Method for predicting fatigue crack expanding threshold value under different stress ratios

A fatigue crack growth and stress ratio technology, applied in the field of mechanical properties, can solve the problems of high cost, long cycle, inability to predict the threshold value of fatigue crack growth, etc., to save costs, reduce test workload, and achieve the effect of good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment the present invention is described in further detail:

[0024] Step 1: According to the national standard GB / T6398-2000 "Metallic Material Fatigue Crack Growth Rate Test Method", at room temperature, the material stress ratio R 0 The fatigue crack growth threshold of the next sample is tested to obtain the relationship between the fatigue crack growth rate da / dN and the stress intensity factor amplitude ΔK, and the test data points da / dN~ΔK are required to include fatigue crack stability in the double-logarithmic coordinate system Expansion zone and near-threshold zone;

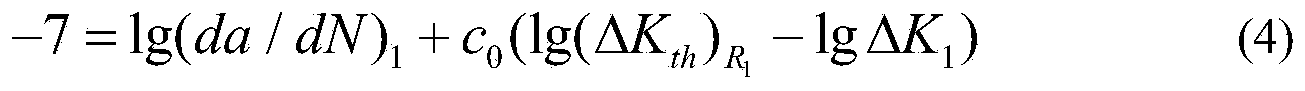

[0025] Step 2: In the log-logarithmic coordinate system, determine the fitting slopes of the data points in the fatigue crack stable growth zone and the near-threshold zone as b 0 and c 0 , and the intersection point of the two is the coordinate ((da / dN) 0 , ΔK 0 );

[0026] Step 3: According to different stress ratios, the maximum stress intensity fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com