Ceiling type reciprocating short yarn dropping device

A ceiling-mounted, doffing technology, applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, can solve the problems of large load, consumption of renewable electric energy, and large energy consumption, and achieve reasonable structure, reduce load, The effect of simplifying the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

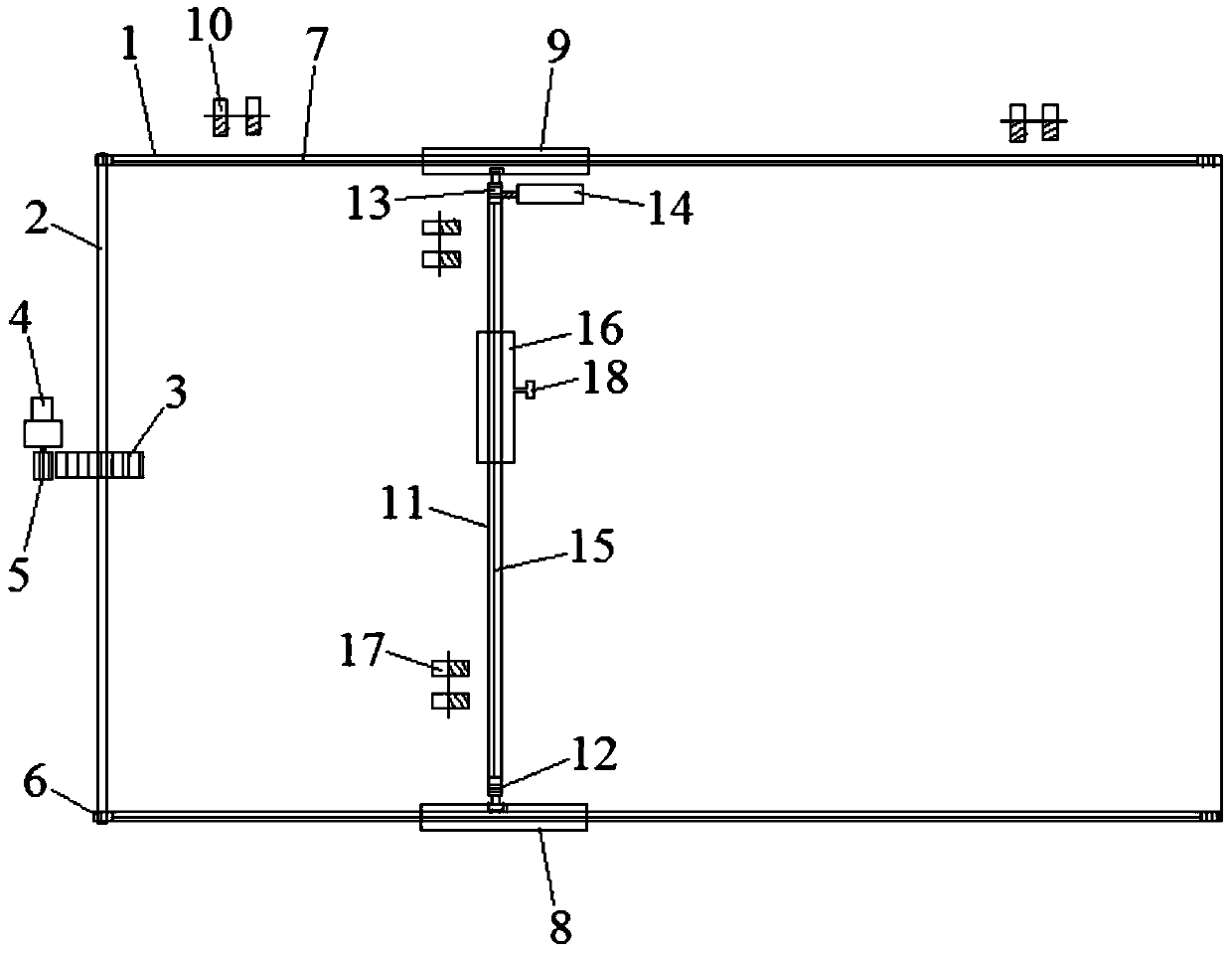

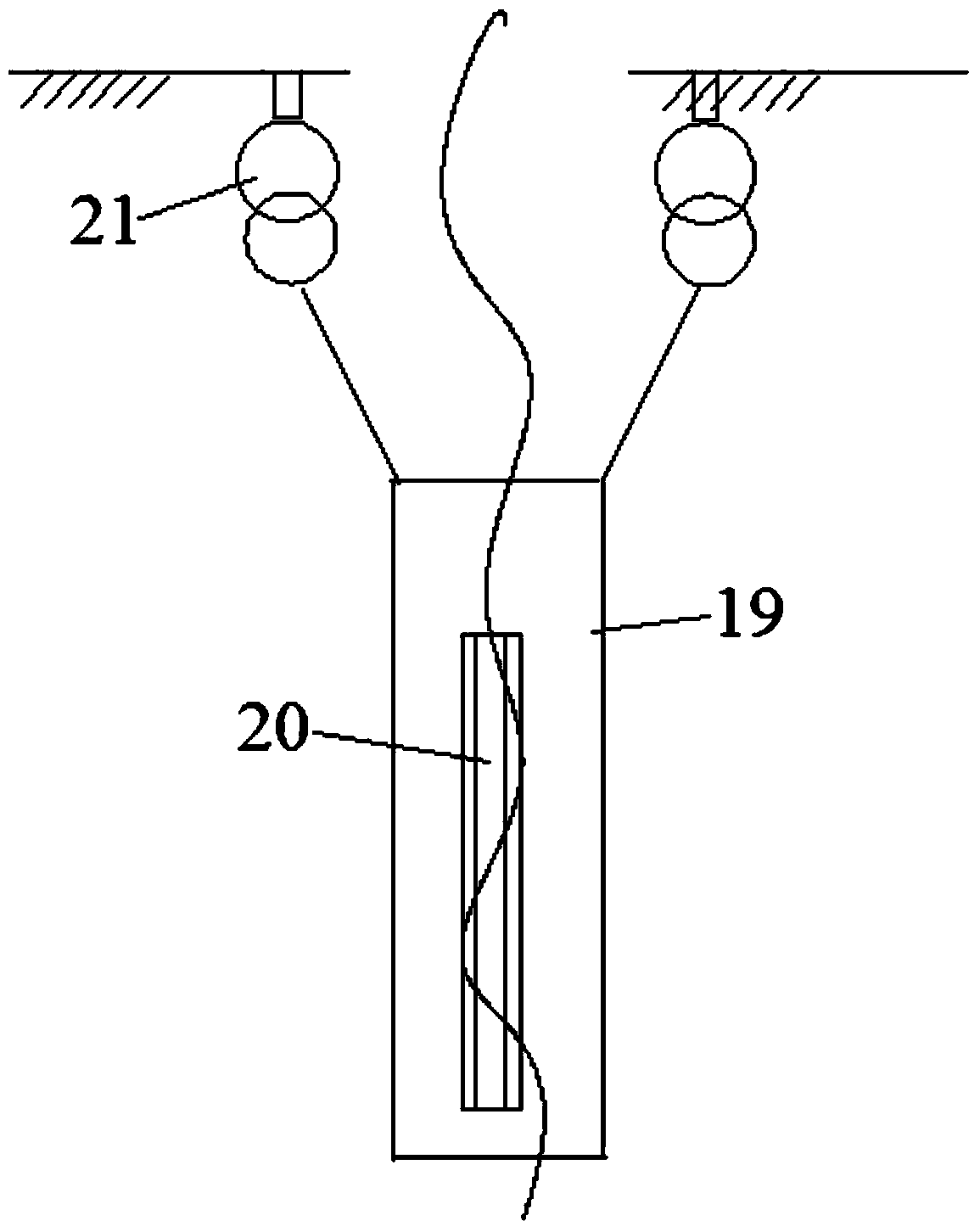

[0017] see figure 1 , 2 , a short-suspended ceiling-type reciprocating doffing device, including a frame 1 hoisted above the silk barrel, the left end of the frame 1 is rotated and installed with a first longitudinal shaft 2, and a first driven gear is installed on the first longitudinal shaft 2 3. A first motor 4 is provided on one side of the first longitudinal shaft 2. The end of the output shaft of the first motor 4 is equipped with a first driving gear 5 meshing with the first driven gear 3. The first longitudinal shaft 2 Both ends are equipped with front and rear gears 6 respectively, and front and rear transverse chains 7 connected with the front and rear gears 6 are respectively installed on the two ends of the first longitudinal shaft 2 on the frame 1, and the bottoms of the front and rear transverse chains 7 The front and rear transverse sliding barrels 8 and 9 are respectively fixedly installed, and the outer side of the frame 1 is respectively provided with transv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com