Production technology for soft particle baits and material pressing device for storing soft particle baits

A production process and soft particle technology, applied in fishing accessories, fishing, applications, etc., can solve the problems of adding accessories, limiting fishing varieties, and slow emission of bait flavor pheromones.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take crucian carp fishing as an example

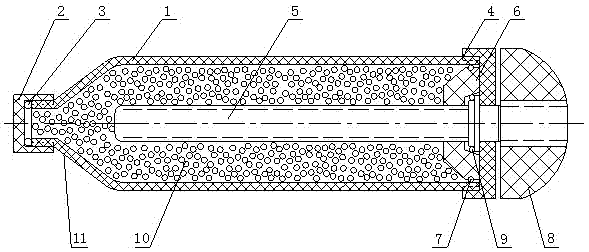

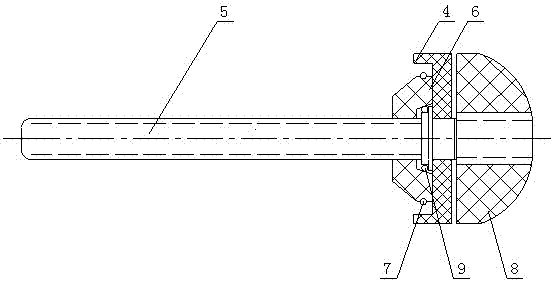

[0034] Such as figure 1 and 2 As shown, the soft particle bait production process of the present invention comprises the following steps:

[0035] (1) Mix crushed grains, crushed herbs, amino acids and fish attractants as raw materials and mix evenly. The mass ratio of grains, herbs, amino acids and fish attractants is 93:1:0.2:0.5, then add water and medicinal wine, The mass ratio of raw materials, water and medicinal wine is 100:100:2, stir evenly to form viscous bait;

[0036] (2) Put the above-mentioned viscous bait into the equipment that is constantly rotating and stirring for high-temperature sterilization treatment. The temperature during the high-temperature sterilization treatment is 125°C and the time is 8s, and it flows into the next process while being sterilized;

[0037] (3) Enter the flowing water of the above-mentioned high-temperature sterilized bait into the molding equipment, extrude it into a cylindrical ...

Embodiment 2

[0042] Take grass carp fishing as an example

[0043] Such as figure 1 and 2 As shown, the soft particle bait production process of the present invention comprises the following steps:

[0044] (1) Mix crushed grains, crushed herbs, amino acids and fish attractants as raw materials and mix evenly. The mass ratio of grains, herbs, amino acids and fish attractants is 96:2:0.5:1.5, then add water and medicinal wine, The mass ratio of raw materials, water and medicinal wine is 105:100:3, stir evenly to form viscous bait;

[0045] (2) Put the above-mentioned viscous bait into the equipment that is constantly rotating and stirring for high-temperature sterilization treatment. The temperature during the high-temperature sterilization treatment is 125°C and the time is 8s, and it flows into the next process while being sterilized;

[0046] (3) Enter the flowing water of the above-mentioned high-temperature sterilized bait into the molding equipment, extrude it into a cylindrical sh...

Embodiment 3

[0051] Take carp fishing as an example

[0052] Such as figure 1 and 2 As shown, the soft particle bait production process of the present invention comprises the following steps:

[0053] (1) Mix crushed grains, crushed herbs, amino acids and fish attractants as raw materials and mix evenly. The mass ratio of grains, herbs, amino acids and fish attractants is 98:3:1:3, then add water and medicinal wine, The mass ratio of raw materials, water and medicinal wine is 100:100:5, stir evenly to form viscous bait;

[0054] (2) Put the above-mentioned viscous bait into the equipment that is constantly rotating and stirring for high-temperature sterilization treatment. The temperature during the high-temperature sterilization treatment is 125°C and the time is 8s, and it flows into the next process while being sterilized;

[0055] (3) Enter the flowing water of the above-mentioned high-temperature sterilized bait into the molding equipment, extrude it into a cylindrical shape and in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com