Soil box soil deep vibration compactor

A technology of shaking and soiling, which is used in devices for loosening soil, agricultural machinery and implements, suppressors, etc. It can solve the problems of not adapting to the requirements of soil deep loosening experiments, high work intensity, and low firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

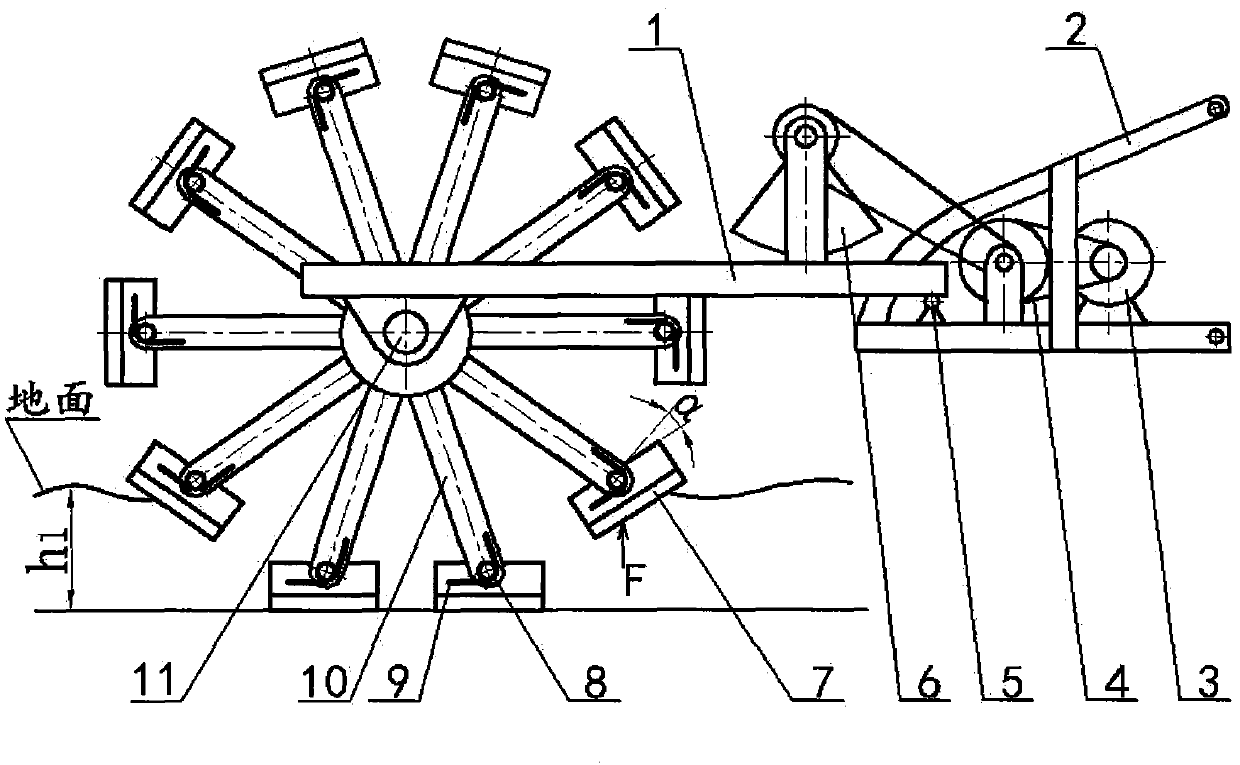

[0014] Embodiment 1: A compacting machine in which several tamping wheels work separately

[0015] Such as figure 1 and figure 2 Shown, the surface area of each tamping hammer tup of a single tamping wheel is relatively small, and the pressure on the soil is relatively large, so it can go deep into the soil and compact the soil.

Embodiment 2

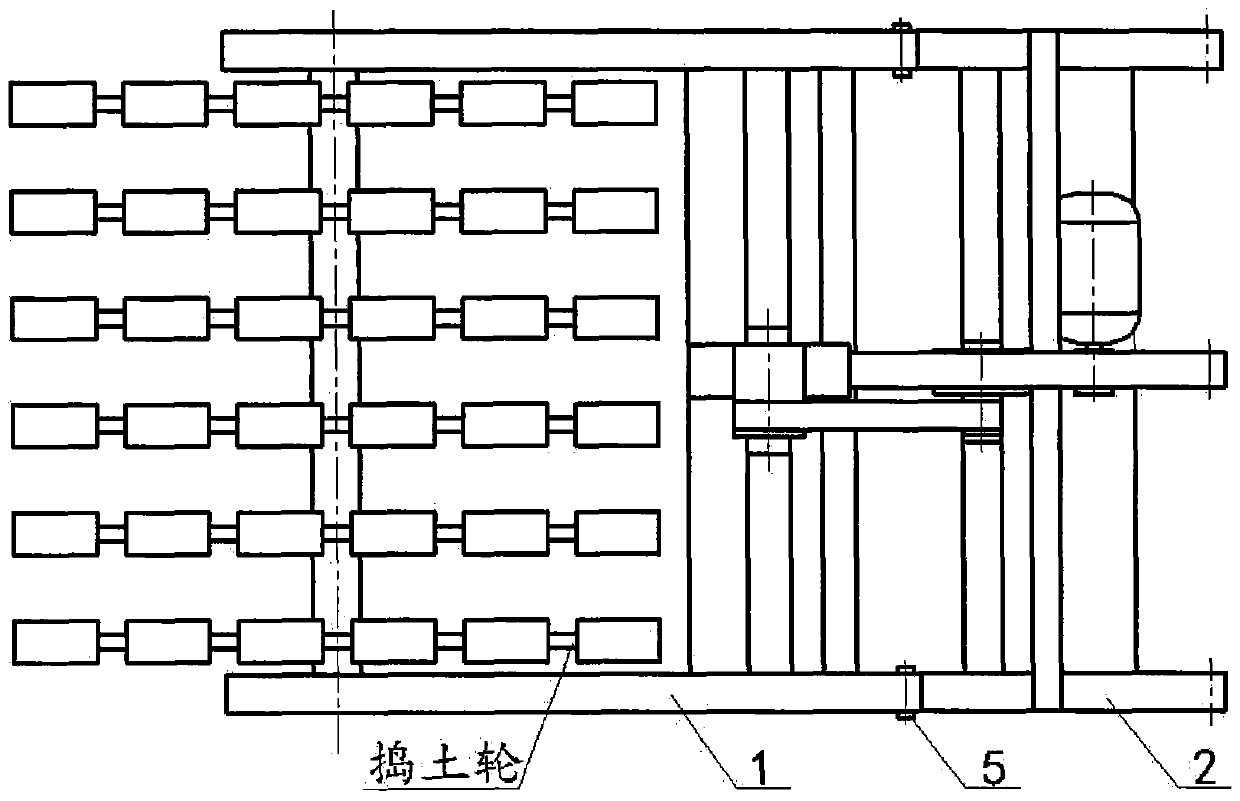

[0016] Embodiment 2: A compacting machine in which a plurality of tamping wheels are combined to work

[0017] Such as image 3 As shown, multiple ramming wheels ( image 3 Shown as two) combined together, can increase the surface area of the tamping hammer tup, the pressure of the soil on the tup reduces, and the tup can only go deep into the shallower part of the soil for compaction.

Embodiment 3

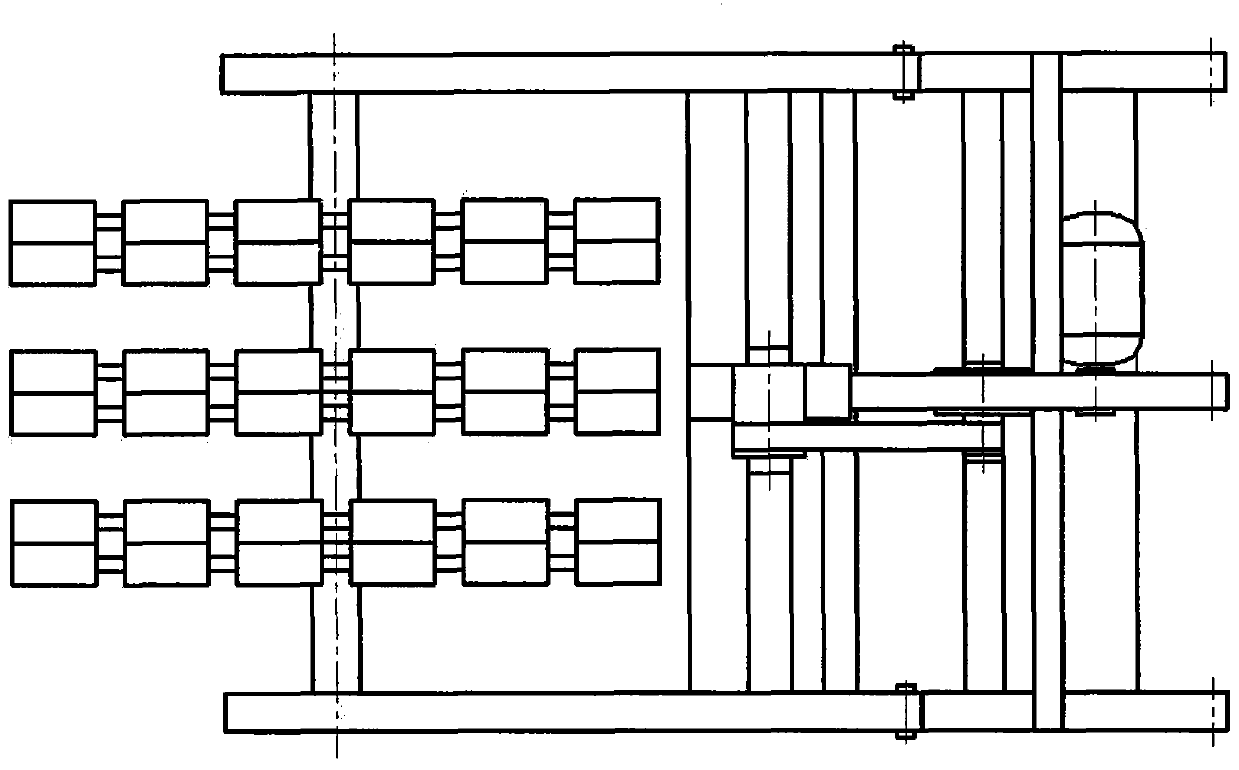

[0018] Embodiment 3: A vibrating machine with different diameter tamping wheels working in combination

[0019] Such as Figure 4 As shown, the tamping wheel in this embodiment three includes a large-diameter tamping wheel and a small-diameter tamping wheel, which can realize the simultaneous vibration of the upper and lower layers of soil with different depths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com