Explosion venting plate and preparation method thereof

An explosion venting plate and explosion venting technology, which is applied in the direction of buildings and building structures, can solve the problems of the explosion venting plate detachment, the explosion venting plate has no load-bearing function, etc., and achieve the effect of large explosion venting function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

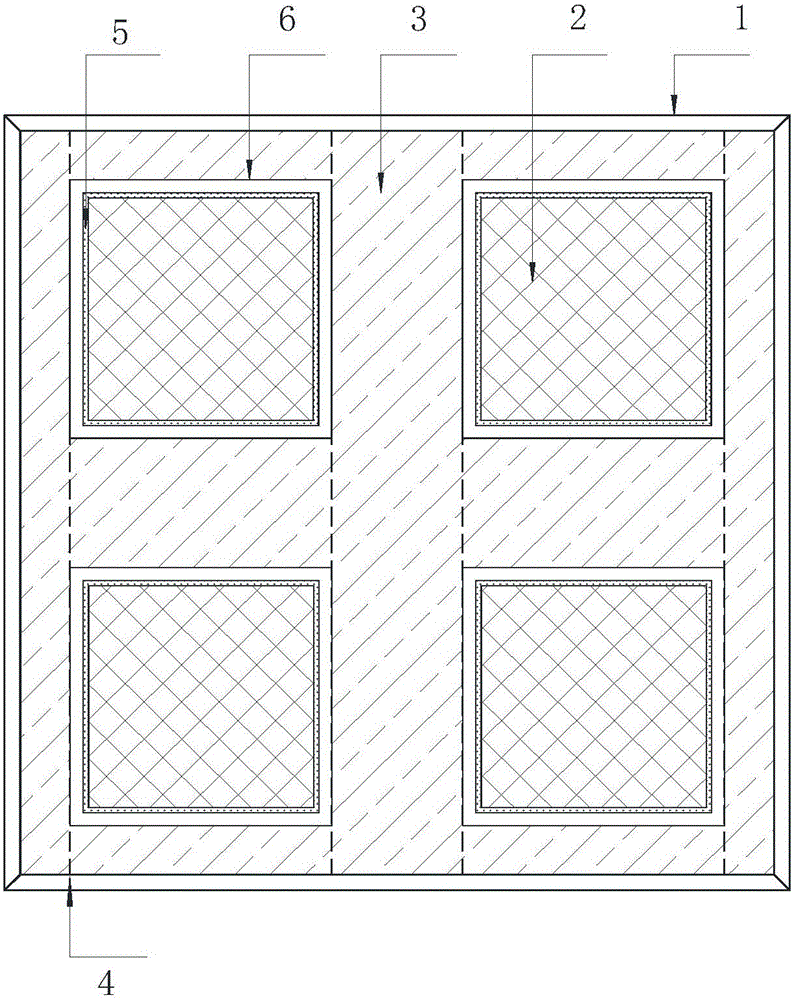

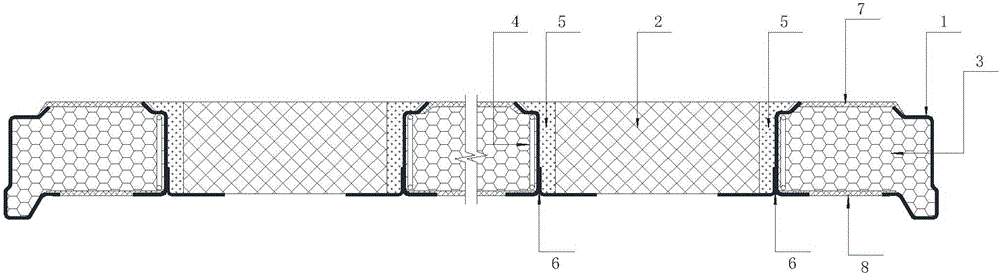

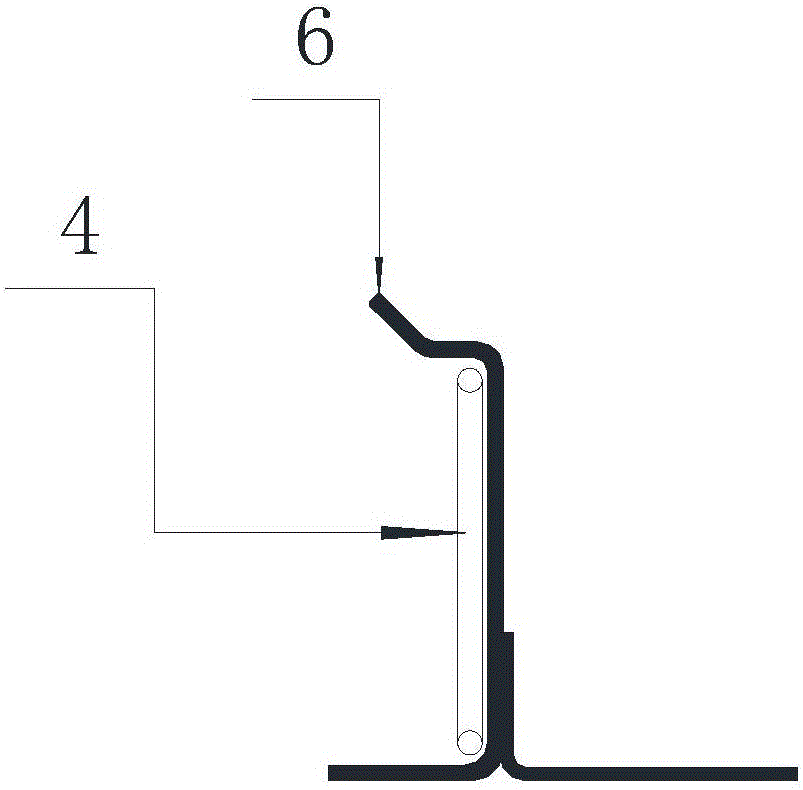

[0038] The explosion venting plate described in this embodiment, such as figure 1 with figure 2As shown, it includes a main body layer, an explosion-venting layer, an outer frame, an inner frame, an intermediate structure, and a flexible caulking material filled between the explosion-venting layer and the inner frame. The main body layer is divided into the upper layer of the main body layer, the middle layer of the main body layer and the lower layer of the main body layer. The main body layer is a foamed cement layer 3, and holes are opened on the foamed cement layer 3. The foamed cement layer The upper layer 7 is a cement layer containing glass fiber mesh; the middle layer of the foamed cement layer 3 is an insulating core layer, specifically a foamed cement core layer; the lower layer 8 of the foamed cement layer is a layer containing glass fiber mesh and cooling Brushed cement layer. The lower layer 8 of the foamed cement layer contains glass fiber mesh and cold-drawn ...

Embodiment 2

[0049] The difference between the explosion venting panel described in this embodiment and the explosion venting panel described in Example 1 is that the upper layer of the explosion venting layer and the upper layer of the main body layer are prepared as a whole and then cut to form two parts. The preparation method of the explosion venting plate described in this embodiment comprises the following steps:

[0050] Step 1: First use an electric welding machine to weld the external steel enclosure 1 and the internal truss 4 into shape, then weld the C-shaped steel and L-shaped steel to form the internal steel enclosure 6, and then weld the internal steel enclosure 6 to the internal truss 4 Afterwards, the whole is put into the external steel enclosure 1 and welded with the external steel enclosure 1;

[0051] Step 2: First spread the cement slurry in the lower layer containing glass fiber mesh and cold-drawn wire between the external steel frame 1 and the built-in steel frame 6...

Embodiment 3

[0059] The difference between the explosion venting panel described in this embodiment and the explosion venting panel described in Example 1 is that the explosion venting layer is a double-sided composite steel plate layer of a polystyrene board, and the double-sided composite steel plate layer of a polystyrene board is For purchased products, since the double-sided composite steel plate of polystyrene board already has anti-crack effect, there is no need to add other anti-crack materials.

[0060] The preparation method of the explosion-venting plate described in the present embodiment comprises the following steps:

[0061] Step 1: First use an electric welding machine to weld the external steel enclosure 1 and the internal truss 4 into shape, then weld the C-shaped steel and L-shaped steel to form the internal steel enclosure 6, and then weld the internal steel enclosure 6 to the internal truss 4 Afterwards, the whole is put into the external steel frame 1 and welded with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com