Expandable underactuated cable-rod truss type mechanical claw

A robotic gripper and truss-type technology, which is applied in the field of modular robotic grippers, can solve the problems of poor shape adaptability of target objects, difficult expansion of SARAH grippers, and heavy weight of SARAH grippers, and achieve strong target adaptability and mature processing technology , the effect of rich material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

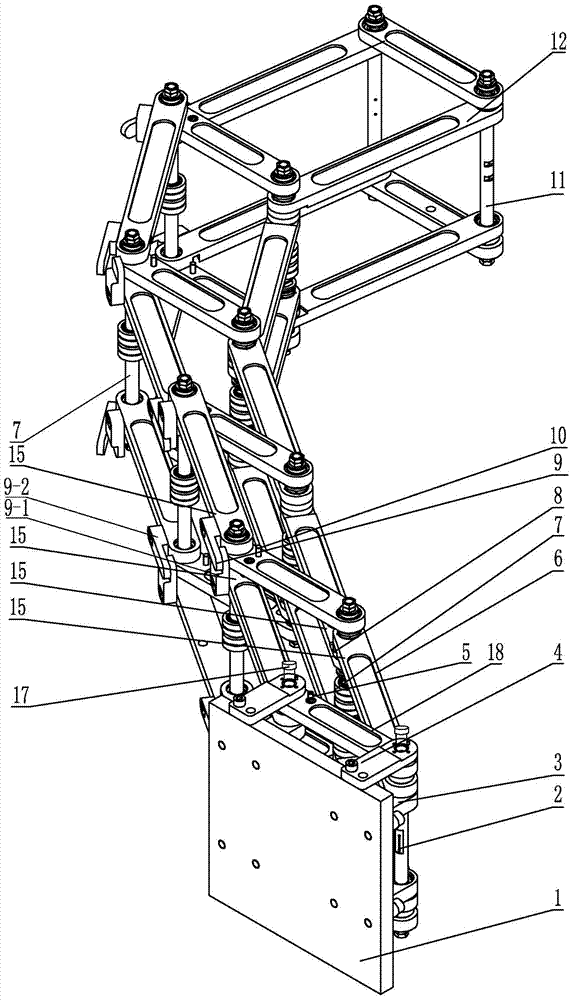

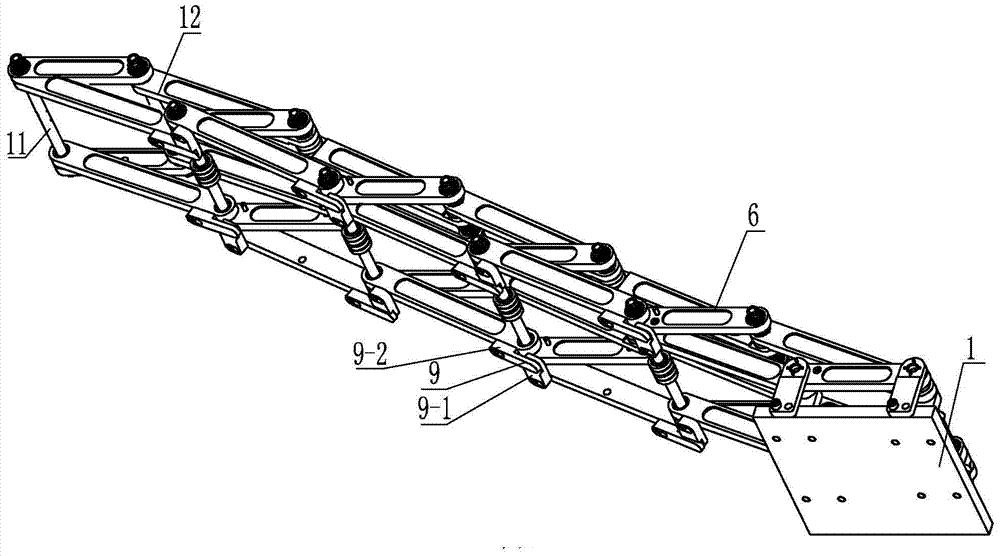

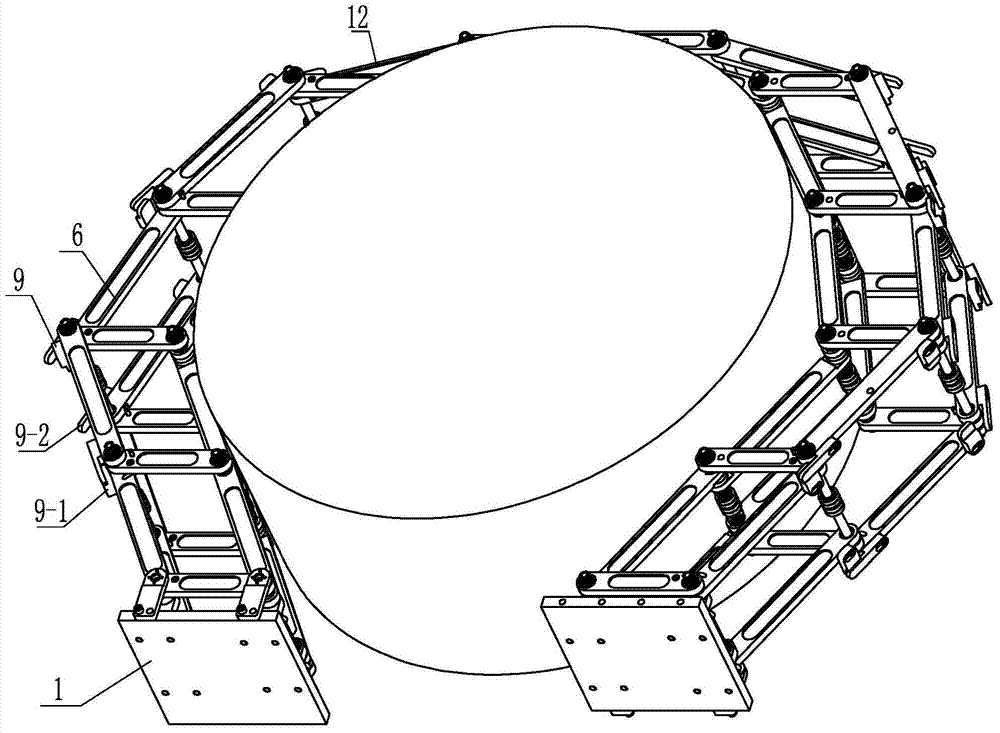

[0019] Specific implementation mode one: combine Figure 1-Figure 4 Explain that an expandable underactuated cable-bar truss-type robotic gripper in this embodiment includes a front-end connection device, an inter-bar rotation angle limiting mechanism 9, an end cable-bar truss 12, ropes, multiple positioning columns 10, and multiple expandable modules. Cable-strut truss 6;

[0020] The front connecting device comprises a connecting plate 1, two rope shafts 2, two spacer posts 5, two mounting plates 4, two transition plates 18 and four supporting plates 3, and one end surface of the connecting plate 1 is equipped with four A support plate 3, four support plates 3 are arranged in a rectangular array, two support plates 3 on the same side in the vertical direction are provided with rope shafts 2, and two mounting plates 4 are installed on the upper surface of the connecting plate 1, A motor 17 is fixedly installed on each mounting plate 4, and the output shaft of the motor 17 is...

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 To illustrate, the frictional damping metal sheet 8 in this embodiment is a steel sheet. Such a setting is cheap and easy to obtain, and changing the pressure at both ends of the frictional damping can change the resistance torque between the two rods, thereby realizing the controllable design of the underactuated mechanism. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination figure 1 To illustrate, the frictional damping metal sheet 8 in this embodiment is an aluminum sheet. Such a setting is cheap and easy to obtain, and changing the pressure at both ends of the frictional damping can change the resistance torque between the two rods, thereby realizing the controllable design of the underactuated mechanism. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com