Rod body sealing structure

A technology of sealing structure and rod body, which is applied in the direction of fluid pressure actuating device, etc., can solve problems such as hydraulic cylinder shaking and crawling, customer economic loss, guide sleeve sealing failure, etc., and achieves simple sealing configuration structure, wide application conditions and sealing effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

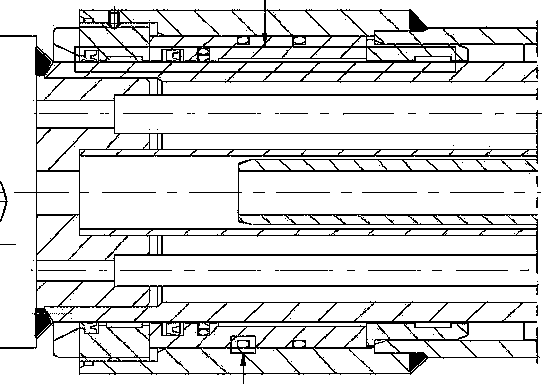

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0010] like figure 1 As shown, the hydraulic cylinder piston rod sealing structure of the present invention is to install a sealing device between the guide sleeve and the piston rod, that is, on the outer cylindrical surface of the piston rod. The sealing device is composed of the main LBH support ring, the F4 bronze support ring and the shaft. Composed of Y ring + retaining ring, step seal, oil-free bearing, and F4 bronze support ring. When the Y-ring is installed, the end face of the lip should face the side with high hydraulic pressure. When the pressure changes greatly and the sliding speed is high, the support ring should be used to fix the sealing ring. In the dynamic seal, when the pressure is greater than 20MPa, the Y-ring will be squeezed into the gap and damaged, so it is necessary to set a back-up ring made of PTFE or nylon on the low-pressure side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com