Water-absorption acrylate foam material and preparation method and application thereof

An acrylate, foam material technology, applied in absorbent pads, medical science, bandages, etc., can solve the problems of easy to form agglomeration, difficult to fix in one position, uncomfortable and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

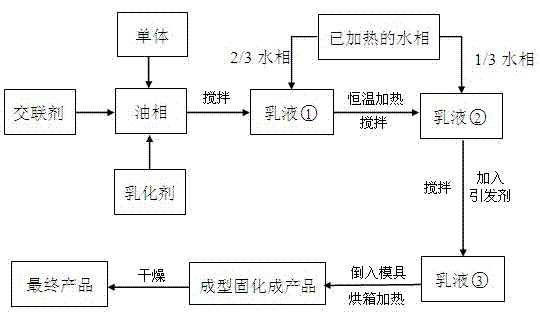

Method used

Image

Examples

Embodiment 1

[0037] 1. Preparation of water-absorbent acrylate foam

[0038] (1) To prepare the oil phase system, weigh 7.6g of isooctyl acrylate, 0.8g of isooctyl methacrylate, 4.8g of ethylene glycol dimethacrylate, 0.4g of hexanediol diacrylate, Tween-80 1.3g, stir the oil phase evenly and set aside.

[0039] (2) Prepare the water phase system, weigh 17.71g of calcium chloride, add water to 460g to dissolve, and set aside.

[0040] (3) To prepare the initiator phase, weigh 1.71g of ammonium persulfate, add water to 10g to dissolve it, and set aside.

[0041] (4) Transfer 300g of the prepared water phase into a 1000ml three-necked flask, start stirring, raise the temperature to 75°C, and keep the stirring speed above 800 rpm, then add the evenly stirred oil phase into the three-necked flask until the emulsion becomes viscous Add 160g of the water phase to the flask dropwise, and finally add the initiator phase to the flask. After polymerization, pour the mixture into a large polytetraf...

Embodiment 2

[0045] 1. Preparation of water-absorbent acrylate foam

[0046](1) To prepare an oil phase system, weigh 16.4g of isodecyl acrylate, 4.0g of dipropylene glycol dimethacrylate, 0.8g of triethylene glycol diacrylate, 2.0g of diglycerol monoisostearate, and Mix well and set aside.

[0047] (2) Prepare the water phase system, weigh 36.31g of calcium nitrate, add water to 480g to dissolve it, and set aside.

[0048] (3) Prepare the initiator phase, weigh 2.11g of sodium persulfate, add water to 10g to dissolve, and set aside.

[0049] (4) Transfer 320g of the prepared water phase into a 1000ml three-necked flask, start stirring, raise the temperature to 60°C, and stir at a speed above 800 rpm, then add the evenly stirred oil phase into the three-necked flask until the emulsion becomes viscous Add 160g of the water phase to the flask dropwise, and finally add the initiator phase to the flask. After the polymerization reaction, pour the mixture into a large polytetrafluoroethylene ...

Embodiment 3

[0053] 1. Preparation of water-absorbent acrylate foam

[0054] (1) Prepare the oil phase system, weigh 4.9g of octadecyl acrylate, 5.0g of isodecyl methacrylate, 8.6g of dipropylene glycol diacrylate, and 3.1g of Tween-20, stir the oil phase evenly and set aside .

[0055] (2) Prepare the water phase system, weigh 16.31g of potassium borate, add water to 480g to dissolve it, and set aside.

[0056] (3) Prepare the initiator phase, weigh 1.37g of potassium persulfate, add water to 10g to dissolve it, and set aside.

[0057] (4) Transfer 320g of the prepared water phase into a 1000ml three-necked flask, start stirring, raise the temperature to 80°C, and keep the stirring speed above 800 rpm, then add the evenly stirred oil phase into the three-necked flask until the emulsion becomes viscous Add 160g of the water phase to the flask dropwise, and finally add the initiator phase to the flask. After the polymerization reaction, pour the mixed solution into a large polytetrafluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell size | aaaaa | aaaaa |

| Average deionized water absorption rate | aaaaa | aaaaa |

| Average salt water absorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com