Novel star-like rotation platform

A rotating platform and a new type of star technology, applied in the field of a new type of star-shaped rotating platform, can solve the problems of increasing labor capital, low production efficiency, procrastination and cumbersome processes, etc., to reduce the number of clamping and unloading, reduce costs, and reduce production the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

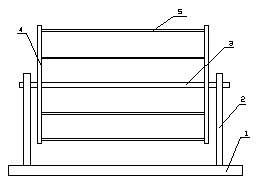

[0008] The new star-shaped rotating platform includes a bottom plate 1, a supporting plate 2, a star-shaped rotating platform 4, a rotating main shaft 3, and a rotating secondary shaft 5. The rotating main shaft 3 crosses the center of the star-shaped rotating platform 4 and is set on the support On the plate 2, the supporting plate 2 is connected with the bottom plate 1, and eight rotating secondary shafts 5 are arranged in parallel on the star-shaped rotating platform 4, and the rotating secondary shafts 5 are arranged equally with the rotating main shaft 3 as the center.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com