Modified lithium nickel-cobalt-manganese ternary positive electrode material and preparation method thereof

A lithium-nickel-cobalt-manganese ternary and positive electrode material technology, which is applied in the field of lithium-ion batteries, can solve problems such as the structure of lithium-nickel-cobalt-manganese ternary positive electrode materials that are easily damaged, the content of impurity lithium increases, and the discharge specific capacity of lithium-ion batteries decays. , to achieve the effect of improving cycle performance, reducing reaction, and facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

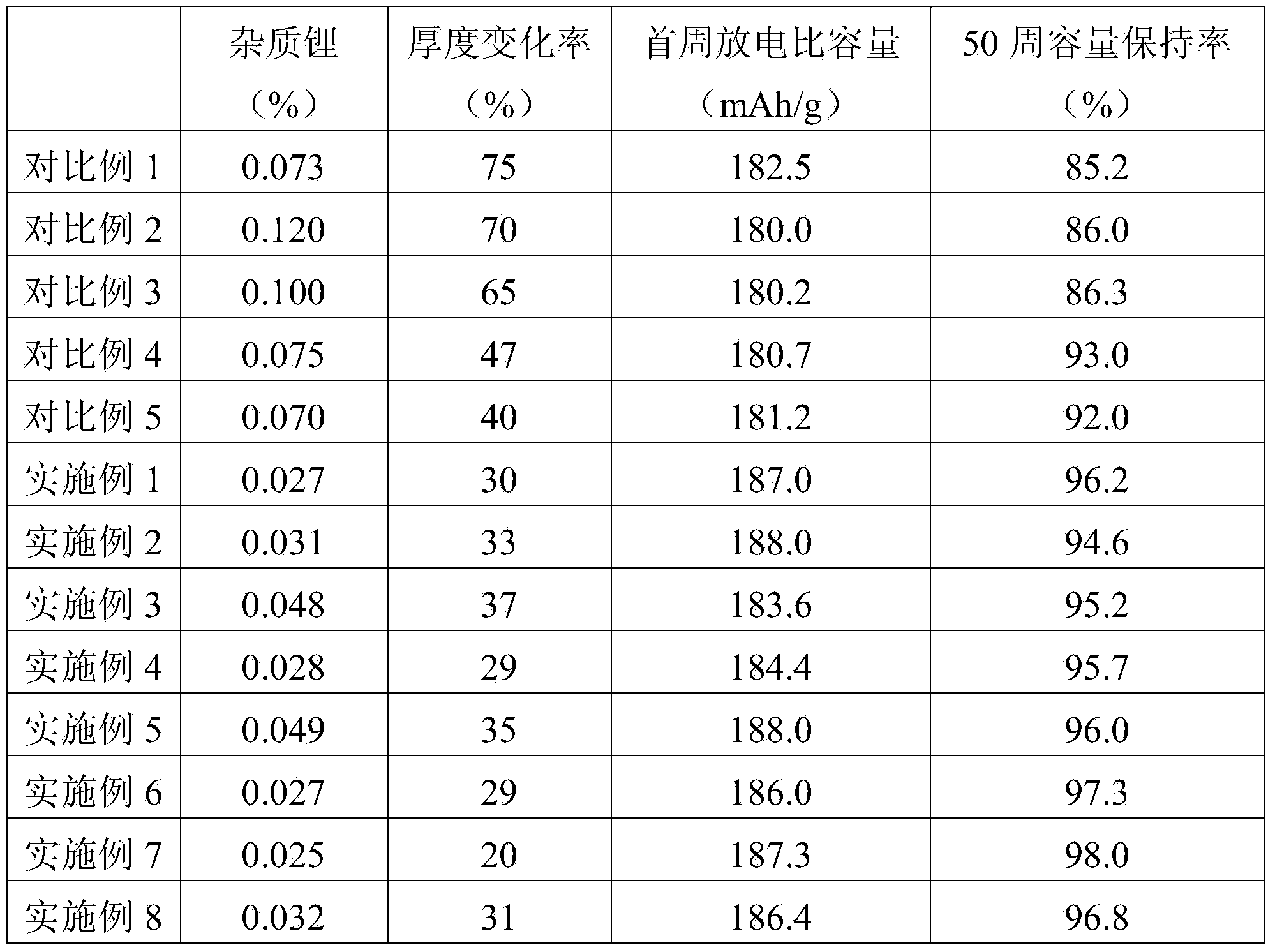

Examples

preparation example Construction

[0015] The preparation method of the modified lithium-nickel-cobalt-manganese ternary positive electrode material according to the second aspect of the present invention comprises the steps of: (1) adding lithium salt and M salt into an organic solvent, and continuously stirring until the lithium salt and M salt are fully dissolved in an organic solvent to obtain a homogeneous solution, then add the N salt into the obtained homogeneous solution, continuously stir for 0.5h to 8h, then add lithium nickel cobalt manganese ternary positive electrode material, and continue to stir for 2h to 6h to obtain a mixed solution, wherein The molar ratio of the lithium element in the lithium salt, the M element in the M salt, and the N element in the N salt is x:y:1, 0x m y NO 3 A coated lithium-nickel-cobalt-manganese ternary cathode material, wherein 0

[0016] In the preparation method of the modified...

Embodiment 1

[0034] Add 0.004g of lithium nitrate and 0.302g of lanthanum nitrate hexahydrate into 253ml of absolute ethanol, stir until lanthanum nitrate hexahydrate and lithium nitrate are fully dissolved in absolute ethanol; continue to add 0.305g of isopropyl titanate, stir for 3h, and form Milky white liquid, LiNi 0.5 co 0.2 mn 0.3 o 2 Add the ternary positive electrode material into the milky white liquid, and continue to stir for 4 hours to obtain a mixed solution; filter the mixed solution with suction, dry the obtained filter cake in an oven, heat to 600°C in an oxygen-containing atmosphere, and keep it at 600°C for 4 hours. That is, the amorphous Li 0.05 La 0.65 TiO 3 Coated lithium nickel cobalt manganese ternary cathode material (i.e. modified lithium nickel cobalt manganese ternary cathode material), in which the amorphous Li 0.05 La 0.65 TiO 3 The weight accounts for the total weight of the modified lithium-nickel-cobalt-manganese ternary cathode material (that is, th...

Embodiment 2

[0036] Add 0.048g of lithium nitrate and 0.299g of lanthanum nitrate hexahydrate into 253ml of absolute ethanol, stir until lanthanum nitrate hexahydrate and lithium nitrate are fully dissolved in absolute ethanol; continue to add 0.393g of isopropyl titanate, stir for 3h, and form Milky white liquid, LiNi 0.5 co 0.2 mn 0.3 o 2 Add the ternary positive electrode material into the milky white liquid, continue stirring for 4 hours to obtain a mixed solution; filter the mixed solution with suction, dry the obtained filter cake in an oven, heat to 600°C in an oxygen-containing atmosphere, and keep warm at 600°C for 4 hours, that is Amorphous Li 0.5 La 0.5 TiO 3 Coated lithium nickel cobalt manganese ternary cathode material (i.e. modified lithium nickel cobalt manganese ternary cathode material), in which the amorphous Li 0.5 La 0.5 TiO 3 The weight accounts for the total weight of the modified lithium-nickel-cobalt-manganese ternary cathode material (amorphous Li 0.5 La ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap