Bayonet-tube collecting and distributing tube for automotive parallel flow evaporator

A parallel flow and evaporator technology, which is applied in the field of intubation type collecting and shunt pipes, can solve the problems of poor flow distribution uniformity and affect the heat exchange performance of heat exchangers, achieve uniform flow distribution, improve flow distribution uniformity, and be easy to popularize and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

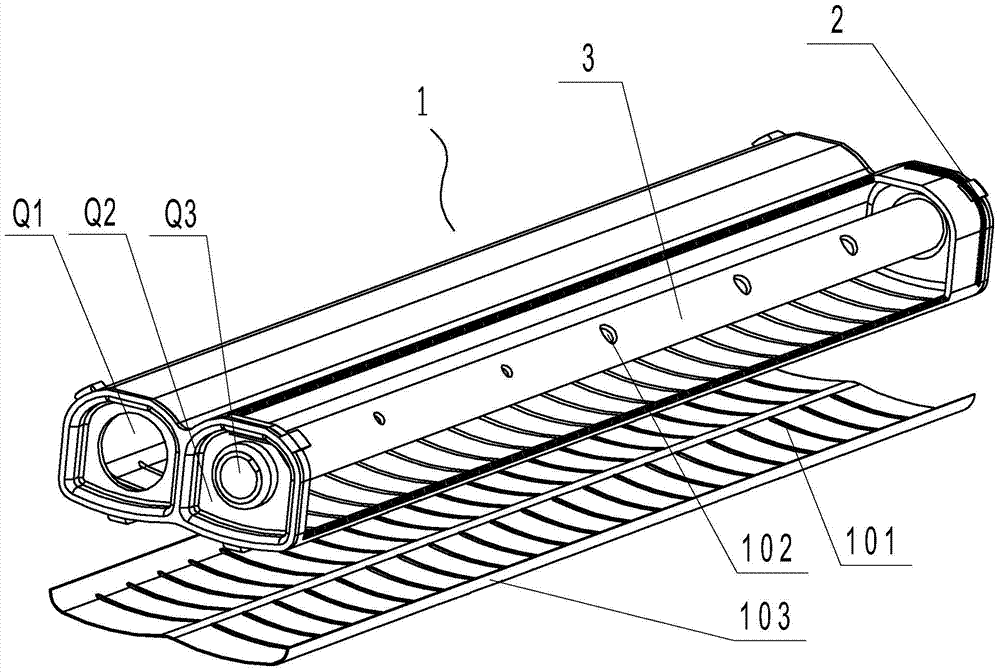

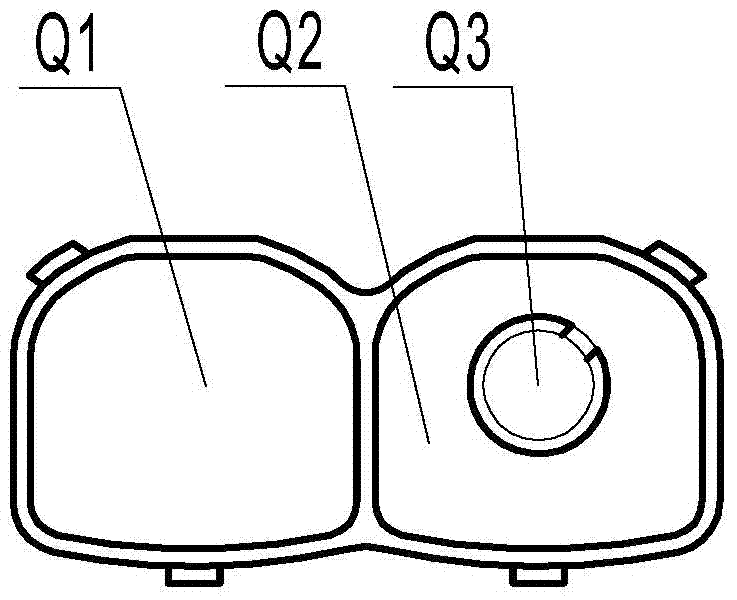

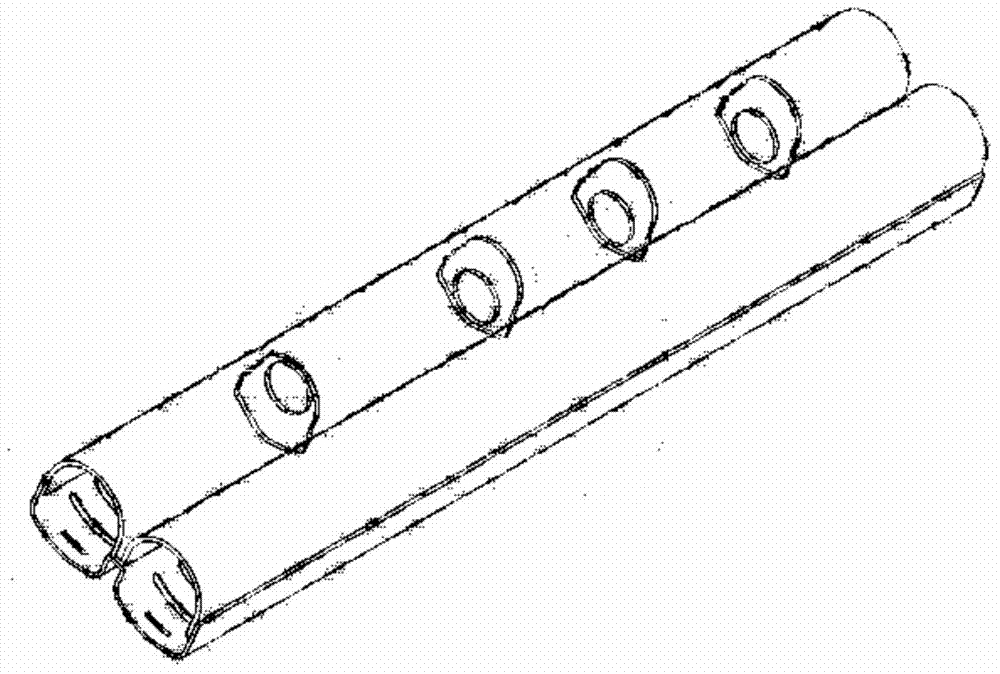

[0021] Figure 1-Figure 2 Disclosed in is an intubated collector-distributor tube for parallel-flow evaporators for vehicles, which includes an integral tube body 1, the two ends of the tube body 1 are respectively inserted into the grooves of the end cover 2, and the inside of the tube body 1 is arranged along the axial direction. There are two independent inner cavities: two independent inner cavities: the first manifold Q1, the second manifold Q2, and the bottoms of the first manifold Q1 and the second manifold Q2 are evenly distributed with harmonica tube installation hole 107, a shunt pipe 3 parallel to the second manifold is inserted longitudinally in the second manifold Q2, and the inner cavity of the shunt pipe 3 forms a shunt chamber Q3, and the shunt pipe 3 is provided with a shunt The cavity Q3 communicates with the flow hole 108 of the second manifold Q2. The pipe body 1 is also equipped with a welding piece 109 which is convenient for welding with external compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com