Power pipeline optical cable laying auxiliary device and fabrication and construction method thereof

An auxiliary device and optical cable laying technology, which is applied in the direction of optical fiber/cable installation, etc., can solve the problems of time-consuming and labor-intensive laying of optical cables, easy access to dead ends when passing through poles, and inability to communicate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

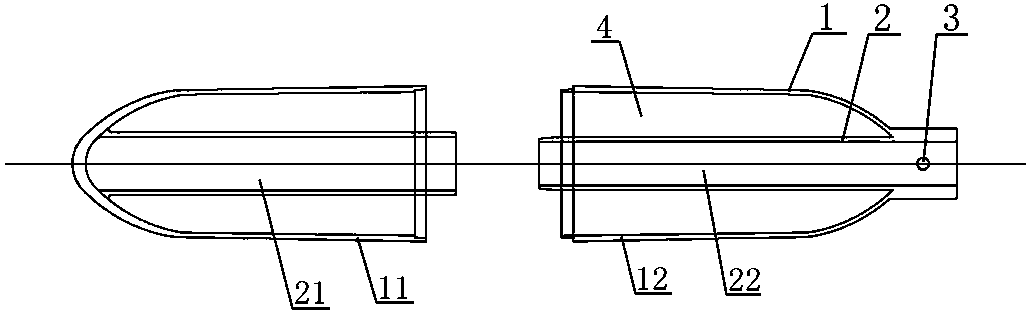

[0020] The invention will be described in detail below in conjunction with the drawings: figure 1 As shown, the optical cable laying auxiliary device of the power pipeline of the present invention includes a cylinder 1 with a cylindrical middle and two ends with circular arc tip heads. A Intermediate tube 2, one end of the intermediate tube 2 is connected to the inner wall of the arc-tip head at one end of the cylinder 1, and the other end is fixed on the arc-tip head at the other end of the cylinder and protrudes out. An optical cable connection hole 3 is horizontally opened on the end.

[0021] The cylinder body 1 of the present invention is composed of two halves that are connected to a section A cylinder body 11 and a section B cylinder body 12, and the intermediate tube 2 is also composed of two halves, a section a middle tube 21 and a section b middle tube. 22 connected composition, one end of the intermediate tube 21 of section a is fixed on the inner wall surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com