Construction method for right-angle skew tunnel-entering cover arch of unsymmetrical-loaded and shallow-buried tunnel

A technology of oblique normal construction and shallow buried tunnels, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of no operating platform, large amount of cut and excavated earth and rocks, and narrow entry positions, so as to reduce mountain cutting. The amount of excavated earth and rocks, the construction period is short, and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

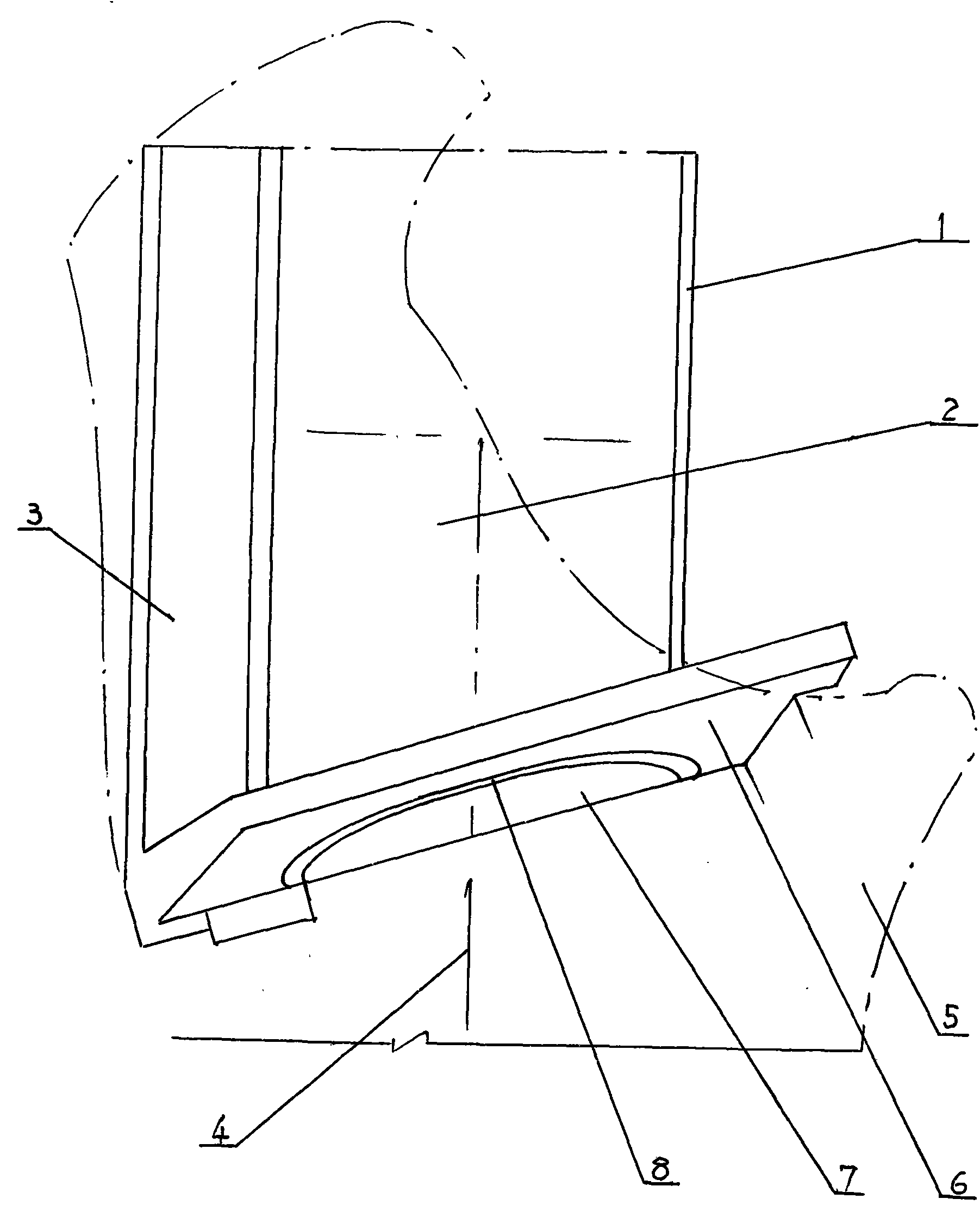

[0023] Such as Figures 1 to 3 As shown, a construction method for an oblique normal bias pressure shallow buried tunnel entry arch, including the following steps:

[0024] (1), according to the angle between the mountain body 5 and the longitudinal oblique cut of the tunnel, the tunnel entry mountain section formed after the mountain body cutting and excavation is determined. 45°~60°. Obviously, it can also be determined according to the angle between the mountain body and the advancing direction of the tunnel.

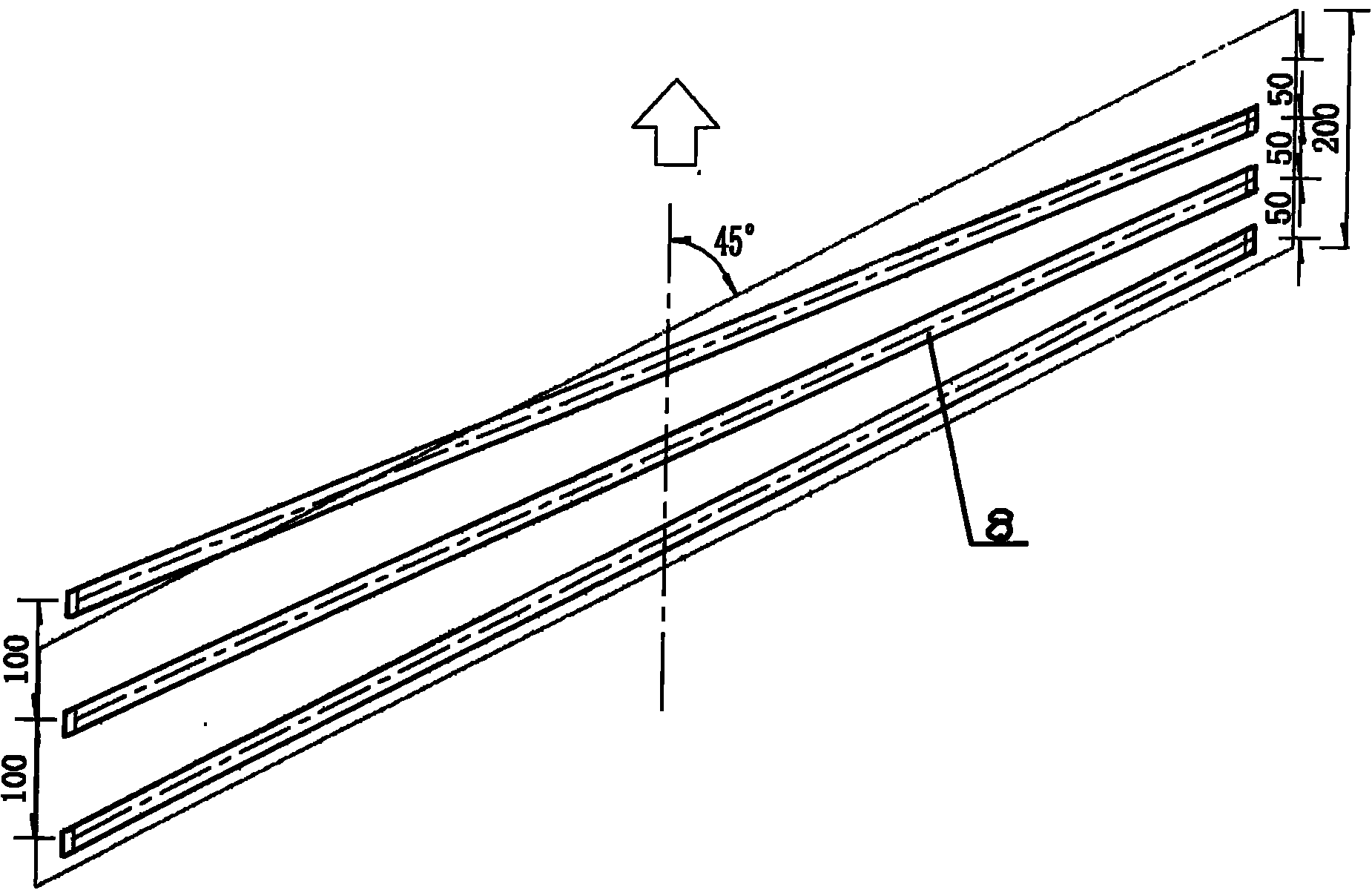

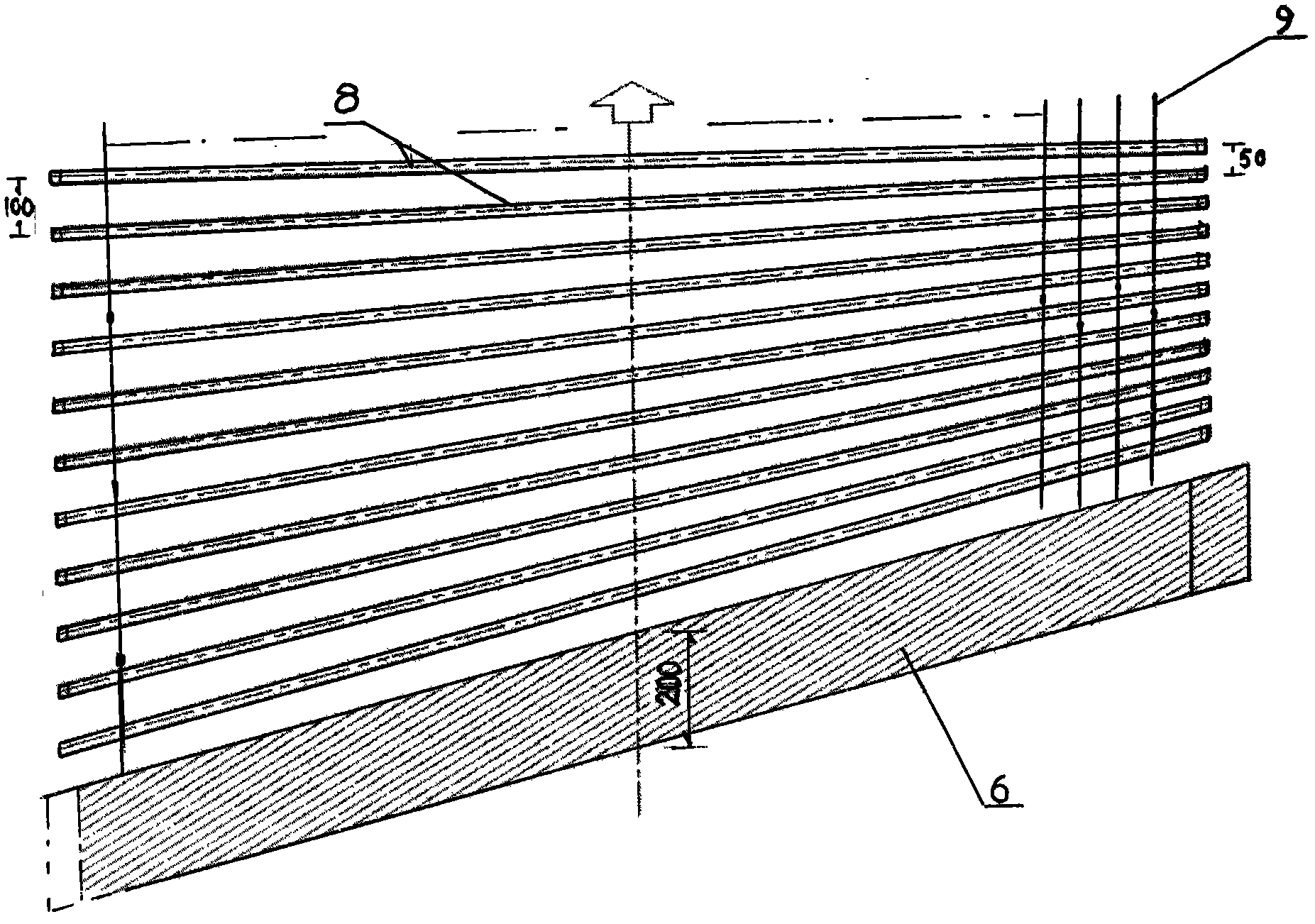

[0025] (2), according to the oblique angle between the tunnel entrance mountain section and the driving axis line of the tunnel, a steel arch frame 8 supporting the arch is set up in front of the tunnel entrance mountain section, and the erection direction of the steel arch frame is in line with the tunnel driving axis line. Installed obliquely at an angle of 45° to 60°, the steel arches on the left end and the steel arches on the right end are misplaced, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com