Checking platform with integral revolving and lifting function

An integrated, platform-based technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of product quality prone to bumps, work efficiency, small equipment space, and low work efficiency, achieving short inspection cycles, The effect of compact equipment and lightening work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

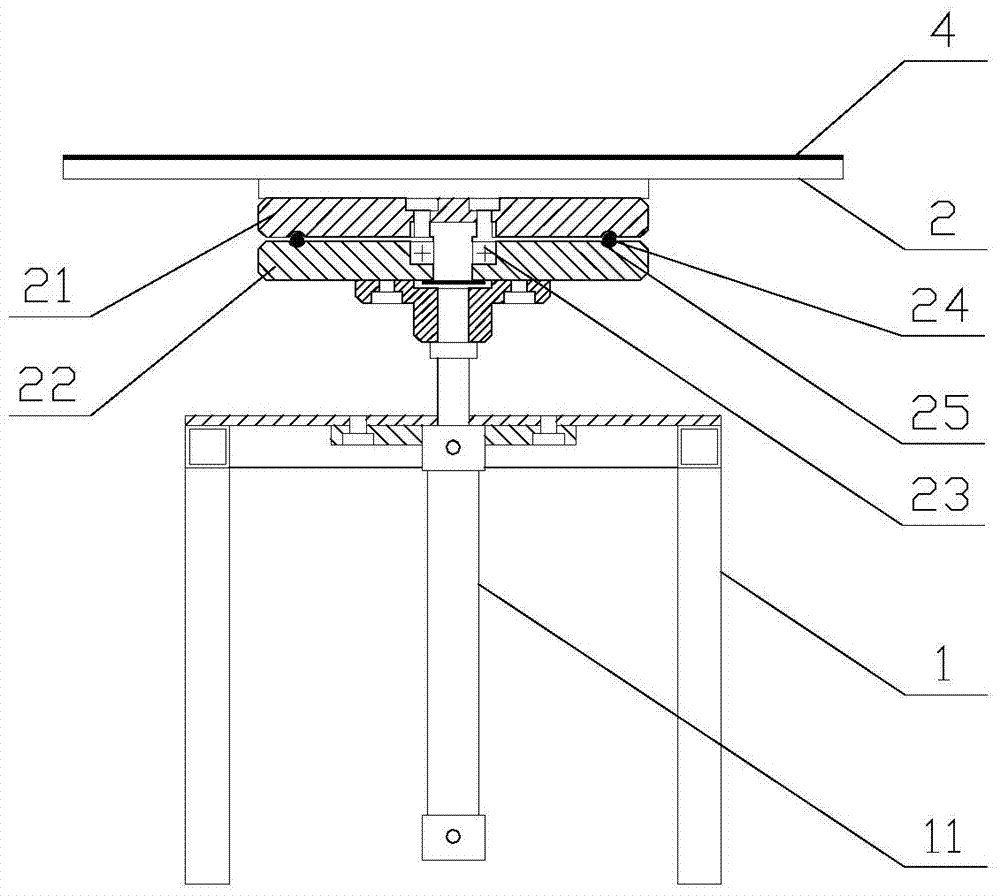

[0019] Embodiment 1: The inspection platform with integrated rotary and lifting functions in this embodiment 1 is used for the cylinder head appearance inspection on the engine cylinder head machining production line, such as figure 1 As shown, the inspection platform includes a frame 1, a turntable 2 installed above the frame, and a lifting mechanism and a slewing mechanism arranged on the frame for lifting and rotating the turntable. The lifting mechanism includes a lifting cylinder vertically arranged on the frame. 11. The piston rod of the lifting cylinder passes through the surface of the frame and is fixed to the turntable. The turntable can move up and down under the action of the piston rod of the cylinder. When the piston rod is stretched to the highest position, the surface of the turntable is at the same height as the production line , the cylinder head to be inspected can be translated from the production line to the rotary table for inspection. The lifting cylinder...

Embodiment 2

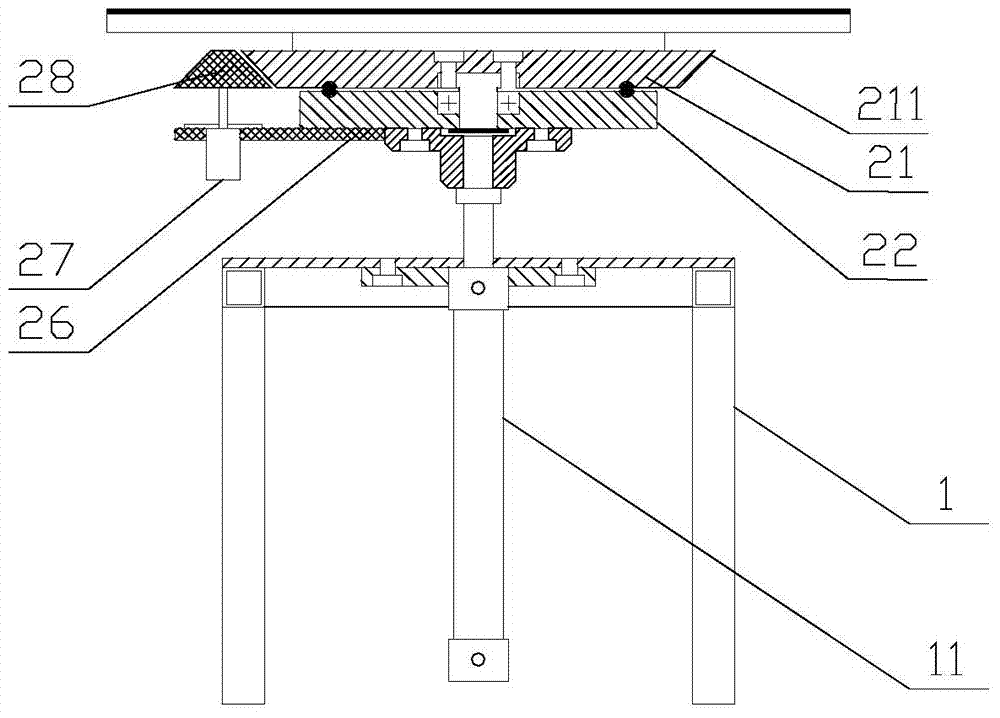

[0021] Embodiment 2: The inspection platform with integrated rotary and lifting functions in this embodiment 2 is used for the cylinder head appearance inspection on the engine cylinder head machining production line, such as figure 2 As shown, the side edge of the upper plate of the rotary mechanism in the present embodiment 2 is designed with helical teeth 211, the motor frame 26 is installed on the lower plate, the rotary motor 27 is installed on the motor frame, and the output shaft end of the rotary motor is sleeved with a horizontal The bevel gear 28, the horizontal bevel gear and the helical gear mesh with each other to form power transmission. When the rotary disc needs to rotate, the rotary motor can be started, so that the horizontal bevel gear on the output shaft of the rotary motor drives the helical gear and then drives the upper plate and the bevel gear. The turntable rotates so that inspectors can fully concentrate on observing the appearance of the cylinder hea...

Embodiment 3

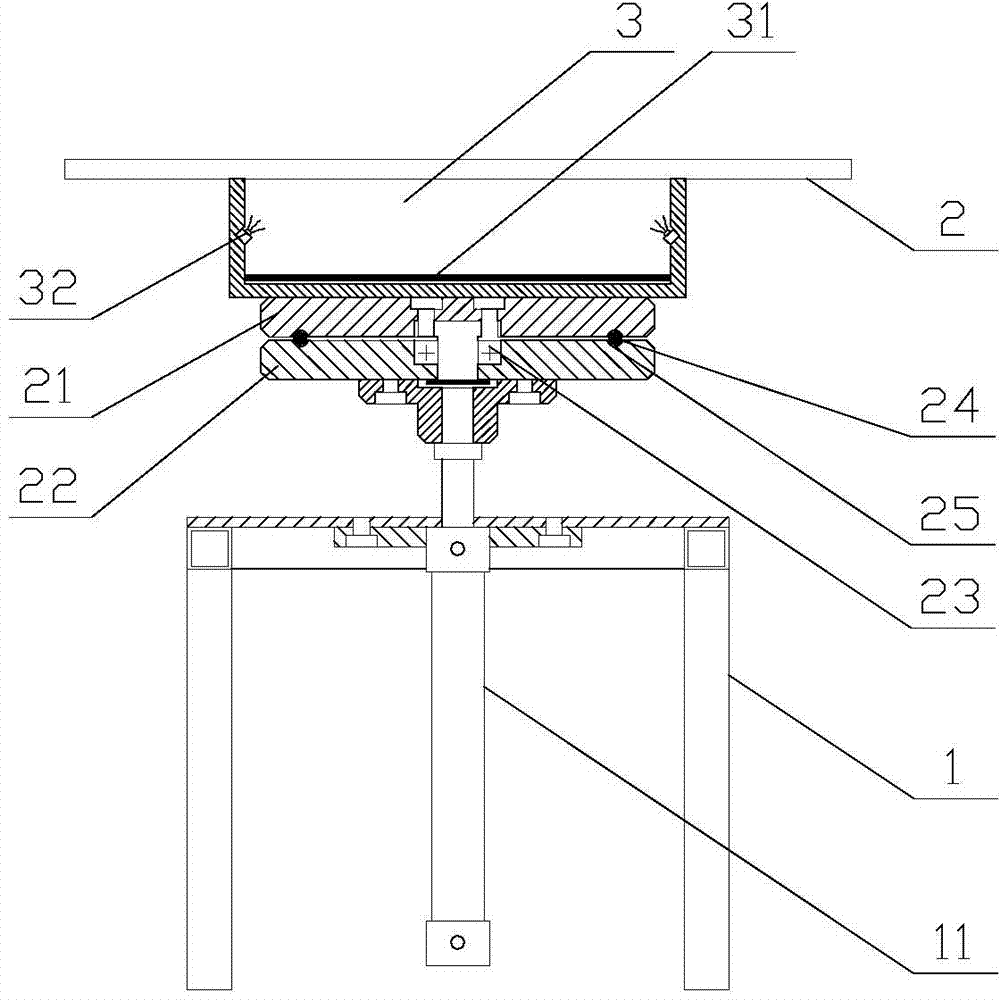

[0022] Embodiment 3: The inspection platform with integrated rotary and lifting functions in this embodiment 3 is used for the cylinder head appearance inspection on the engine cylinder head machining production line, such as image 3 As shown, the lower part of the rotary disk of the present embodiment 3 is designed with an observation chamber 3 with a top opening. The top of the observation chamber is attached to the bottom surface of the rotary disk and connected with the rotary disk. The opening of the observation chamber is larger than the bottom surface of the cylinder head. A plane mirror 31 is installed on the inner bottom surface of the observation chamber. Of course, a convex mirror can also be used, and the observation range is larger. The surface of the rotating disk corresponding to the top opening of the observation chamber is transparent. When the cylinder head is placed on the surface of the rotating disk for inspection, the inspection Personnel can indirectly o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com