A multi-moving platform micro-nano scale moving and sample manipulation device

A micro-nano, actuator technology, applied in the direction of control using feedback, etc., can solve the problems of no intellectual property rights, high prices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are exemplified and described in detail below with the accompanying drawings.

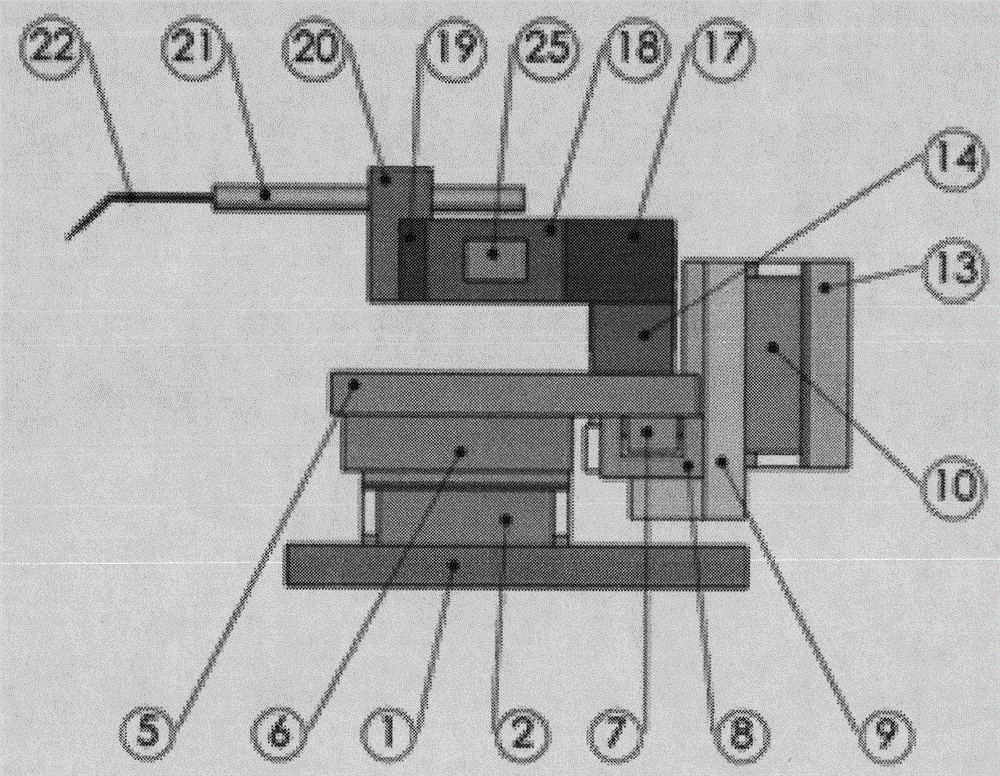

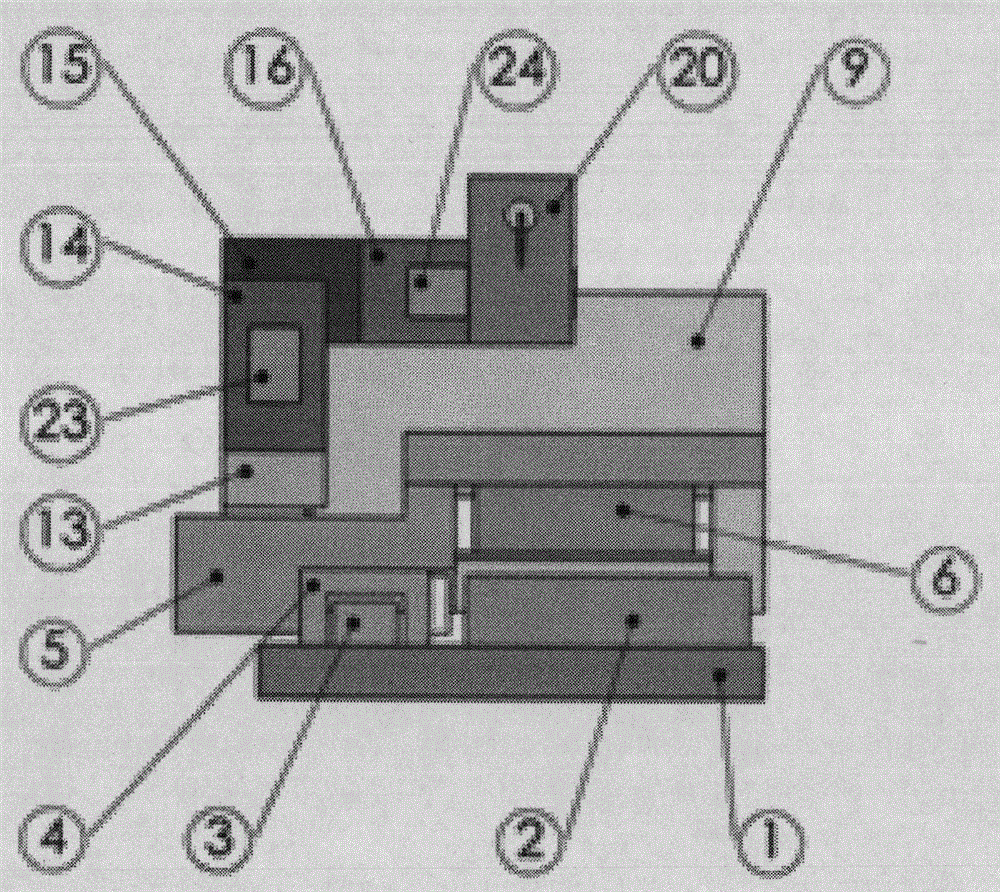

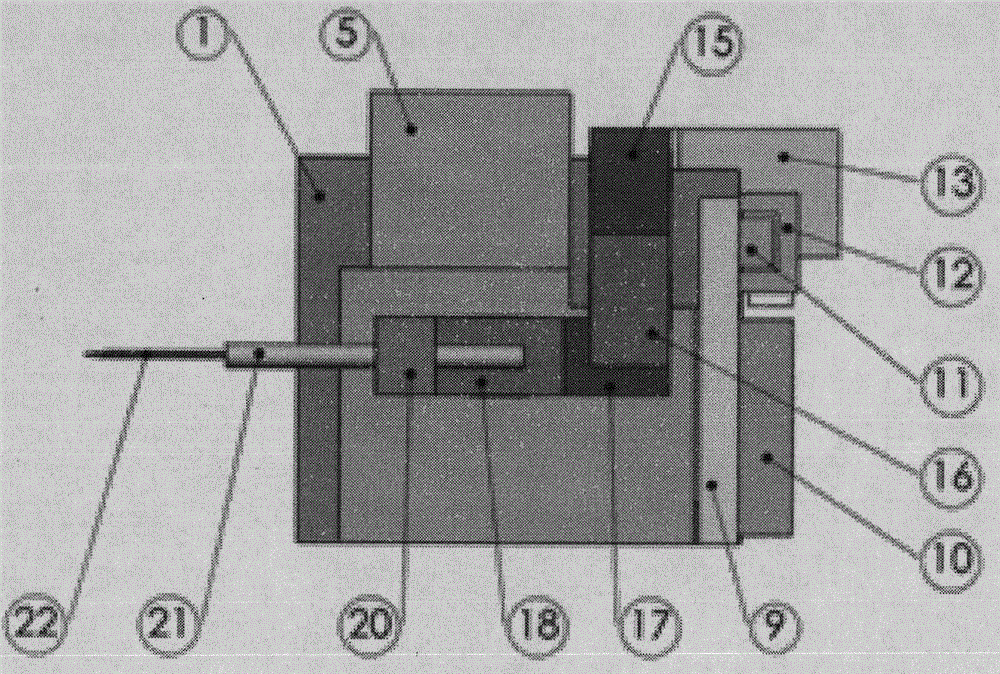

[0021] see Figure 1-Figure 3 :

[0022] like Figure 1-Figure 3 As shown in the figure, the multi-moving platform micro-nano-scale movement and sample manipulation device in the embodiment of the present invention is mainly composed of a Y-axis base 1, a Y-axis vacuum piezoelectric ceramic linear motor 2, a Y-axis slider guide 3, a Y-axis slider 4, a X-axis Axis base 5, X-axis vacuum piezoelectric ceramic linear motor 6, X-axis slider guide 7, X-axis slider 8, Z-axis base 9, Z-axis vacuum piezoelectric ceramic linear motor 10, Z-axis slider guide 11, Z Axis slider 12, Z axis fine adjustment bracket 13, Z axis piezoelectric ceramic actuator 14, X axis fine adjustment bracket 15, X axis piezoelectric ceramic actuator 16, Y axis fine adjustment bracket 17, Y axis piezoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com