Centrifugal-temperature composite test box

A composite test and test chamber technology, which is applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, and measuring devices, etc. It can solve the problem that the accuracy of the temperature environment cannot meet the calibration requirements and cannot achieve centrifugation Machine and other problems, to achieve the effect of solving the uneven temperature of the gas, facilitating experimental installation and transportation, and high heating and cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

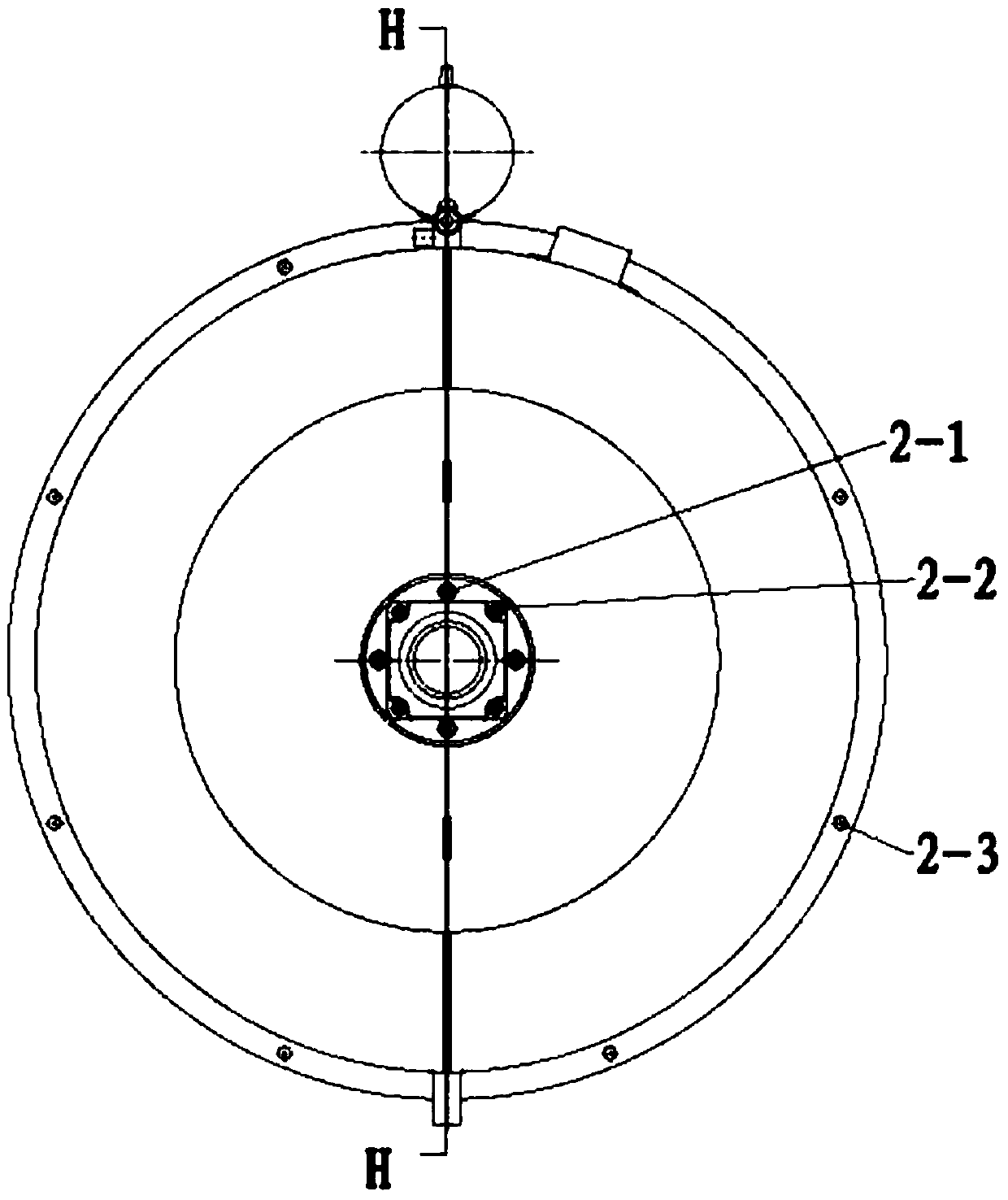

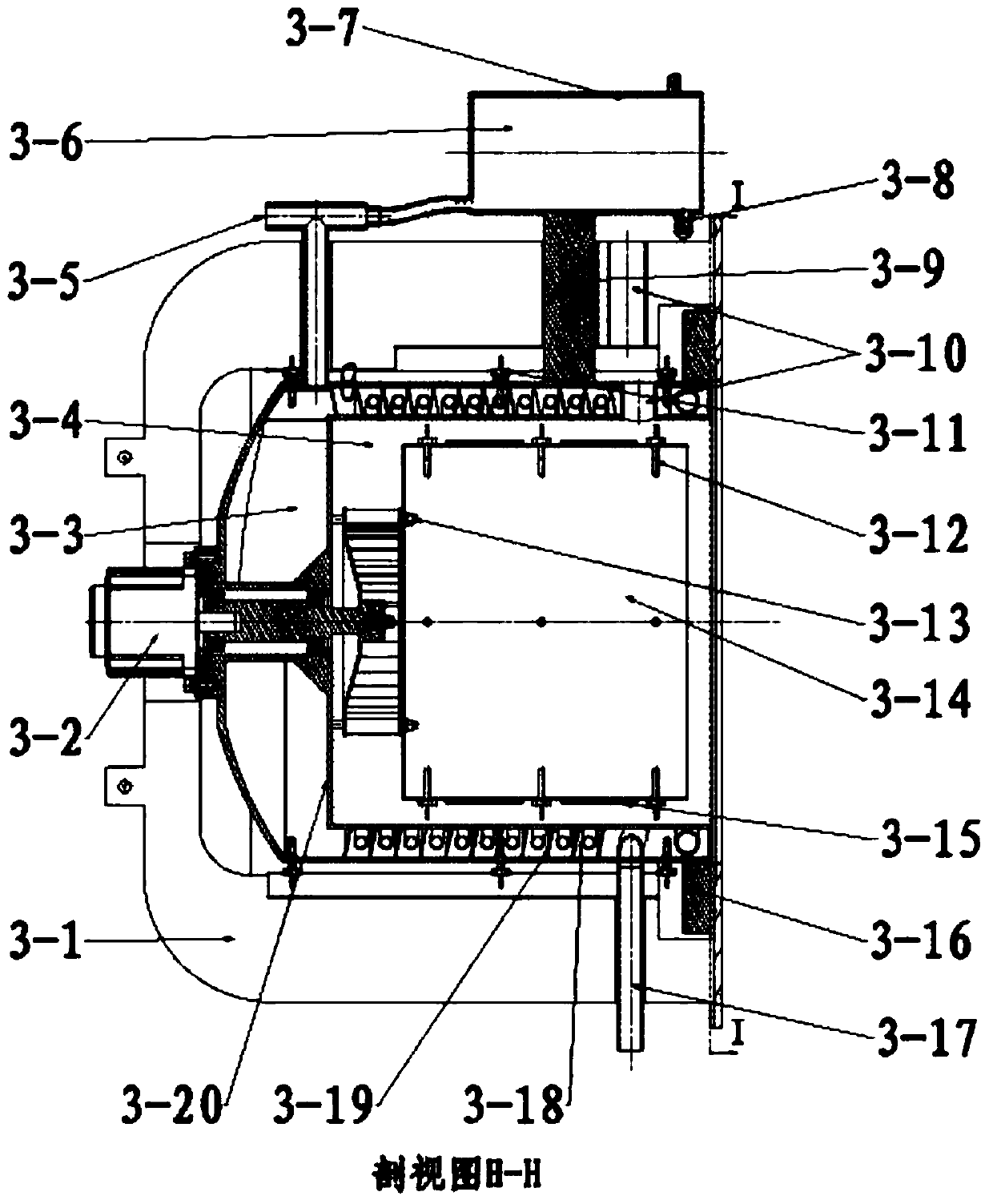

[0025] The invention is a centrifugal-temperature composite test box, which is mainly composed of a main body part of the box, an expansion chamber and a gas circulation system.

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

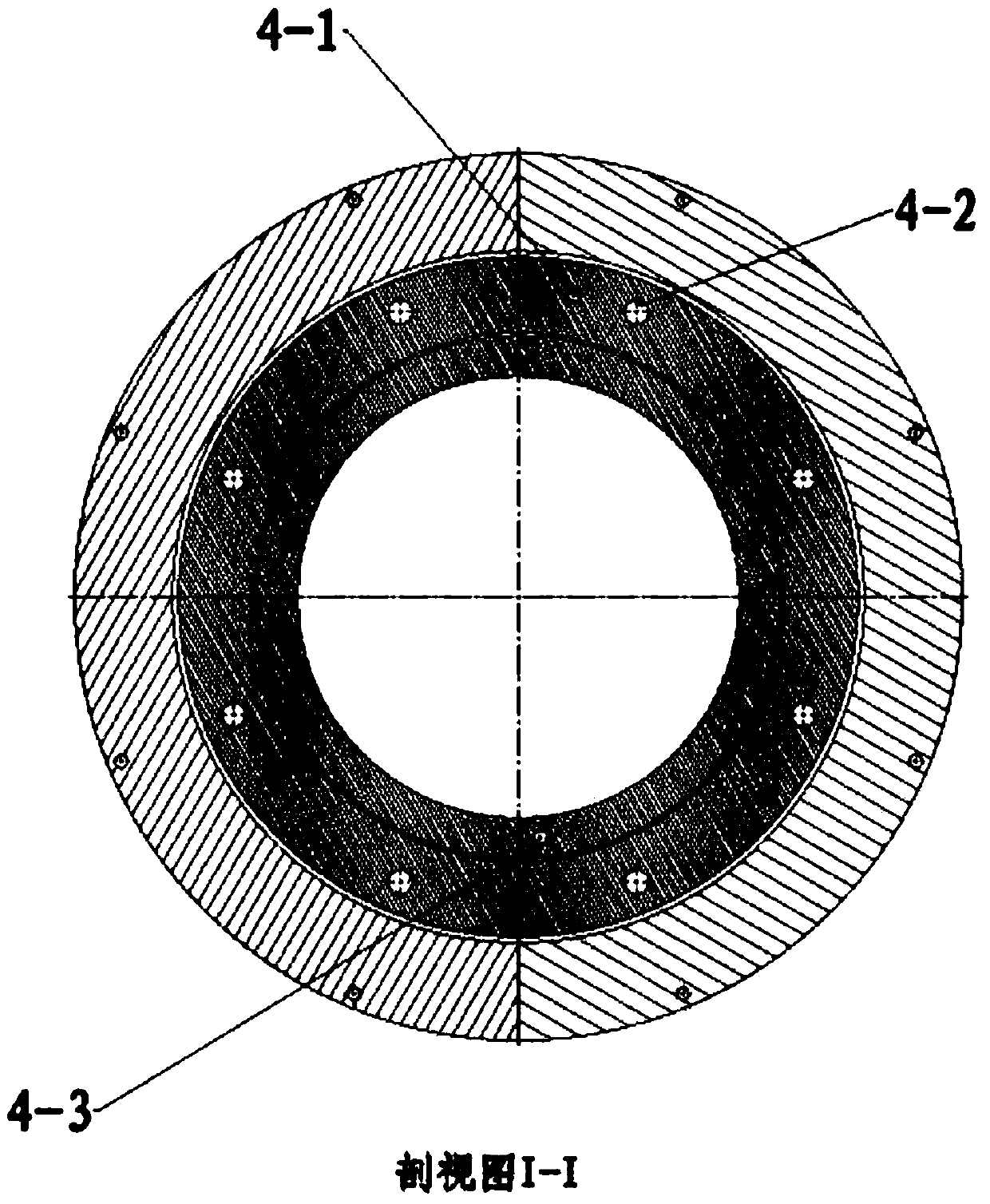

[0027] The structure of the test box is made of 304 stainless steel, and the main part of the box is a cylindrical sandwich structure, which are the insulation layer 3-1, the temperature-carrying layer 3-3, and the inner cavity 3-4.

[0028] Insulation layer 3-1 is a thin cavity formed by two cylindrical surfaces, and the interior is filled with insulation materials. Only one insulation layer is listed in the figure, because the two insulation layers are almost completely symmetrical, but they are a little different from each other because of space issues. The bottoms of the two insulation layers are all fixed to the centrifuge rotating arm 6-2 by the mounting holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com