Hardware-in-loop testing device and method for vehicle-mounted battery charger control device of new-energy automobile

A vehicle-mounted charger and control device technology, applied in the direction of electrical testing/monitoring, etc., can solve problems such as irrational logic, damage to the high-voltage system of the car, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

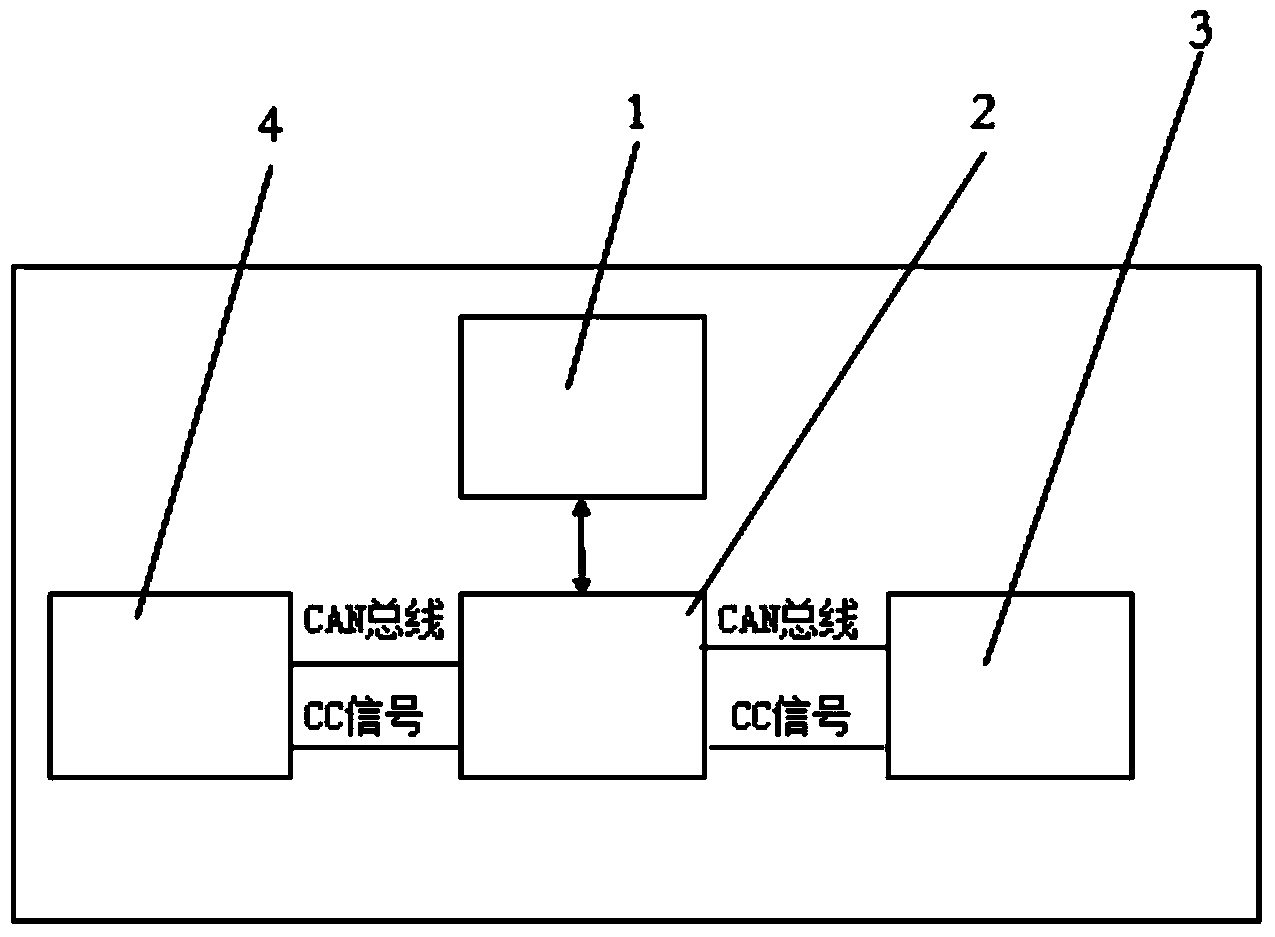

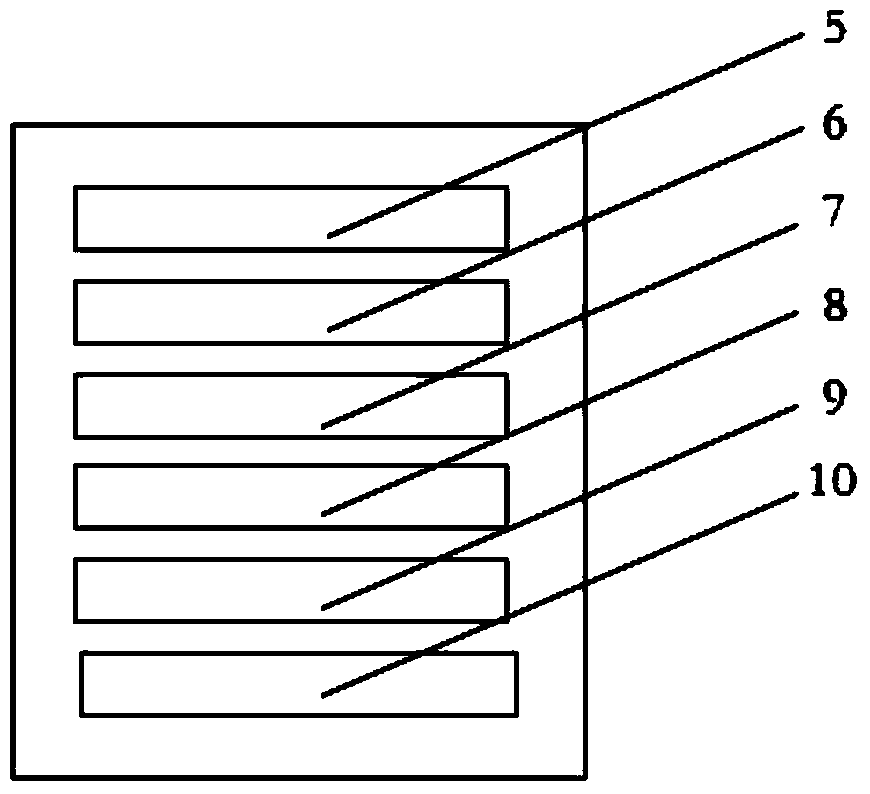

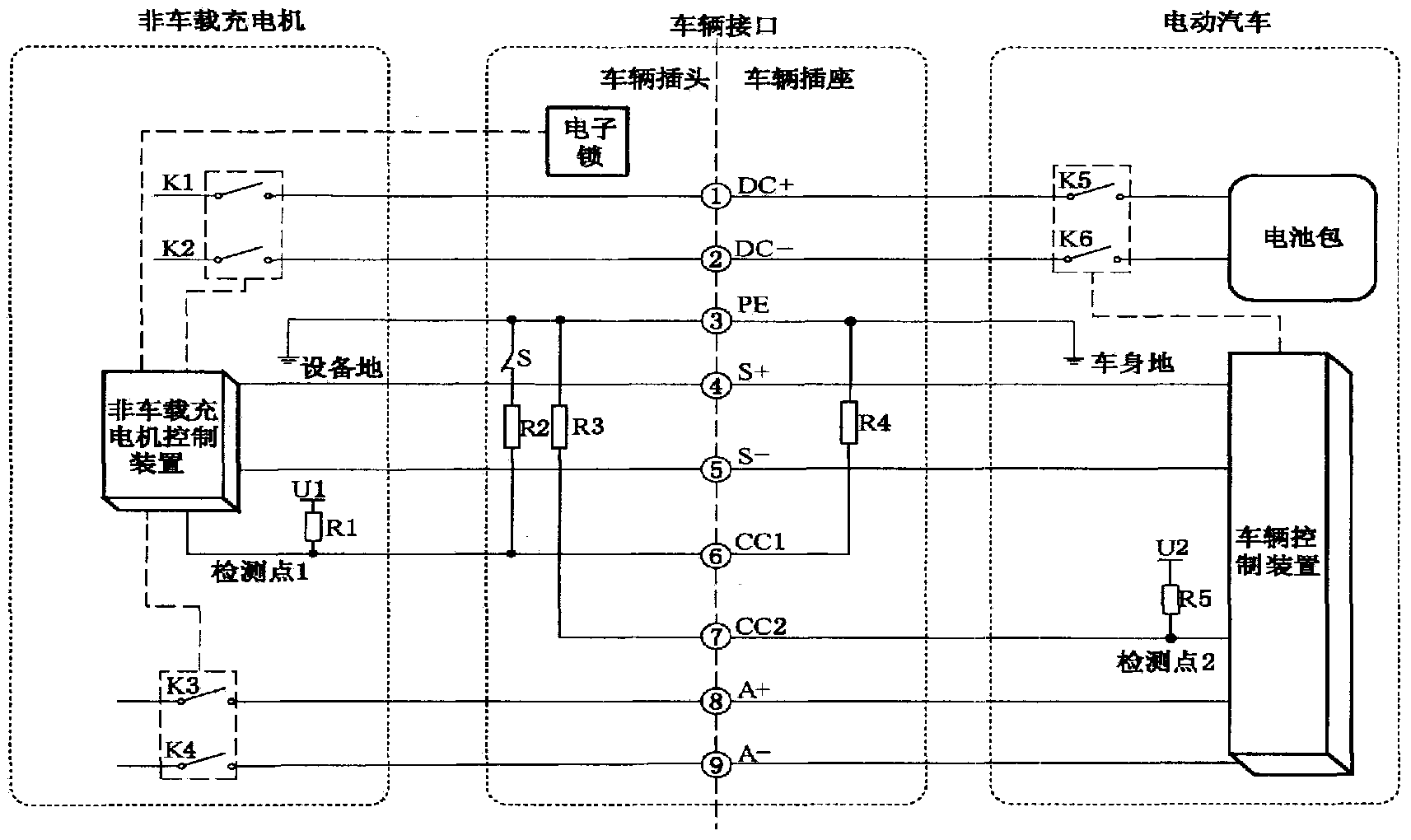

[0028] Such as Figure 1-4 As shown, a hardware-in-the-loop testing device for a new energy vehicle on-board charger control device described in an embodiment of the present invention includes a test host computer interface 1, a LABCAR system 2, an on-board charger control device 3, and a battery management system 4. The LABCAR system 2 includes a programmable power supply 5, a real-time simulation computer 6, a resistance signal simulation board 7, a bus signal simulation board 8, a fault simulation board 9 and a PWM signal simulation board 10; the test host computer interface 1 passes through a network cable The LABCAR system 2 is connected, and the LABCAR system 2 communicates with the on-board charger control device 3 and the battery management system 4 through the CAN bus, PWM signals, and digital control signals.

[0029] A hardware-in-the-loop test method for a new energy vehicle on-board charger control device and a battery management system described in an embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com