Box-shaped steel pier with embedded energy consumption shell plates

A steel bridge pier and box-shaped technology, applied in the field of steel bridge piers, can solve the problems of difficulty in damage detection and reinforcement of steel bridge piers, deterioration of seismic performance of box-shaped steel bridge piers, and easy tearing of corners of box-shaped steel bridge piers. The effect of shortening traffic control time, excellent seismic performance and strong deformation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

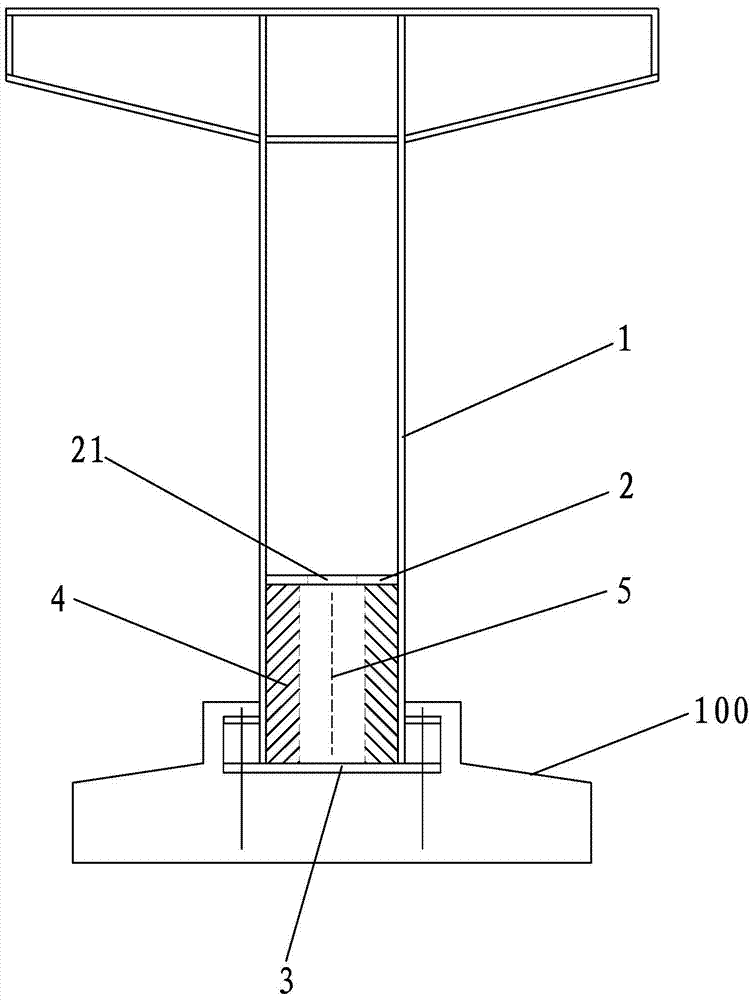

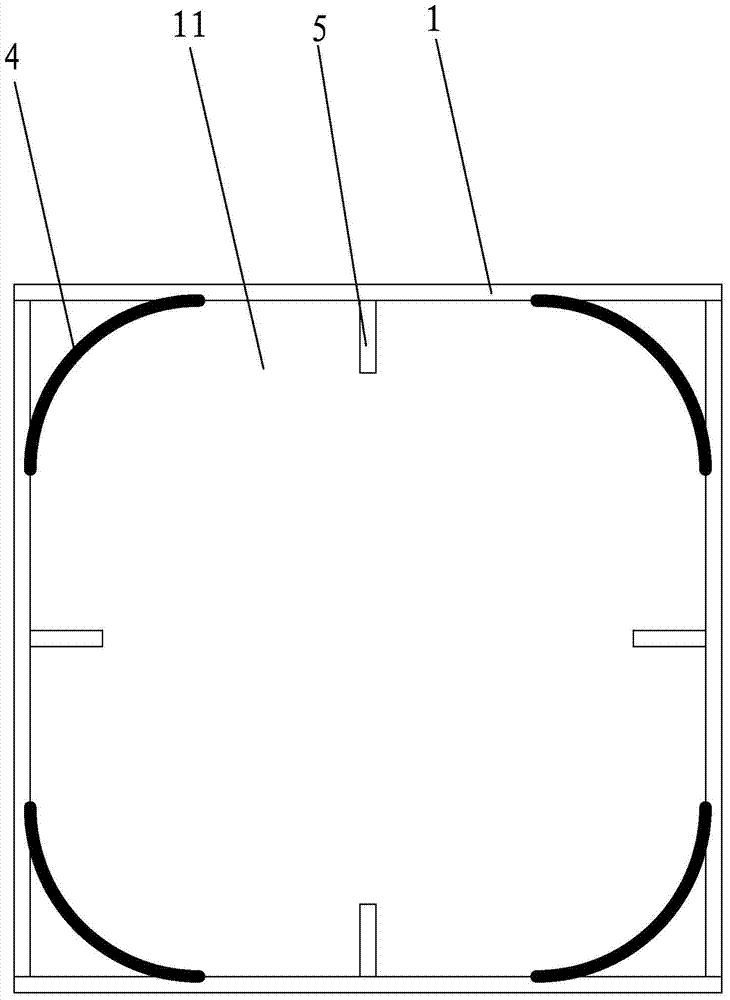

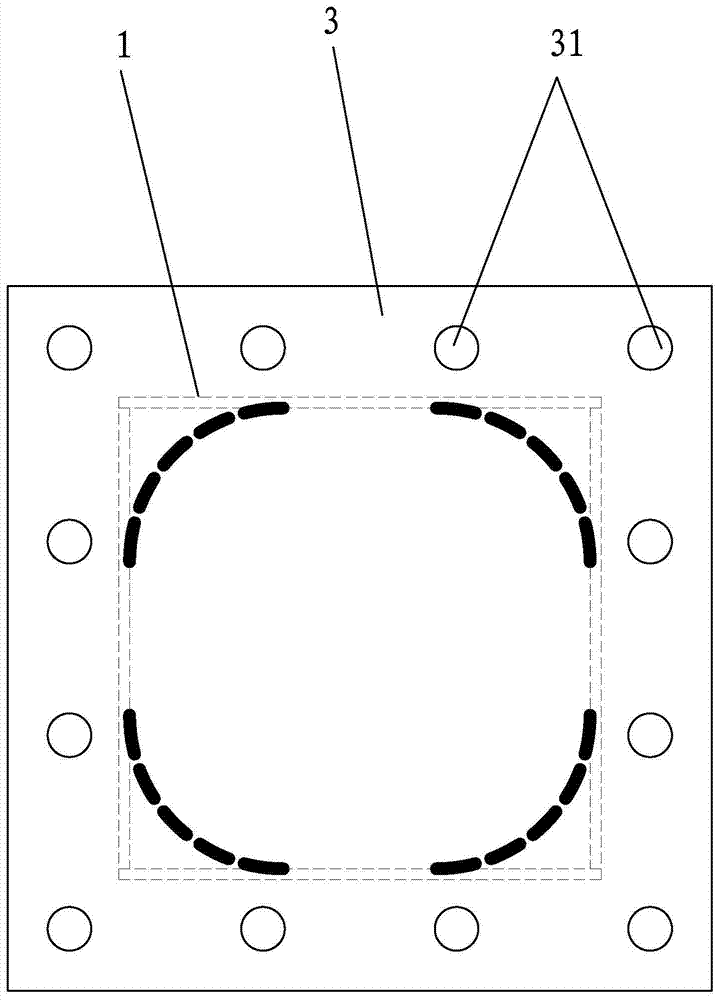

[0027] The box-shaped steel bridge pier with embedded energy-dissipating shell plate of the present invention, such as Figure 1-3 As shown, it includes a box-shaped steel pier body 1, a transverse diaphragm 2 and a bottom plate 3. The lower part of the box-shaped steel pier body 1 has a root compartment 11, and the height of the root compartment 11 is the transverse height of the box-shaped steel pier body. 1.0 to 1.5 times the cross-sectional area, the diaphragm 2 is welded and fixed in the lower part of the box-shaped steel pier body 1, and the middle part of the diaphragm 2 is provided with a central through hole 21 communicating with the root compartment 11. The bottom plate 3. The cover is set outside the lower end of the box-shaped steel pier body 1, and is welded together with the box-shaped steel pier body 1. The space between the box-shaped steel pier body 1 located between the diaphragm 2 and the bottom plate 3 is as described The root compartment 11, the four corne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com