Printed board open hole printing ink filling method and hole filling breathable board

A filling method and printed board technology, which is applied in the direction of printed circuit components, electrical connection formation of printed components, etc., can solve the problem of uneven local force, and achieve the effect of improving quality, strengthening support force, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

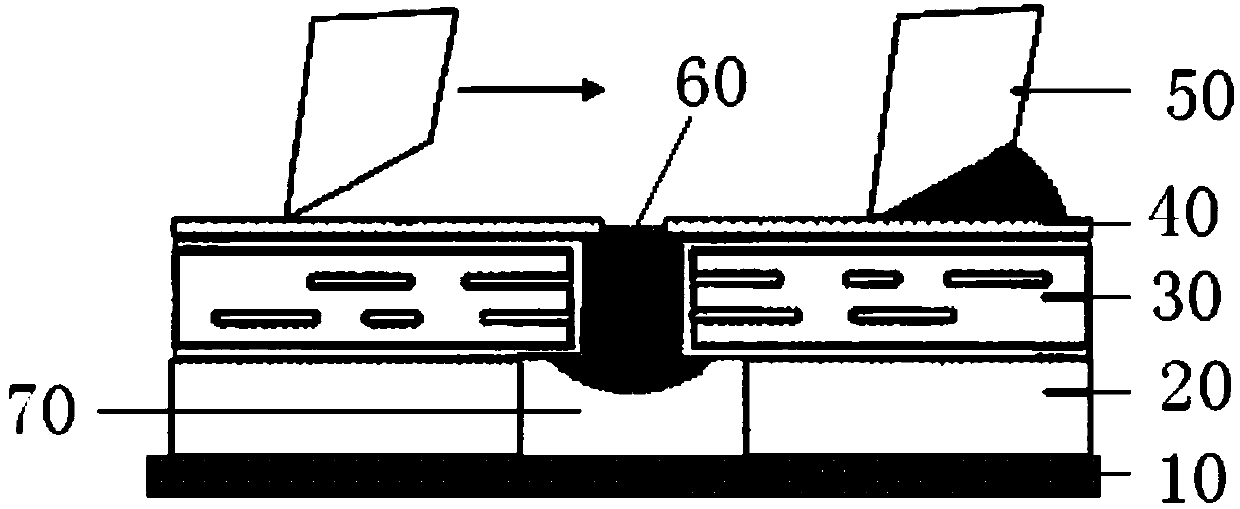

[0026] As mentioned above, in the prior art, after the through-holes are drilled on the epoxy gas-permeable panels, the tiny joints are easy to break and generate debris, which affects the quality of the plug holes and the cleanliness of the purification workshop. After drilling through holes, there will be local voids in the air-permeable board, which will have a great impact on the support of the printed board surface when the holes are plugged, and the force on the board surface will be uneven when the plug holes are scraped (see the profile Figure 5 ), when the resin plugs the hole, there will be some problems that the plug cannot be partially plugged, and too much oil will be emitted locally.

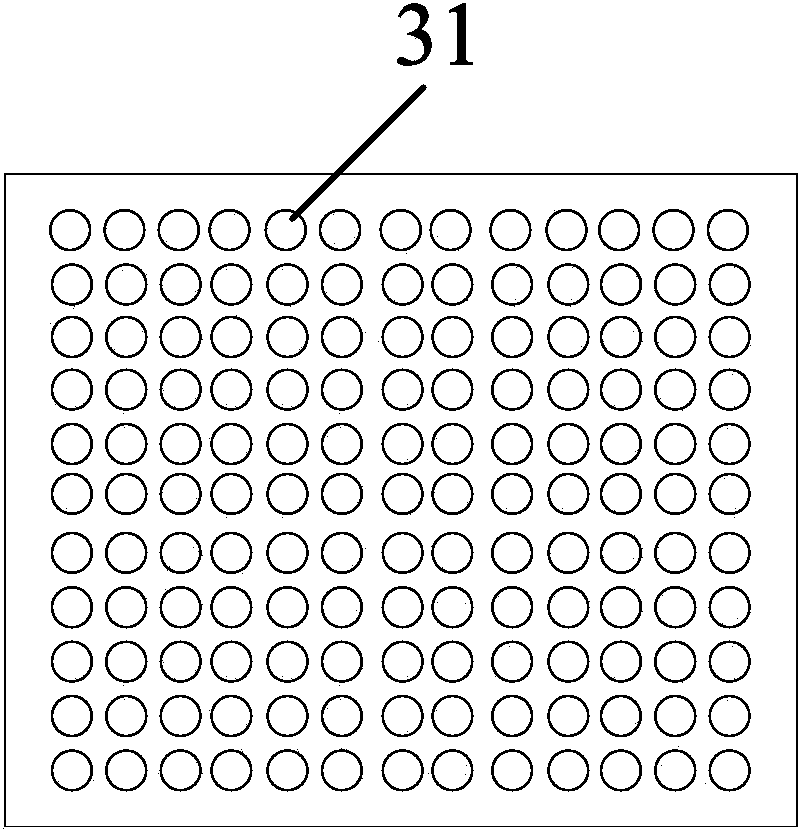

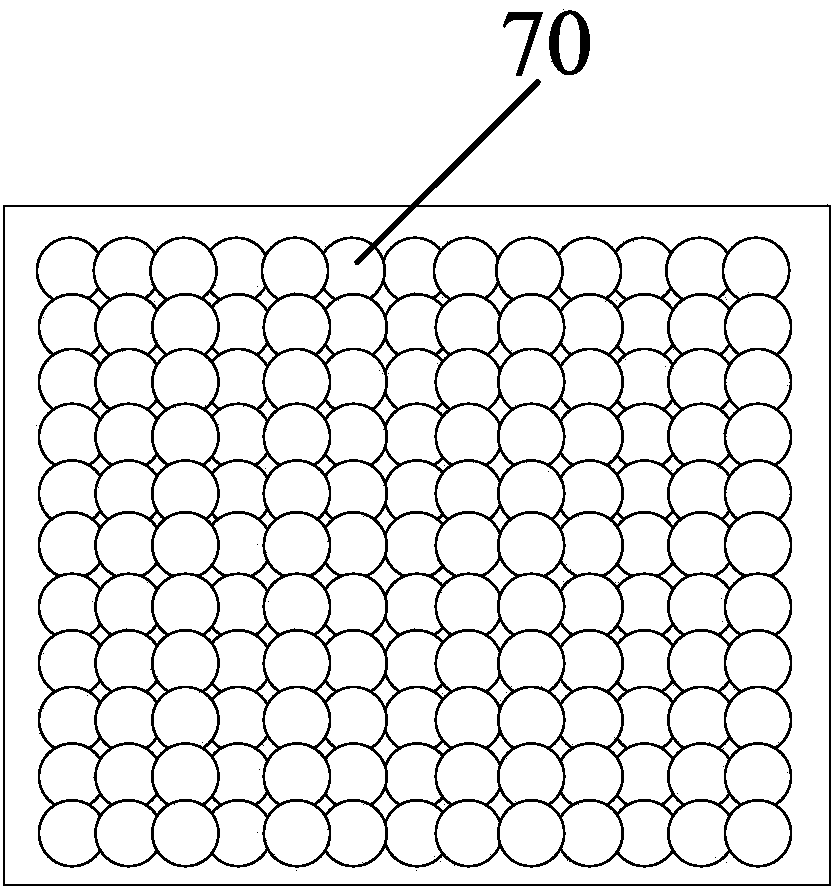

[0027] Figure 6 to Figure 9 A schematic dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com