Inhaler component

A technology of inhalers and components, which is applied in the direction of inhalers, respirators, and medical devices, and can solve the problems of large and limited inhaler components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

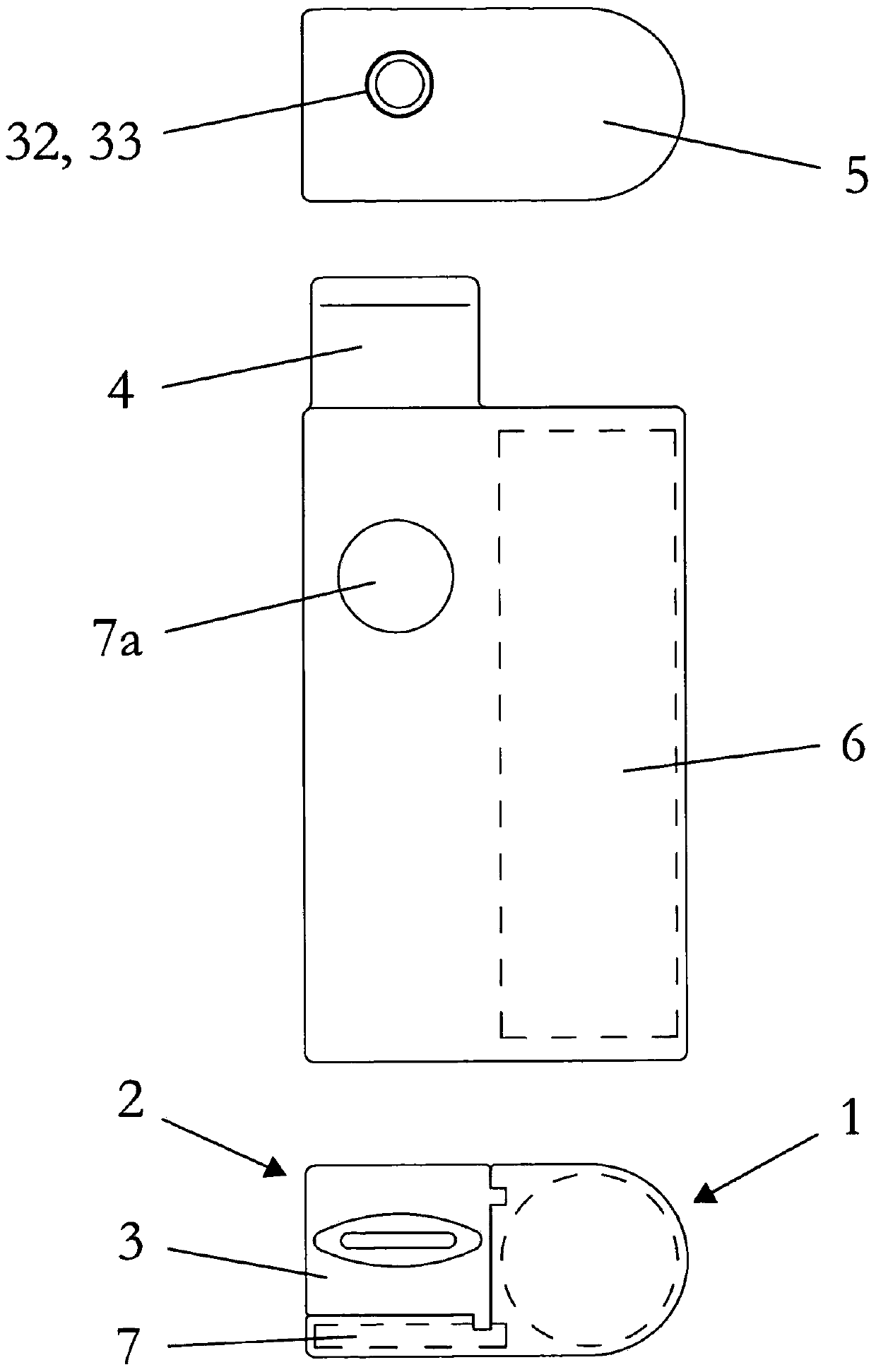

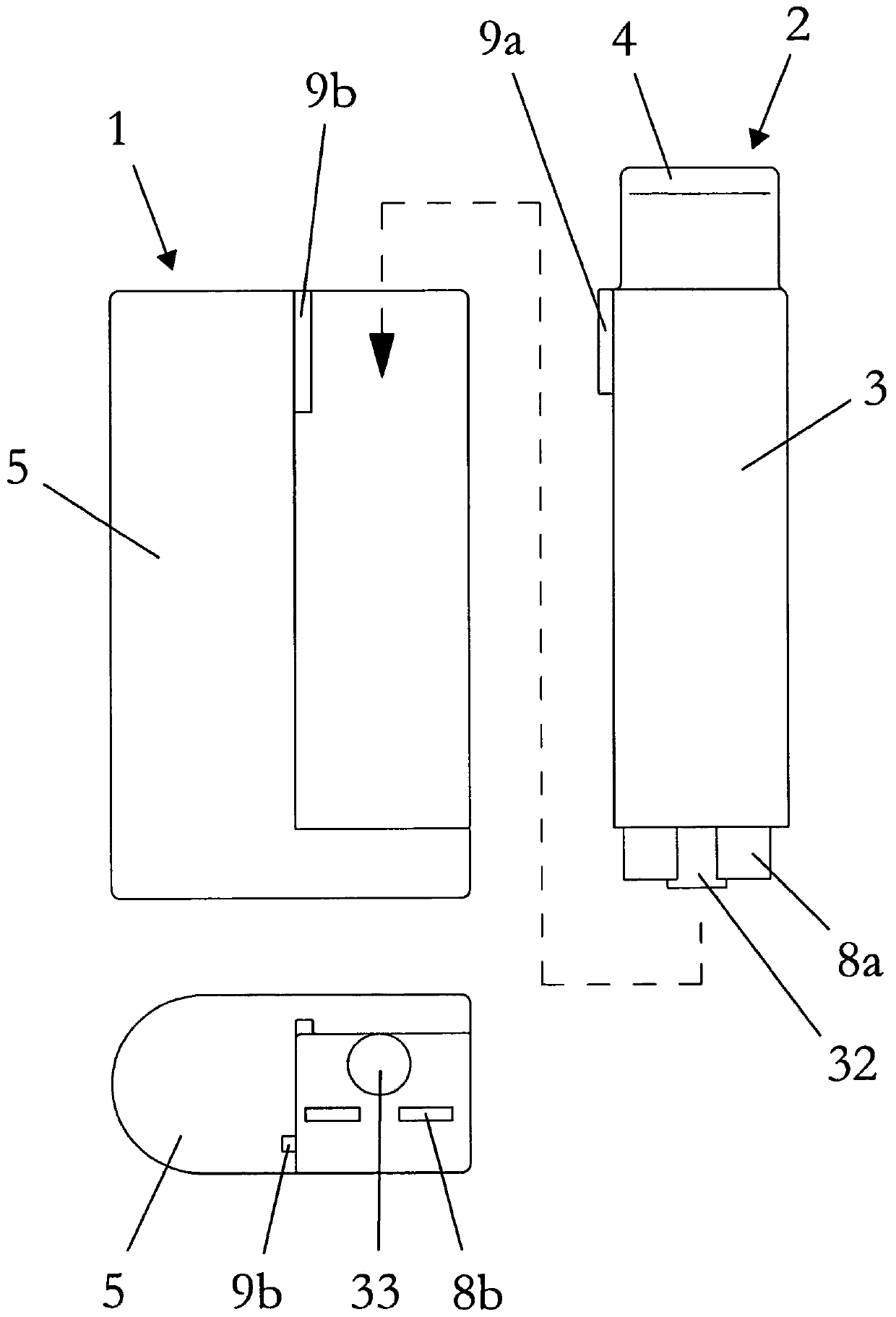

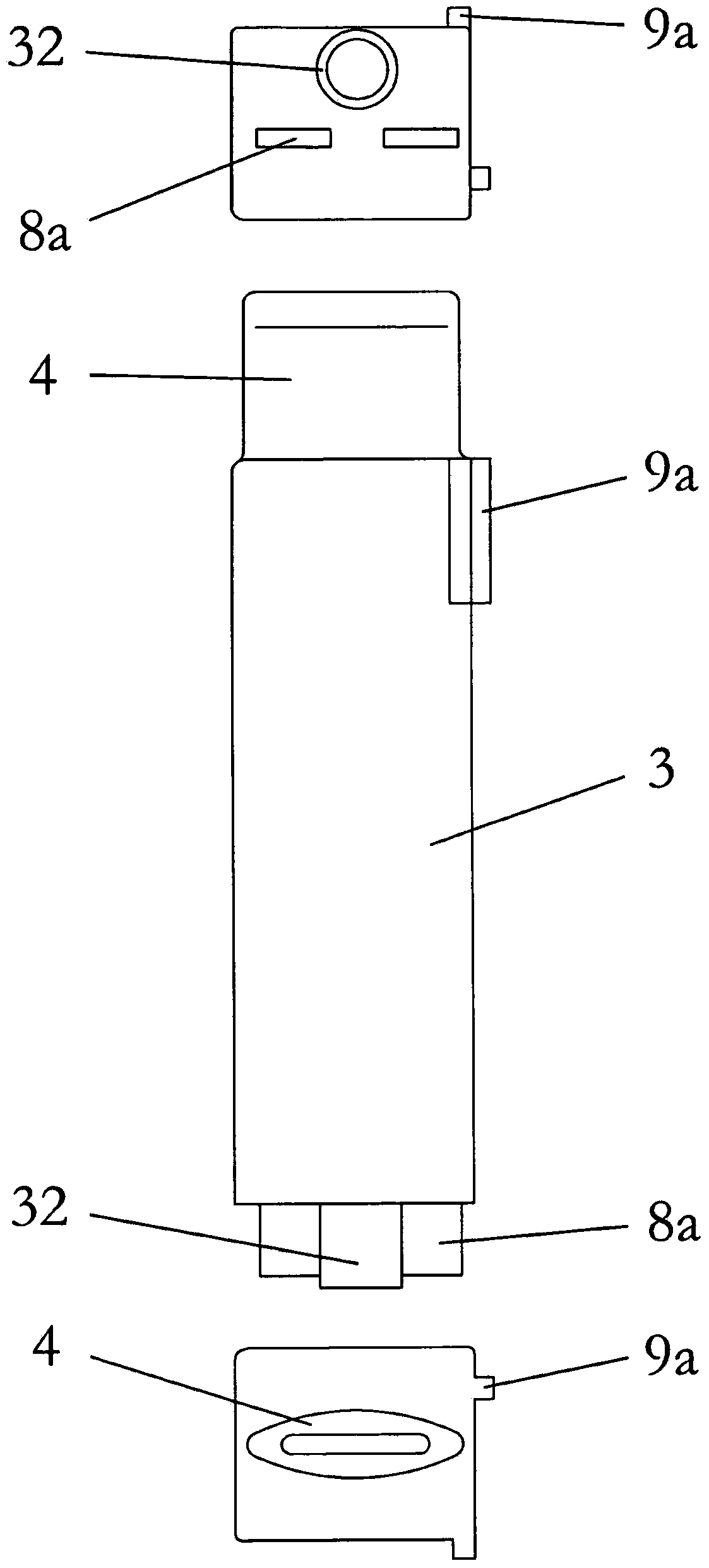

[0029] figure 1 An inhaler according to the invention is shown which is shaped and dimensioned such that the inhaler can be handled easily and comfortably by the user. The inhaler is only roughly half the size of a cigarette pack in terms of volume. In principle, the inhaler shown as an example consists of two parts, namely the inhaler part 1 and the inhaler assembly 2 .

[0030] The inhaler assembly 2 is formed by a housing 3 , which forms a pipe-shaped mouthpiece 4 on the end side. Housing 3 is preferably made of plastic. The inhaler assembly 2 contains liquid material that is electrovaporized within the housing 3 and converted into an inhalable vapor-air mixture and / or condensed aerosol. The resulting vapor-air mixture and / or condensed aerosol is supplied to the user via the mouthpiece 4 . In principle, all substances and preparations which evaporate under atmospheric conditions with as little residue as possible can be considered as liquid materials. This condition i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com