Method for testing textile material shielding effectiveness based on live room condition

A technology of shielding effectiveness and fabric materials, which is applied in the detection field of shielding effectiveness, can solve problems such as the inability to eliminate the influence of test window results, and achieve good electromagnetic shielding ability, accurate test results, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

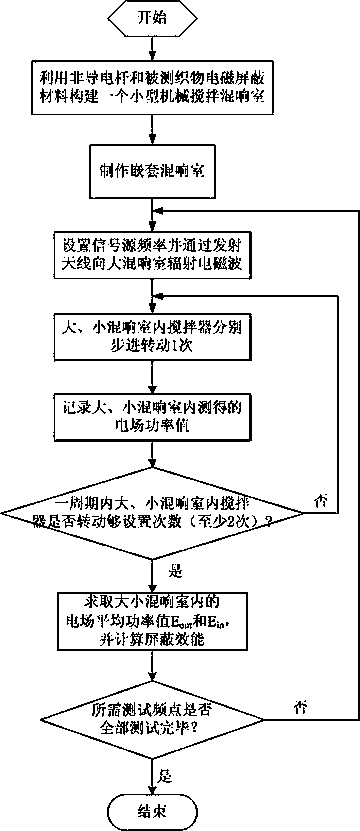

[0024] The steps of embodiment 1 are as follows, as attached figure 1 shown:

[0025] Step 1: Construct a small mechanically stirred reverberation chamber using the fabric electromagnetic shielding material to be tested:

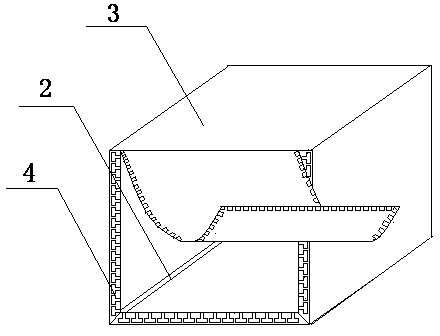

[0026] as attached figure 2 As shown, the electromagnetic shielding material 3 of the tested fabric is sewn into a rectangular cavity, one of which is provided with a zipper 4, the zipper 4 is opened, and a rectangular frame made of a non-conductive rod 2 is used to support it, and inside it Place a small agitator, and then close the zipper 4 to form a small mechanical stirring reverberation chamber 1; the small agitator is composed of a first stepping motor 6 and a first fan blade 7, and the output of the first stepping motor 6 drives the first A fan blade 7 rotates.

[0027] Step 2: Build a test platform:

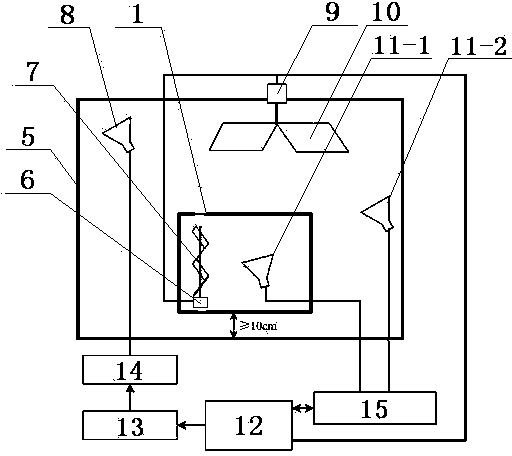

[0028] Place the small mechanically stirred reverberation chamber 1 in the test area of the large reverberation chamber 5 to form a nested rever...

Embodiment 2

[0035] The steps of embodiment 2 are as follows:

[0036] Step 1: Construct a small mechanically stirred reverberation chamber using the fabric electromagnetic shielding material to be tested:

[0037] Sew the fabric electromagnetic shielding material 3 to be tested into a conical cavity with a zipper 4 on its side, open the zipper 4, prop it up with a conical frame made of non-conductor rods 2, and place a small agitator, and then close the zipper 4 to form a small-scale mechanical stirring reverberation chamber 1; Leaf 7 rotates.

[0038] Step 2: Build a test platform:

[0039] Place the small mechanically stirred reverberation chamber 1 in the test area of the large reverberation chamber 5 to form a nested reverberation chamber;

[0040] Step 3: Follow the attached image 3 The structure and principle block diagram of the test system shown in the test system is set up, the frequency of the signal source 13 is set and electromagnetic waves are radiated to the large rev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com