Weathering crust deposit type rare earth ore compound leaching agent

A weathering crust leaching type, rare earth ore technology, applied in the direction of improving process efficiency, can solve the problems of reducing clay ore, hindering the leaching process of rare earth, changing the hydrophilicity of clay minerals, etc., to achieve improved leaching, good anti-swelling Effect, effect of strong hydration swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

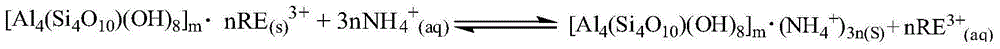

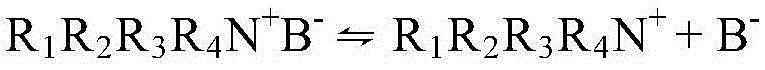

Method used

Image

Examples

Embodiment 1

[0028] Weigh 250.0g of the dried weathering crust elution-type rare earth ore and put it into a glass column, and prepare a composite leaching agent (mass concentration) according to the following components: di-n-propylamine hydrochloride 4g / L, ammonium chloride 6g / L , and use 2.0mol / L hydrochloric acid to adjust the pH of the solution to 4.5, and use this composite leaching agent to add to the column at a solid-to-liquid ratio of 1:2 (g:mL), and adjust the flow rate to 0.52mL / min. Column leaching was carried out for the accumulated rare earth ore, and the rare earth content in the leachate was detected with xylenol orange as an indicator under the condition of pH=5.5, and detected by EDTA volumetric method, and the calculated rare earth leaching rate was 93.66%;

[0029] Determination of clay mineral linear expansion rate:

[0030] Weigh 2.0g of the weathered crust elution-type rare earth ore after vacuum drying, keep the pressure at 8.0MPa, press the tablet on the tablet ma...

Embodiment 2

[0039] The implementation method is the same as in Example 1, and the composite leaching agent is prepared according to the following components: 1g / L di-n-propylamine hydrochloride, 5g / L ammonium chloride, and hydrochloric acid to adjust the pH of the solution to 4.0, and use this composite leaching solution to treat weathering shells. The column leaching of the leaching type rare earth ore was carried out, and the rare earth content of the leachate was detected. The rare earth leaching rate was 68.76%, and the expansion rate was 1.879%.

[0040] Di-n-propylamine hydrochloride is added as an anti-swelling agent, which has a synergistic effect with the leaching agent, and has good leaching effect and anti-swelling effect.

Embodiment 3

[0042] The implementation method is the same as in Example 1, and the composite leaching agent is prepared according to the following components: 15g / L di-n-propylamine hydrochloride, 30g / L ammonium chloride, hydrochloric acid to adjust the pH of the solution to 6.0, and use this composite leaching solution to treat weathering shells. The column leaching of the leaching type rare earth ore was carried out, and the rare earth content of the leachate was detected. The rare earth leaching rate was 95.41%, and the expansion rate was 2.010%.

[0043] Di-n-propylamine hydrochloride is added as an anti-swelling agent, which has a synergistic effect with the leaching agent, and has good leaching effect and anti-swelling effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com