A three-dimensional dish conveying device

A conveying device, a three-dimensional technology, applied in the field of automatic dish conveying devices, can solve the problems of large space occupation and low transmission efficiency, and achieve the effects of stable operation, reduced labor intensity, and reduced operating and placement space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

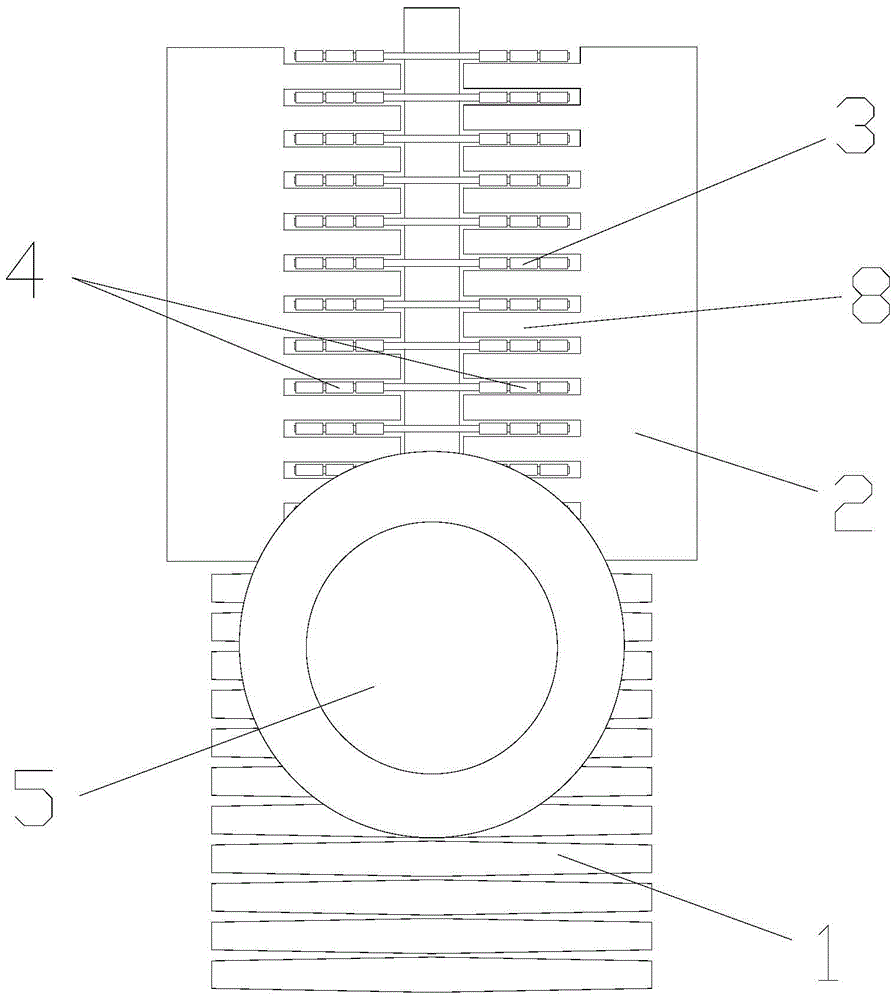

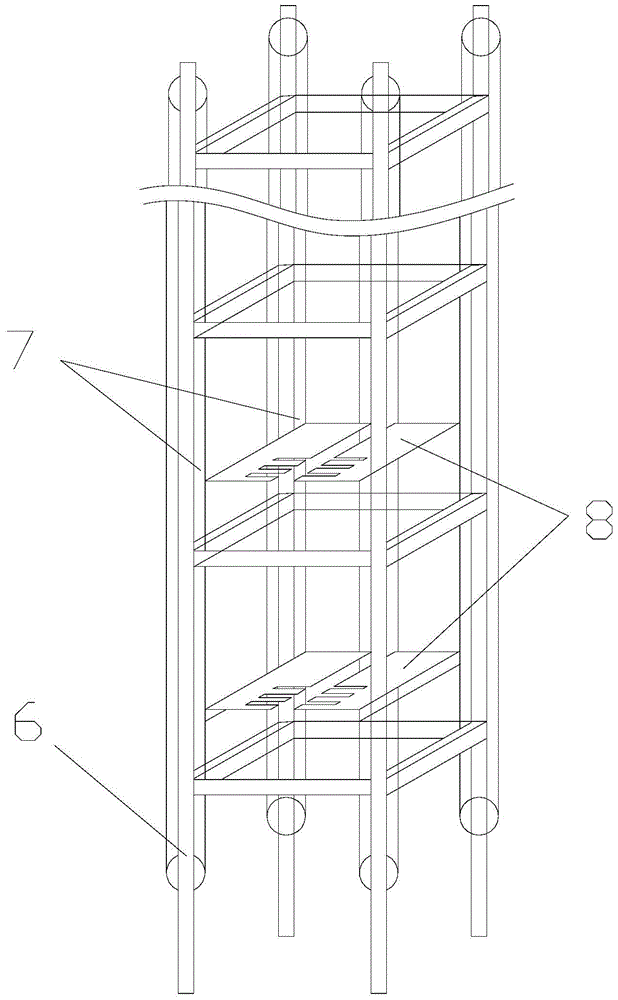

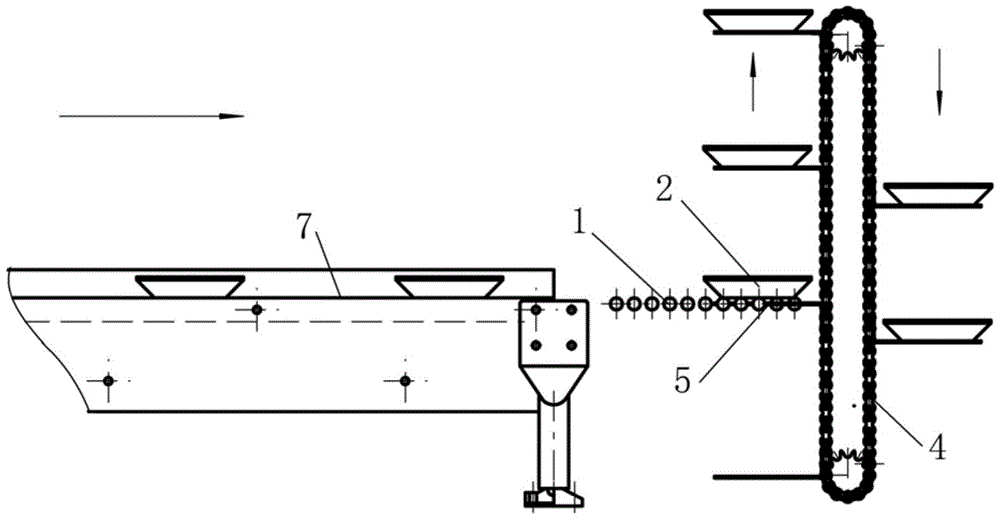

[0024] Example 1, please refer to figure 1 , 2 , 4, 5, a three-dimensional dish conveying device, comprising a horizontal conveying mechanism 1 for horizontally conveying the dinner plate, a longitudinal lifting mechanism 2 for lifting the dinner plate to a desired floor, and a vertical lifting mechanism 2 for lifting the dinner plate from The transverse transfer mechanism is transferred to the transition mechanism 3 of the longitudinal lifting mechanism.

[0025] Such as figure 1 As shown, the transition mechanism 3 includes a frame body, and a set of balls 4 symmetrically installed on both sides of the frame body, and the balls 4 are arranged at intervals along the movement direction of the transverse transmission mechanism 1. In order to make the dinner plate 5 move smoothly to the center of the transition mechanism 3 through the balls 4, the transition mechanism 3 is inclined at two heights from the food inlet to the center of the transition mechanism, and the inclination angl...

Embodiment 2

[0030] Example 2, please refer to image 3 The balls 4 are arranged at intervals along the movement direction perpendicular to the transverse transmission mechanism 1; correspondingly, a set of transmission belts 7 are provided, and a transmission plate 8 that moves synchronously with the transmission belt is installed on the transmission belt 7. The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com