Feeding device for high-speed aluminum fin belt rolling machine

A technology of feeding device and aluminum fins, which is applied in the directions of feeding device, positioning device, storage device, etc., can solve the problems of large diameter of aluminum strip tray, time-consuming and laborious operation of the tray, and unstable operation, so as to avoid slipping and slipping. , compact structure, fast replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

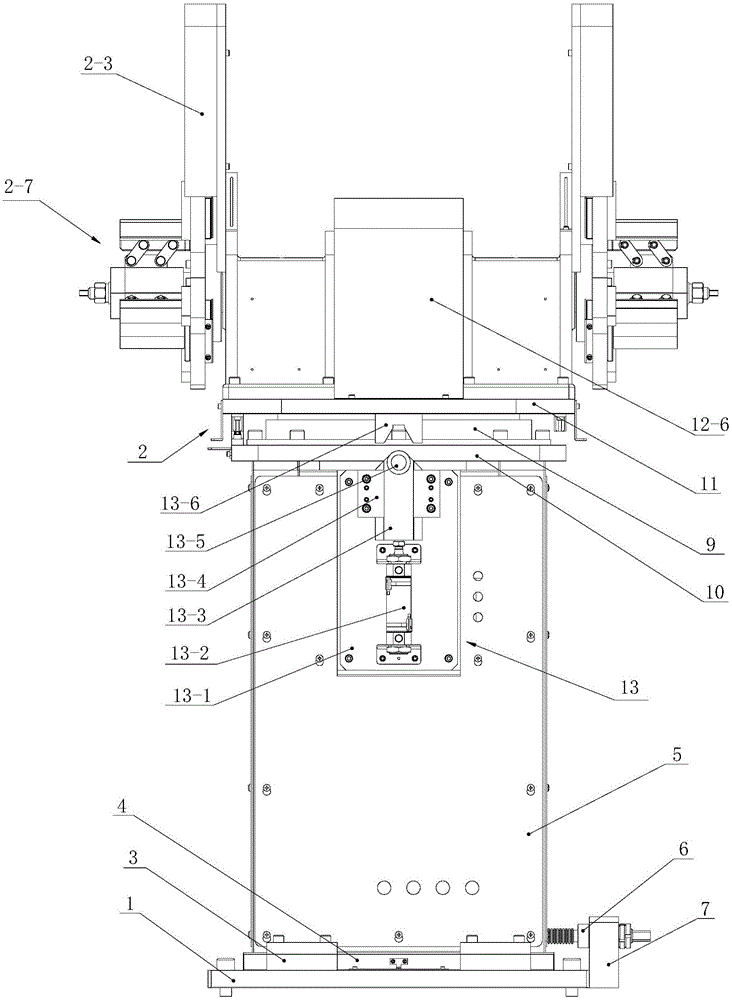

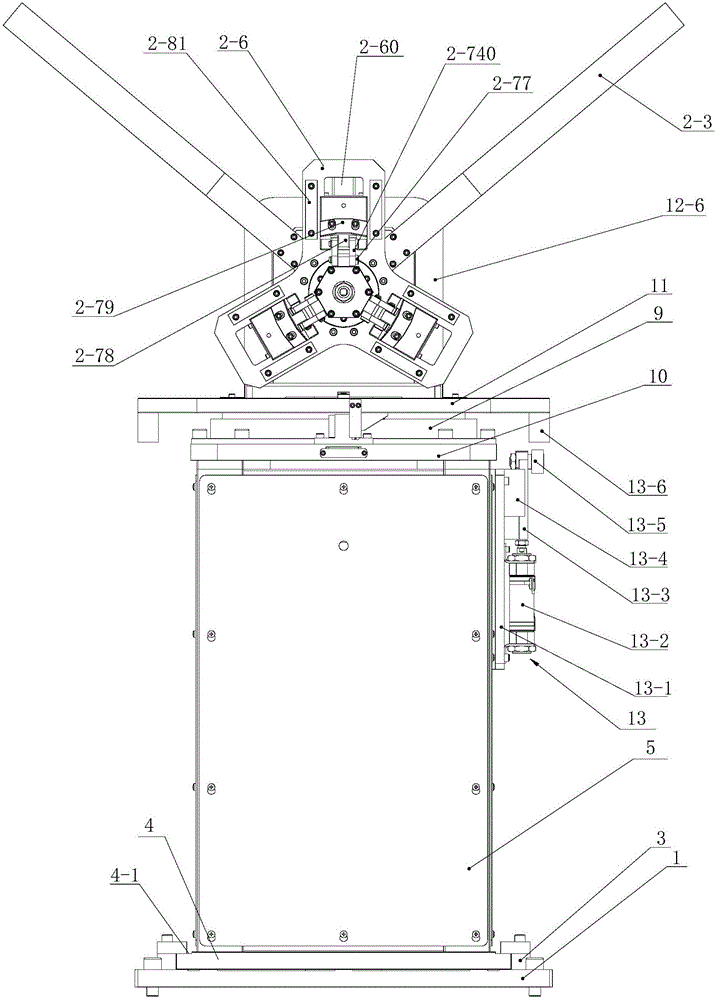

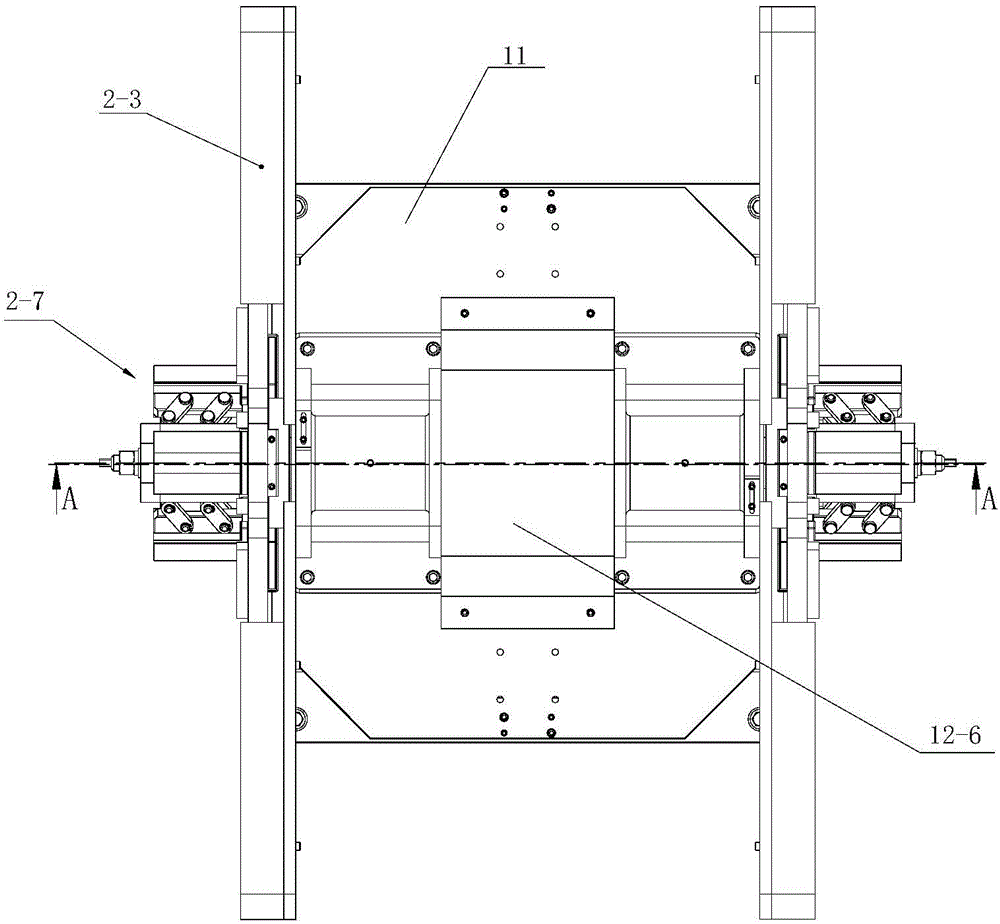

[0026] see Figure 1 to Figure 5 , a feeding device for a high-speed aluminum-finned belt rolling machine, including a base 1, a support box 5 and a tray support device 2, a center adjustment assembly is installed on the upper surface of the base, and the center adjustment assembly includes a uniformly distributed installation Four guide blocks 3 on the upper surface of the base, sliding fit between the four guide blocks is provided with a mounting plate 4, the two sides of the mounting plate are provided with a slideway 4-1 that cooperates with the guide block, the upper surface of the mounting plate A support box 5 is installed, a screw rod 6 is connected to one side of the support box, a support seat 7 is installed on the base, and a screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com