Automobile sliding door test bench

A test bench, sliding door technology, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as smoothness, door opening and closing force limit force, and durability without guidance. Achieve the effect of shortening the R&D cycle, low cost, and high verification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

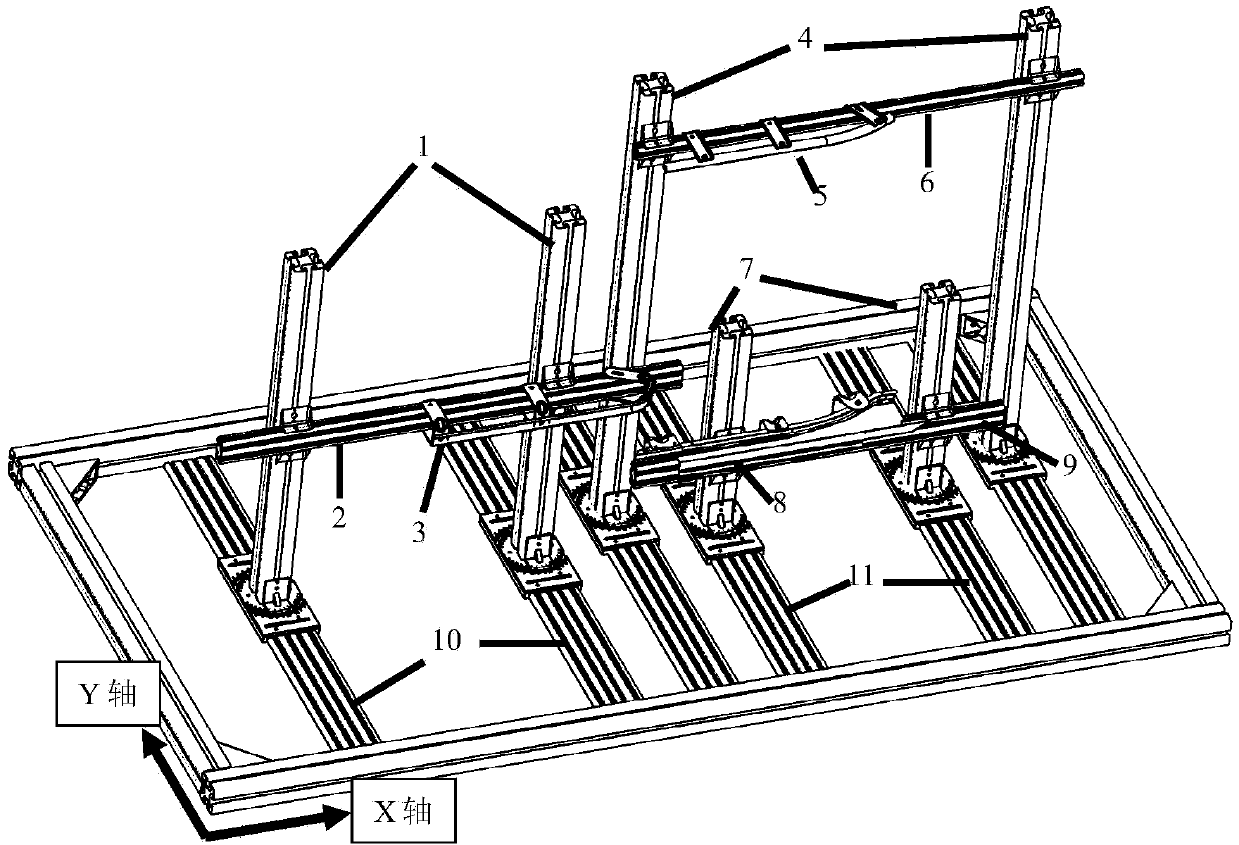

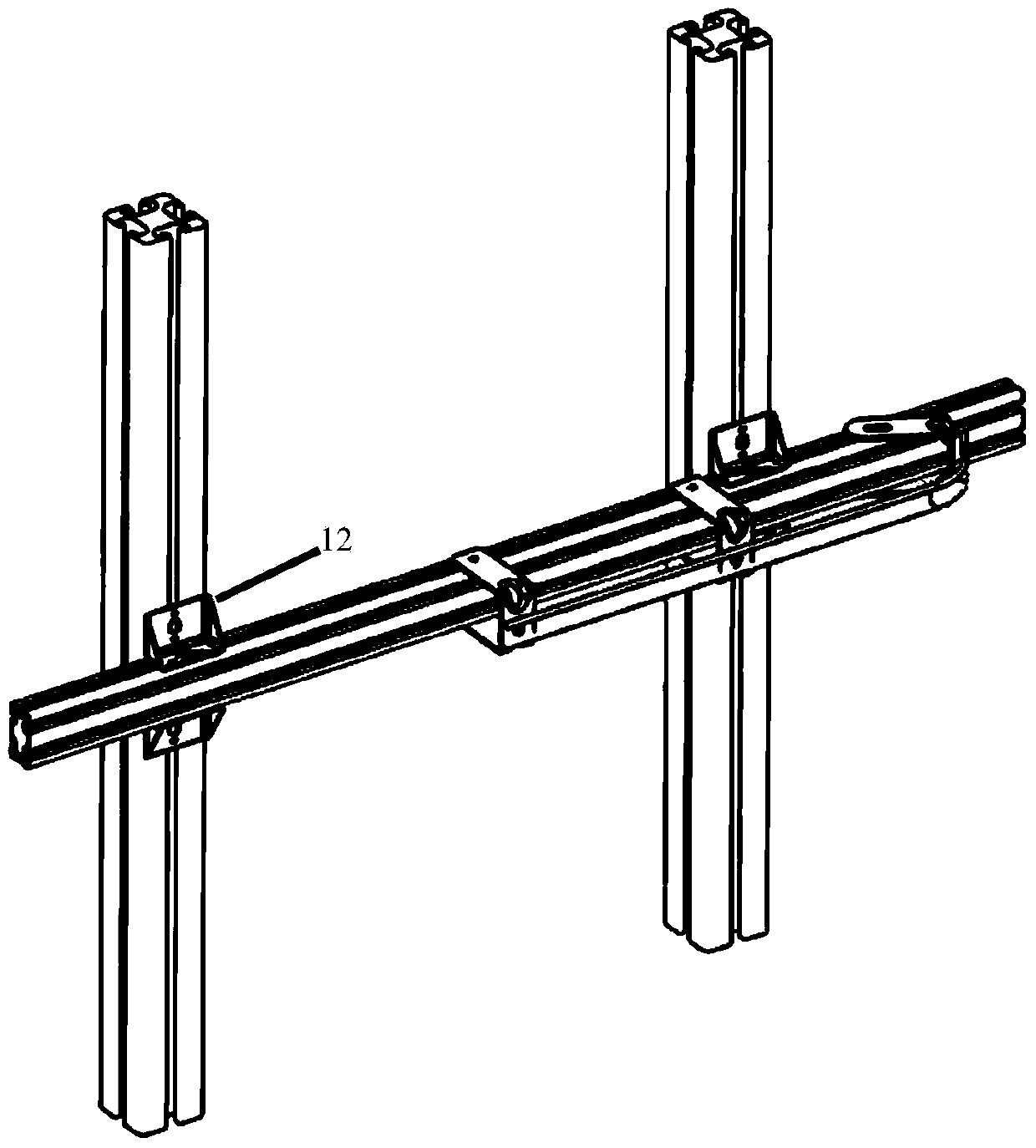

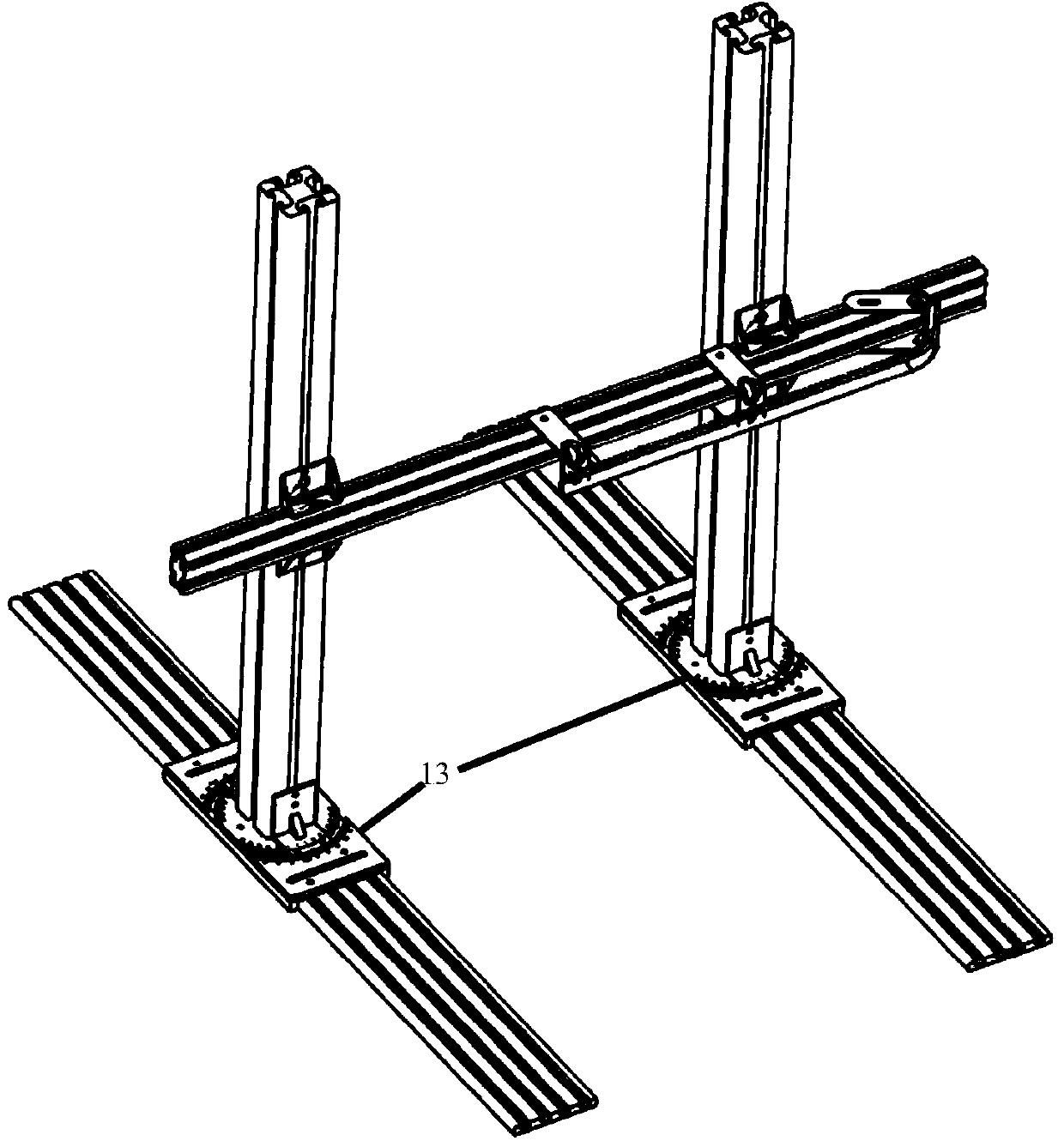

[0027] The following will be combined with Figure 1-3 The technical solution of the present invention is described in detail.

[0028] like figure 1 As shown, the X axis and the Y axis represent the coordinate directions of the vehicle coordinate system.

[0029] The automobile sliding door platform according to the present invention includes: a middle guide rail installation column 1, a middle guide rail installation crossbar 2, a sliding door middle guide rail 3, an upper guide rail installation column 4, an upper guide rail 5, and an upper guide rail installation crossbar 6 , lower guide rail installation column 7, lower guide rail 8, lower guide rail installation cross bar 9, first slide rail 10, second slide rail 11, cross bar installation triangular plate 12, column installation rotary compass 13 and guide rail connecting bracket 14;

[0030] Among them, the upper guide rail 5, the middle guide rail 3 and the lower guide rail 8 of the sliding door are respectively ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com