Antifreezing suction coarse water filter

A water filter and filter disc technology, which is applied in fresh water production equipment, ship parts, ships, etc., can solve the problems of difficult thawing and achieve good thawing effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

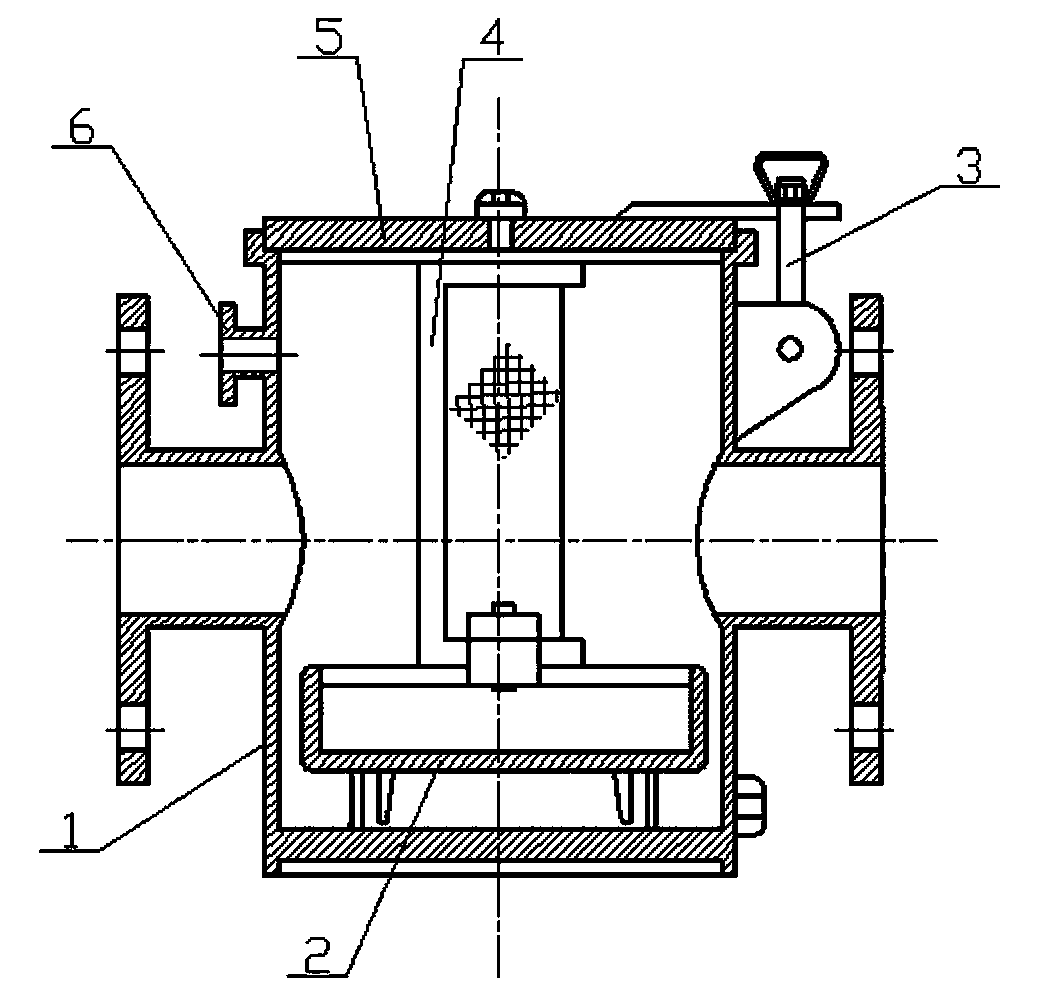

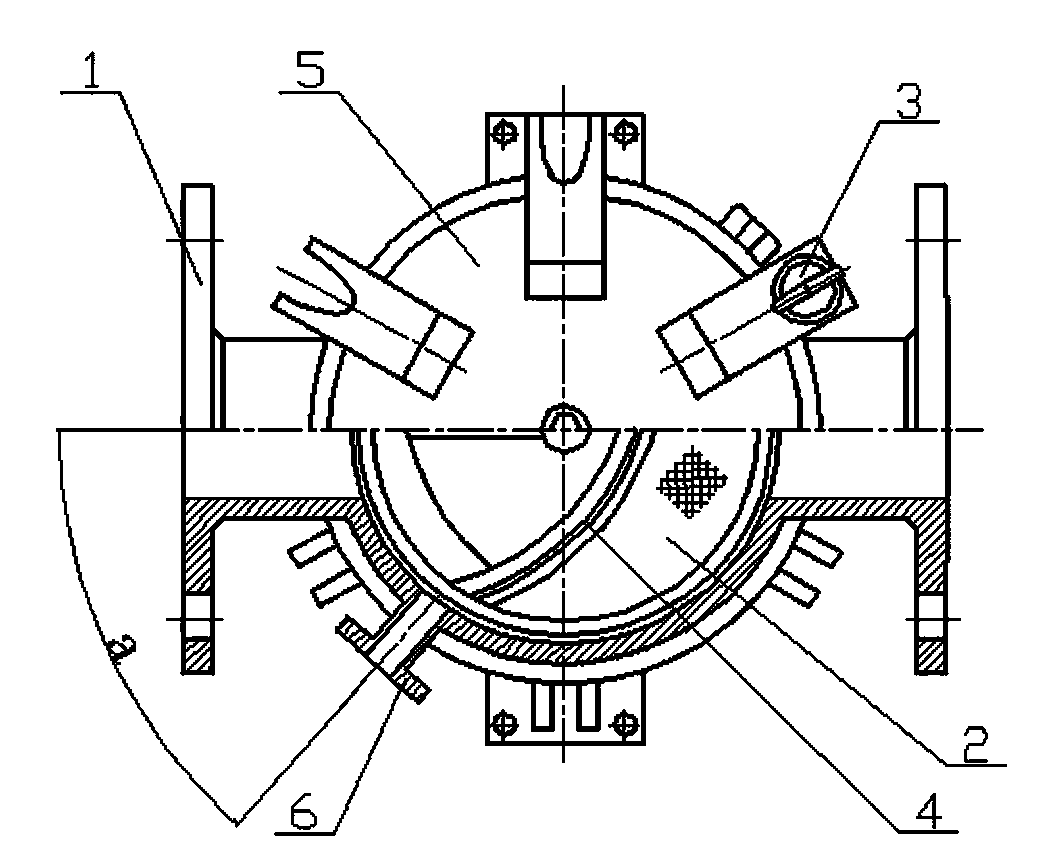

[0013] figure 1 The shown antifreeze suction coarse water filter includes a housing 1, a filter disc 2, a locking buckle 3, a filter element 4, an upper cover 5 and a branch pipe 6. The housing 1 is a bottomed container provided with an upper cover 5, and the left and right sides of the longitudinal inner cavity are each provided with a flange to communicate with the inner cavity, the left side is the inlet, and the right side is the outlet. The filter disc 2 is a disc-shaped sieve. The filter disc 2 is placed flat on the bottom of the inner cavity of the housing 1. The arc-shaped filter element 4 stands on the filter disc 2 and is connected by the upper cover 5 and the locking buckle 3. , forming a filtering structure bounded by the filter core 4. The flange connecting pipes located on both sides of the filter element 4 respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com