Inclined hole drilling clamp with adjustable angle

An adjustable and oblique hole technology, which is applied in the direction of the drilling mold for the workpiece, can solve the problems of high cost, long cycle, difficult manufacturing, storage and management, etc., and achieve low production cost, easy operation and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

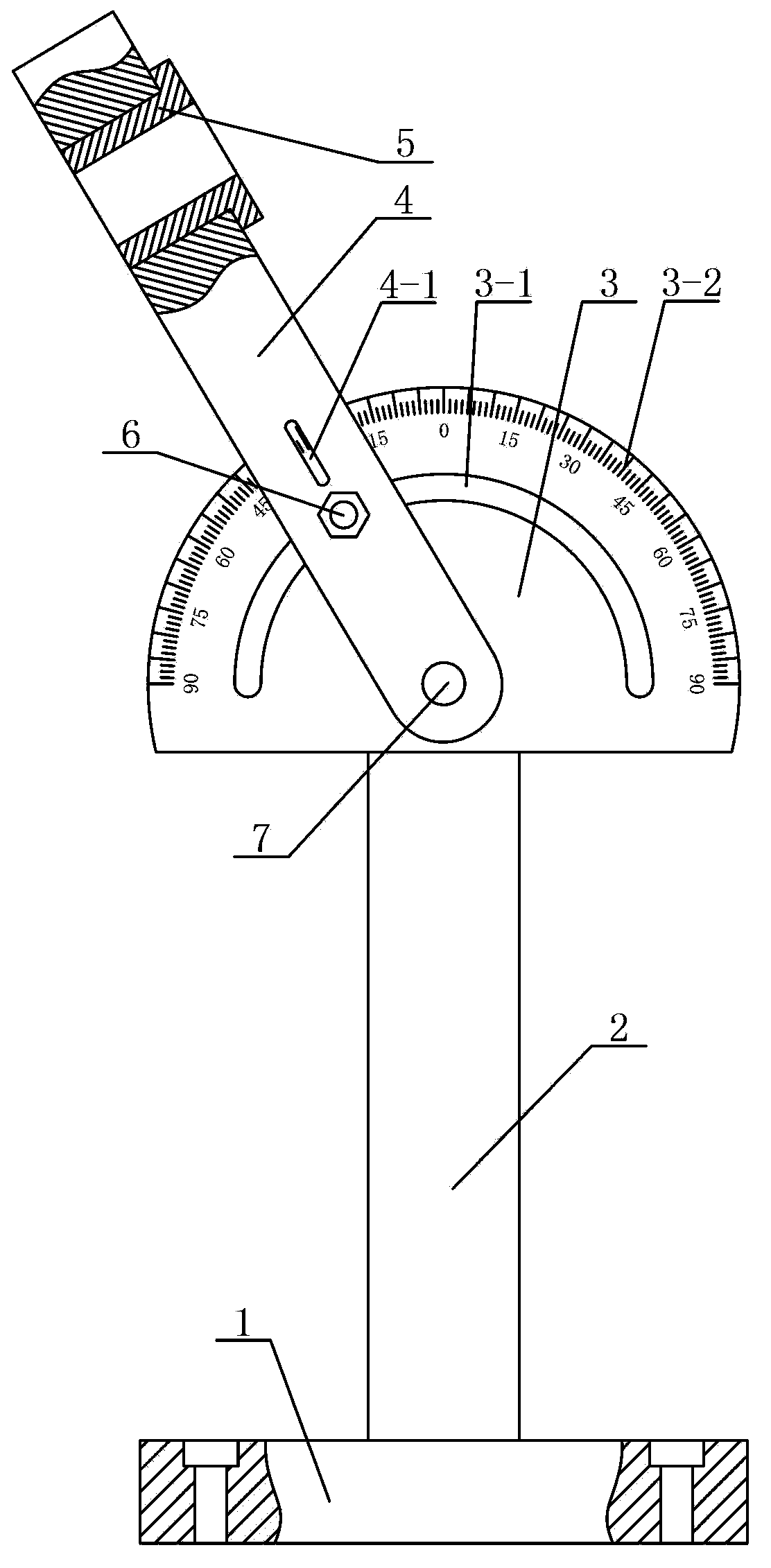

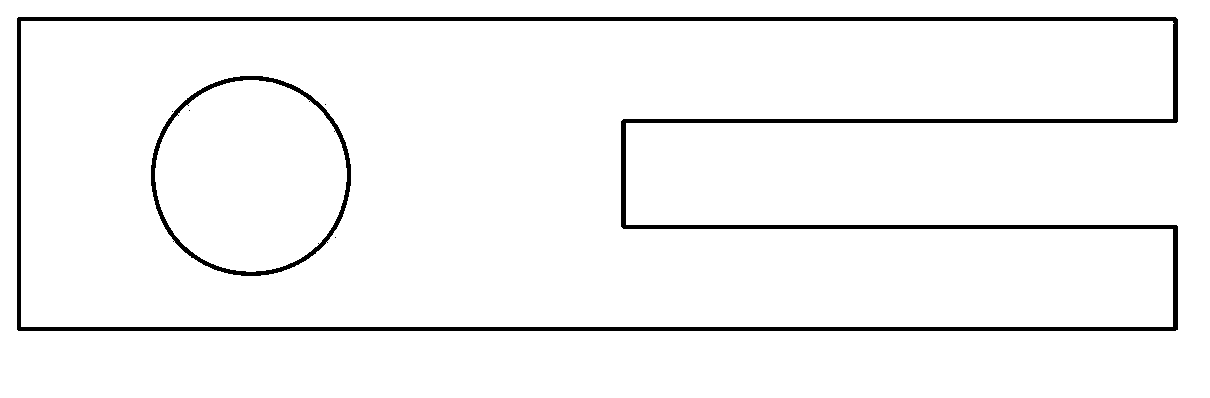

[0021] Such as Figure 1 to Figure 3 The angle-adjustable inclined hole drilling jig shown includes a base 1, a support arm 2 is provided on the upper side of the base 1, a fan-shaped guide plate 3 is provided on the upper side of the support arm 2, and the fan-shaped guide plate 3 The central position is rotationally connected with one end of the drill template 4, the other end of the drill template 4 is provided with a drill sleeve 5, and the middle part of the fan-shaped guide plate 3 is provided with an arc-shaped guide groove 3-1, and the drill template 4 passes through the arc guide The fastening bolt 6 matched with the groove 3-1 is installed on the fan-shaped guide plate 3.

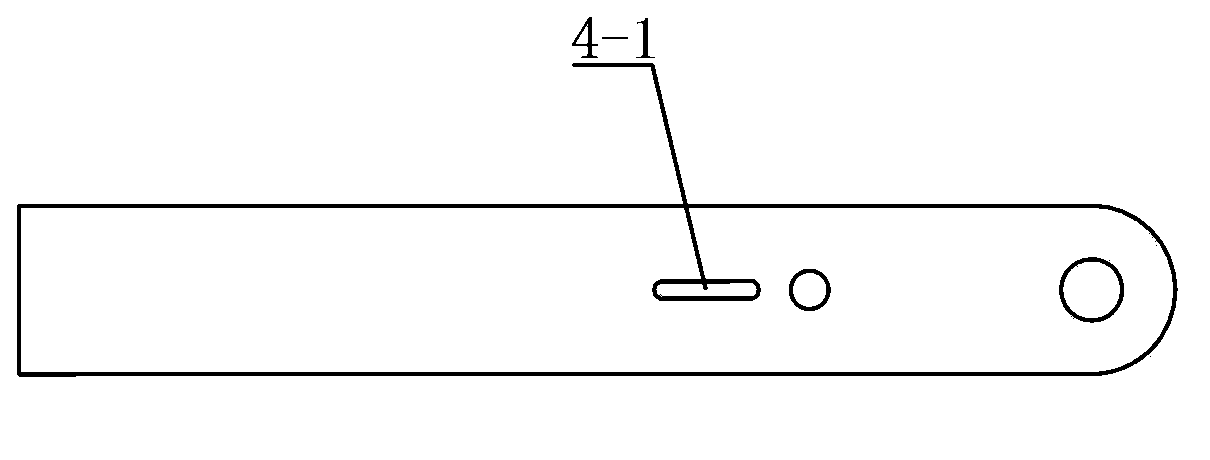

[0022] Such as figure 1 As shown, the fan-shaped guide plate 3 is provided with a scale 3-2, and the central axis position of the drilling template 4 is provided with an observation hole 4-1 for observing the scale 3-2, and the observation hole 4-1 is connected with the scale 3-2 can convenientl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com