Method for using sealing strips for conducting sealing in box-type substation of wind power plant

A box-type substation and sealing strip technology, applied in the field of substations, can solve problems such as loose wire closure, electrical short circuit, and loose sealing strip doors, so as to improve safety and stability, ensure sealing performance, extend The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

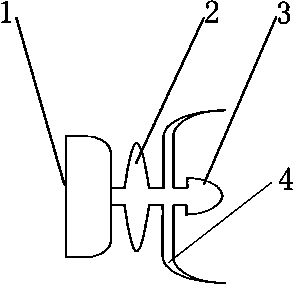

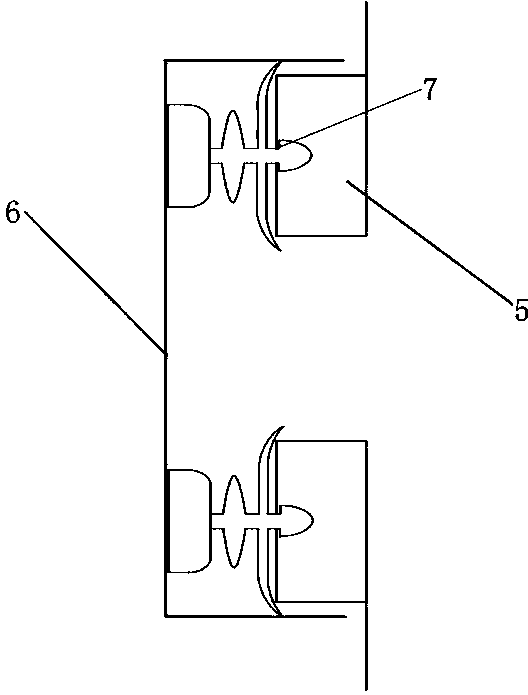

[0011] The method for sealing with a magnetic sealing strip in a box-type substation of a wind farm includes the following process steps: ① Fold the door frame steel plate of the outer door of the box-type substation into a door frame 5 with a rectangular cross section, and a A gap 7, the axis of the gap coincides with the axes of the four sides of the door frame; ② Prepare the magnetic sealing strip, the cross section of the magnetic sealing strip is composed of an integrated magnetic surface 1, elastic rubber ring 2, sealing body 4 and fixed end 3 , the plane of the magnetic surface faces outward, and an elastic rubber ring is provided between the other surface and the sealing body, and a fixed end is provided outside the sealing body, the sealing body is bent toward the fixed end, and the section of the fixed end is a mushroom head structure; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com