Method for cooling a fuel cell

A fuel cell and coolant technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as being expensive and prone to failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

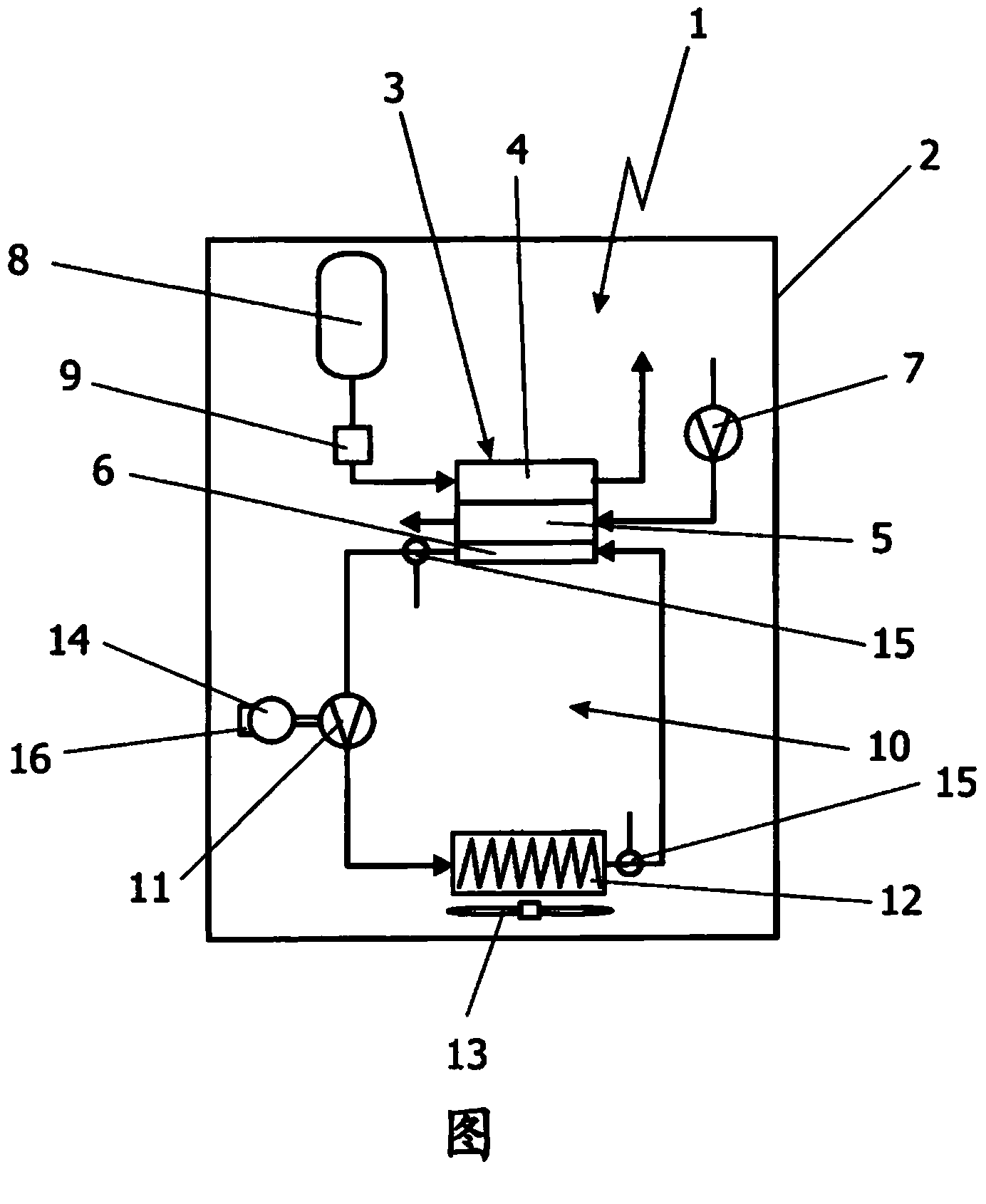

[0014] In the single attached figure, the fuel cell system 1 can be seen in a very strongly schematic view. In this case, the fuel cell system 1 is designed for installation in the indicated vehicle 2 . The core of the fuel cell system 1 is the fuel cell 3 , which should be designed as a PEM fuel cell by way of example. In its interior, the fuel cell 3 essentially has three spaces arranged separately from one another, which are each realized in the usual construction in individual cells which are then stacked to form a fuel cell group, the so-called stack. The individual spaces of the cells of the fuel cell stack 3 are then connected to one another via corresponding line elements or current collectors. Here, the spaces shown in the figure are positive electrode chamber 4 , negative electrode chamber 5 , and space 6 through which a liquid cooling medium flows in the example of a battery cell, and this space may also be called a heat exchanger for cooling. The negative electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com