Recovery system for environmental protection oil paint

A recycling system and environmental protection technology, applied in the direction of spray booth, spray device, device for coating liquid on the surface, etc., can solve the problems of raw material waste, environmental pollution, ecological environment impact, etc., to avoid environmental pollution problems and reduce spray paint raw materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

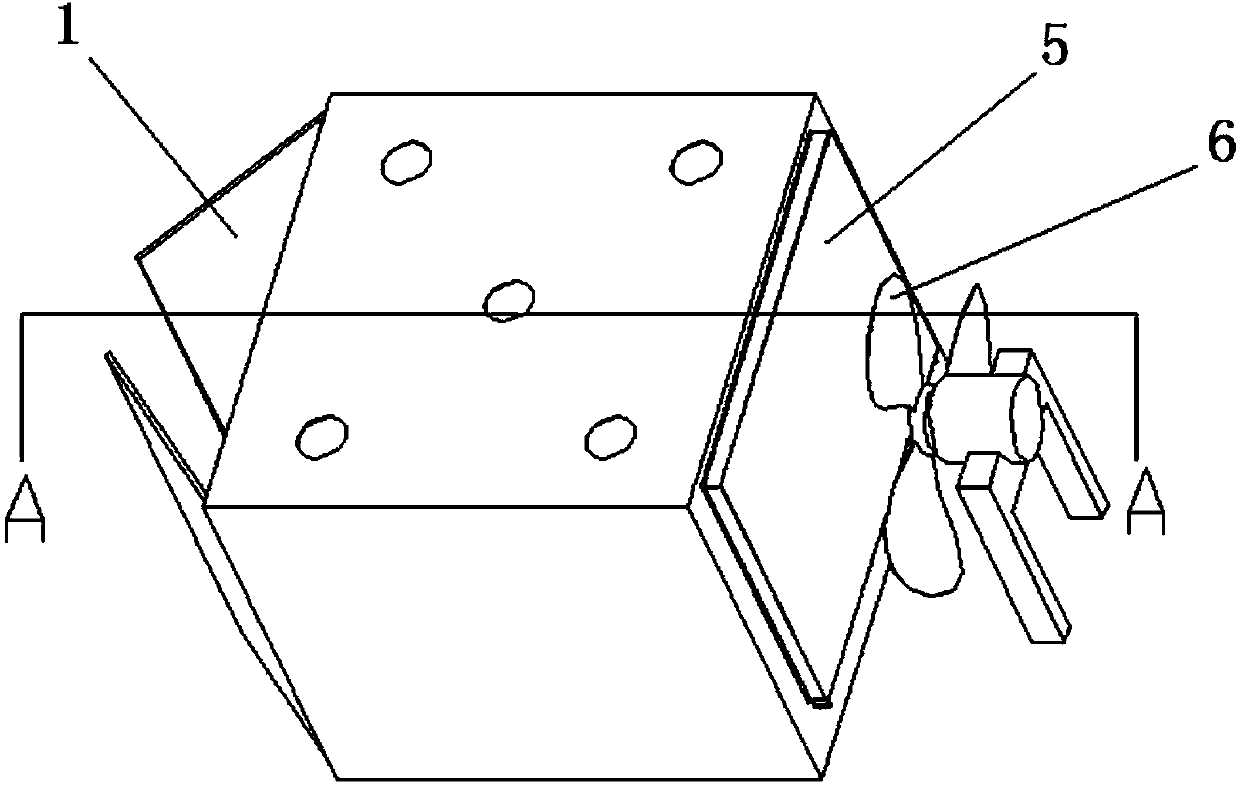

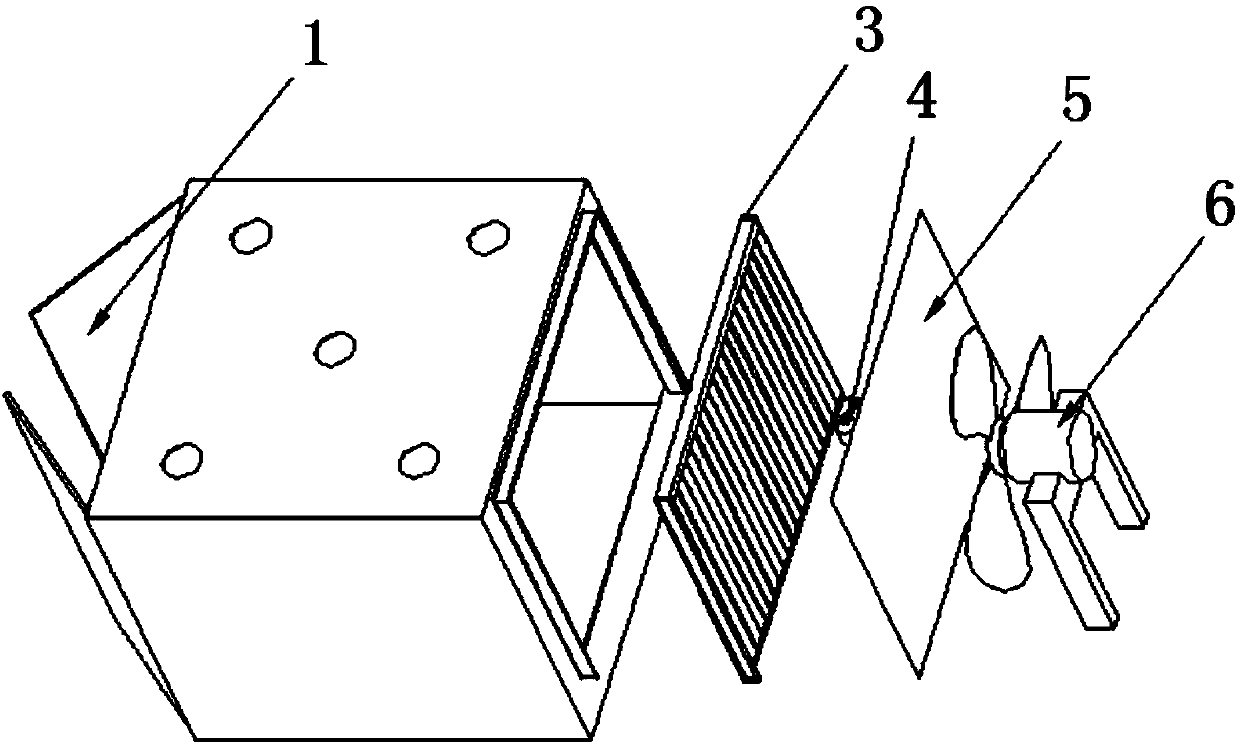

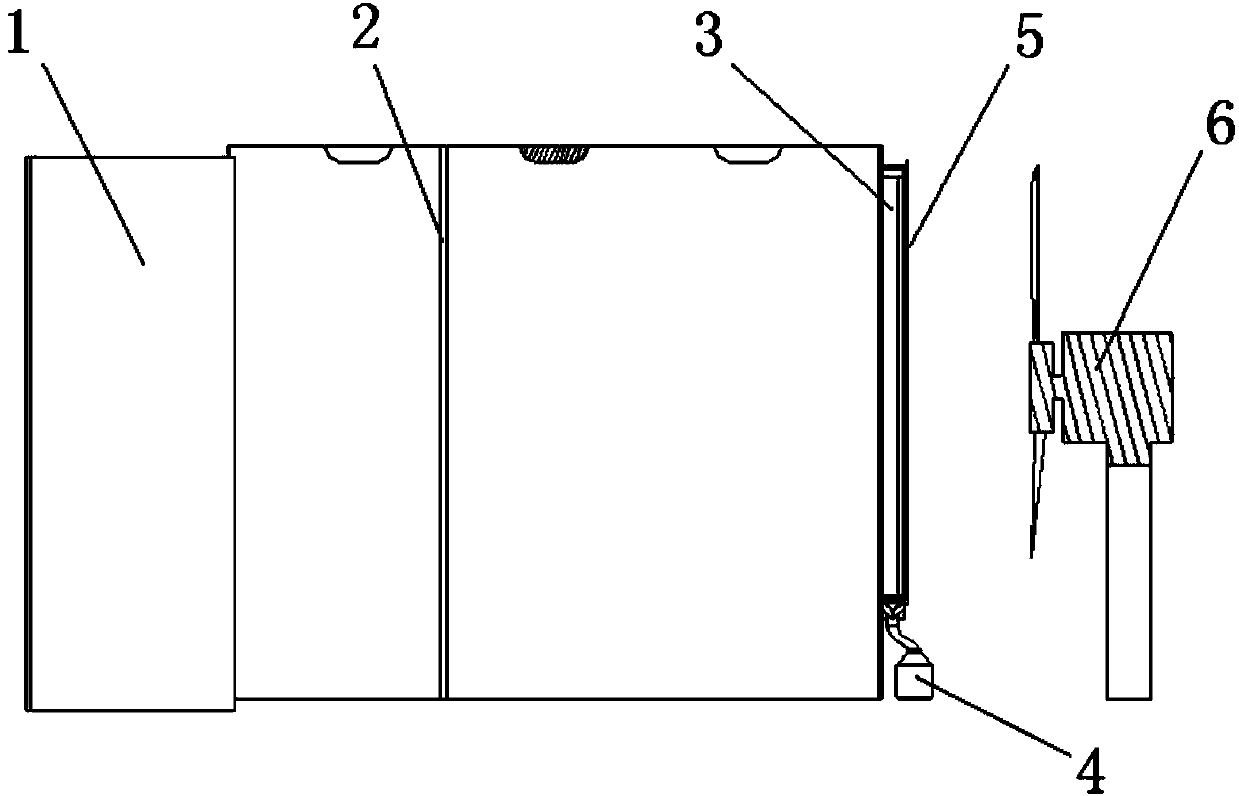

[0018] The following is the specific implementation manner of a preferred embodiment of the present invention, as Figure 1 to Figure 6 shown. An environment-friendly spray paint recovery system, the system is channel-type, and double-door light-isolation devices for making an anti-exposure darkroom environment operating space are arranged in sequence in the channel, and the double doors are outer door 1 and inner door 2 respectively; A paint recovery device 3 for recovering paint by means of surface adhesion. The paint recovery device 3 is formed by multiple groups of vertically arranged stainless steel plates in the shape of fretwork without contact and nesting; The paint anti-leakage filtering device of the paint, and the ventilation device, the ventilation device is made up of the suction fan 6 and a support; the recovery paint storage device 4 for receiving the recovered paint is also provided at the bottom of the paint recovery device. Under the guidance of the wind dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com