An inverted V-type powertrain suspension device and an assembly method for its rear suspension

A technology of powertrain and rear suspension, which is applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problems of poor vibration isolation performance and occupation of bodywork space, and achieve long service life, large bodywork space, and span big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

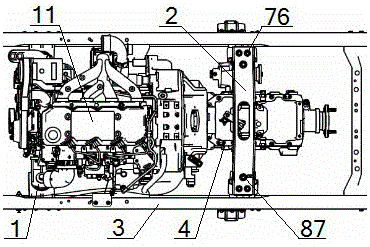

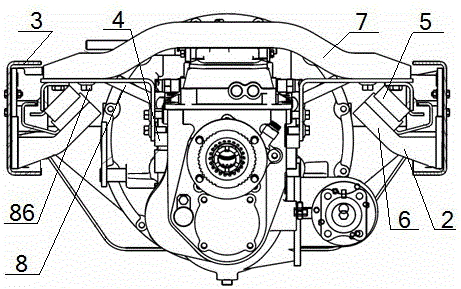

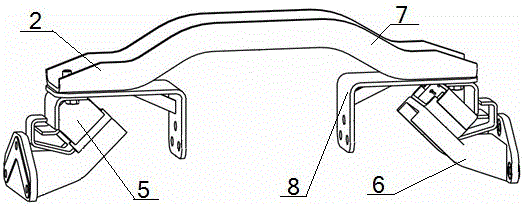

[0071] see figure 1 – Figure 9, an inverted V-shaped powertrain suspension device, including a front suspension 1 and a rear suspension 2, one end of the front suspension 1 is fixedly connected to the engine housing 11, and the other end of the front suspension 1 is connected to the frame The longitudinal beam 3 is fixedly connected, the two ends of the rear suspension 2 are fixedly connected with the frame longitudinal beam 3, and the middle part of the rear suspension 2 is fixedly connected with the middle part of the side plate 4 of the gearbox housing; the rear suspension 2 includes a block Suspension cushion assembly 5, rear suspension bracket 6 and bow-shaped beam 7, the two ends of the bow-shaped beam 7 are respectively fixedly connected with the tops of the two block-shaped suspension cushion assemblies 5, and the block-shaped suspension soft The bottom of the pad assembly 5 is fixedly connected to the frame rail 3 on the same side through the rear suspension bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com