Piston sealing structure

A technology of sealing structure and piston, which is applied in the direction of fluid pressure actuating device, etc., can solve the problems of large impact, economic loss of customers, and failure of the whole machine to achieve simple sealing structure, wide application conditions and good sealing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

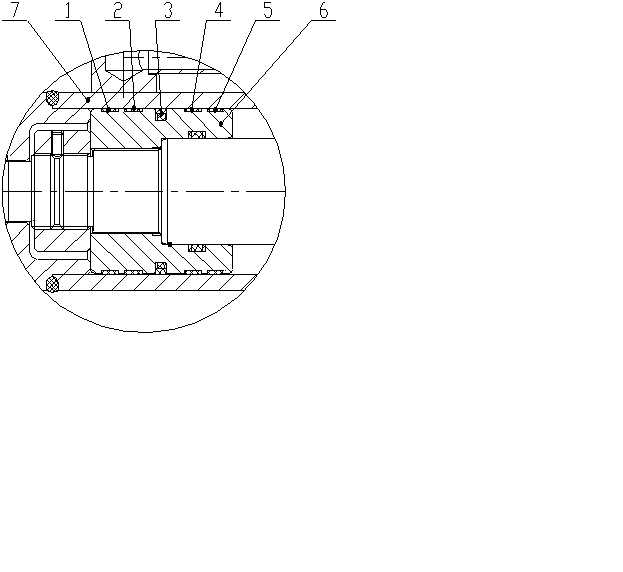

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0011] Such as figure 1 Shown, the sealing structure of hydraulic cylinder piston of the present invention is to install sealing device between piston 6 and cylinder barrel 7, promptly on the outer cylindrical surface of piston, and this sealing device is mainly made of support ring 1,5, dirt receiving ring 2, 4. Gray ring 5, piston 6 and cylinder 7 are formed. The support rings 1 and 5 are made of CM20 material, which is a reinforced aromatic polyacrylic phenolic resin braided composite material with graphite additives. The material has strong thermal stability and wear resistance, low friction coefficient, and can withstand extreme conditions. Large lateral force; the anti-pollution rings 2 and 4 adopt the design of KZT, which uses the soft KZT material of the anti-pollution rings to absorb impurities generated during the operation of the hydraulic cylinder to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com