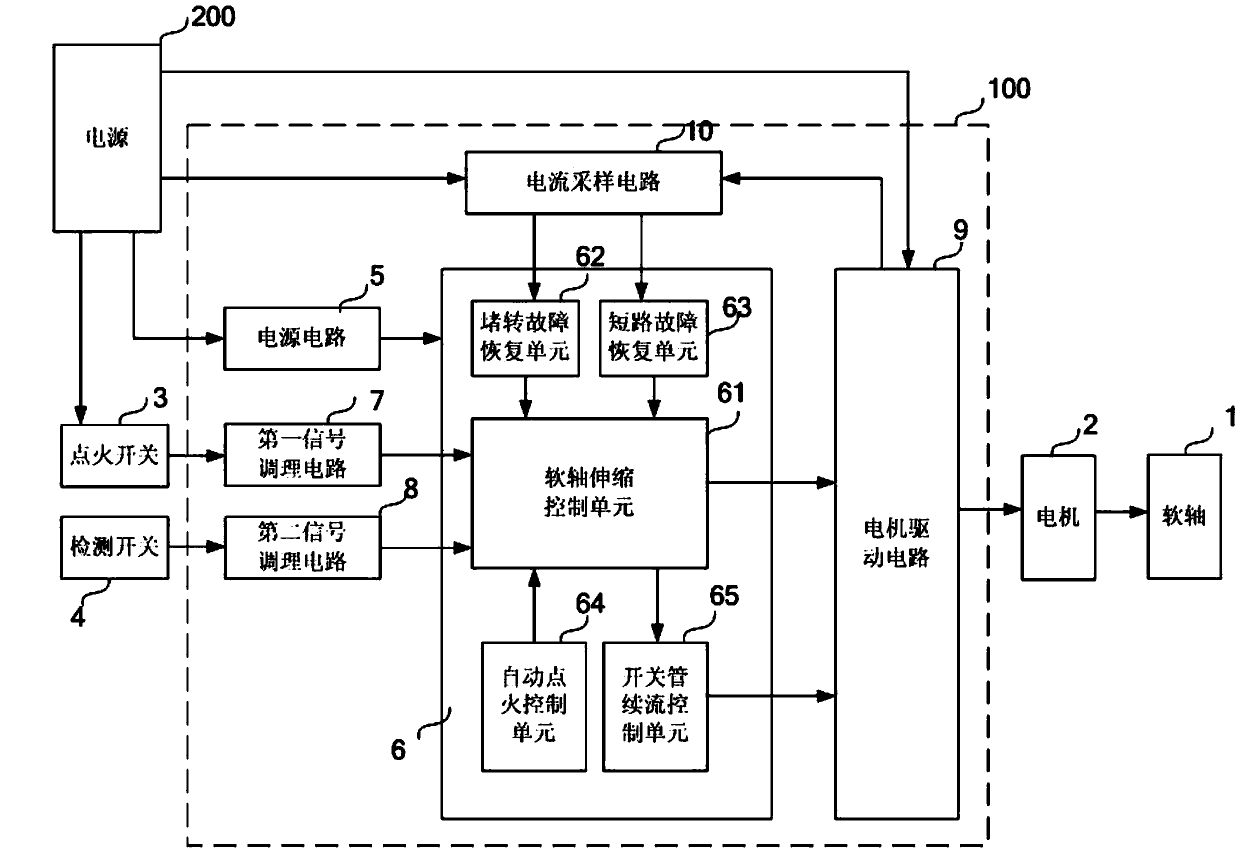

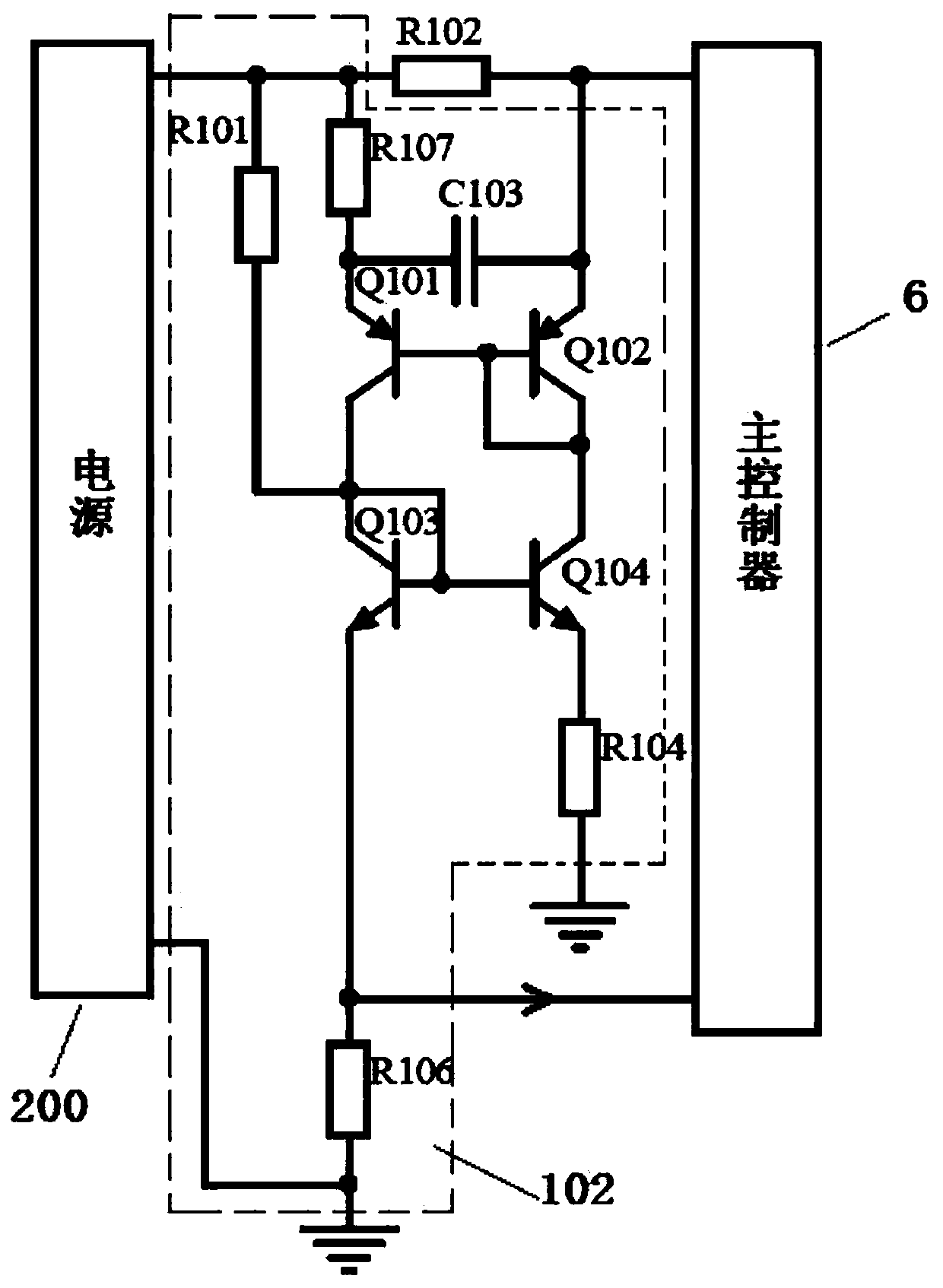

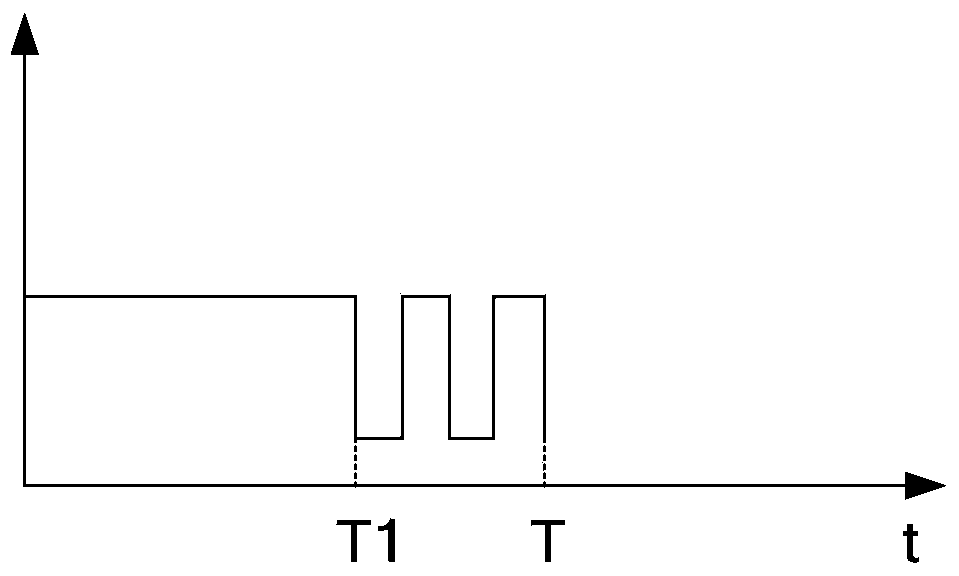

[0024] Please refer to figure 1 . The engine flame extinguisher includes a flexible shaft 1, a motor 2 for driving the flexible shaft 1 to extend and retract, a detection switch 4 and an electric control device 100 that are turned on and off triggered by the extension and retraction of the flexible shaft. The vehicle body power supply 200 supplies power to the engine flame extinguisher. According to an embodiment of the present invention, the electronic control device 100 of a flame extinguisher includes a power supply circuit 5, a main controller 6, a first signal conditioning circuit 7, a second signal conditioning circuit 8, and a motor drive capable of driving the motor 2 forward and reverse. The circuit 9 and the current sampling circuit 10 for collecting the driving current of the motor. The vehicle body power supply 200 supplies power to the ignition switch 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com