Face pipe assembly for guard bar

A surface tube and component technology, applied in the direction of fences, bridge parts, stepped structures, etc., can solve the problems of shortened service life of guardrails and guard windows, no adjustable space, affecting installation efficiency, etc., and achieves simple structure and beautiful appearance. , the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

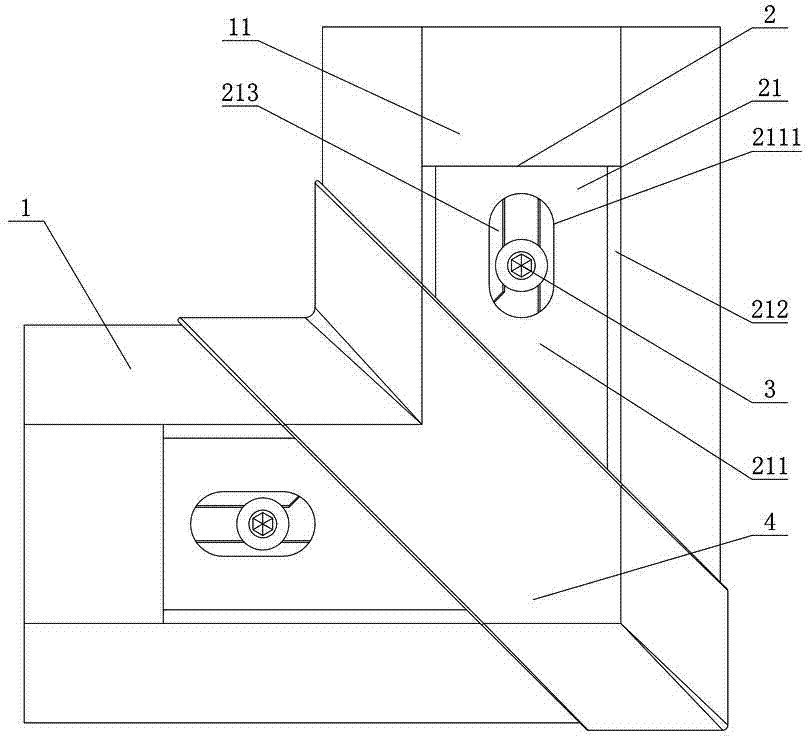

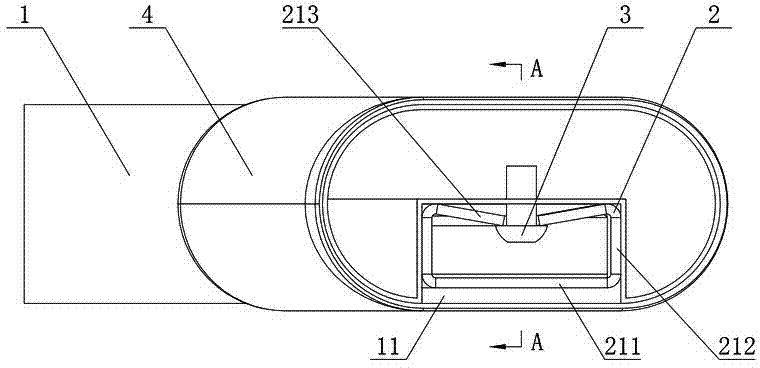

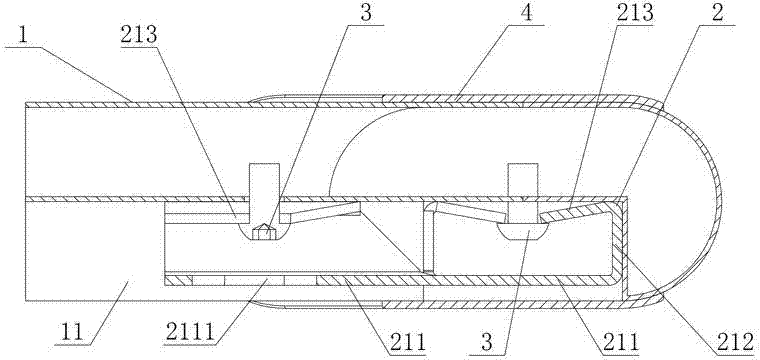

[0035] Figure 1 to Figure 6 It shows the first embodiment of the surface tube assembly used for guardrails in the present invention, which includes a surface tube 1 and an expansion joint 2. The surface tube 1 is provided with a groove 11 at the bottom, and its structure is simple, easy to install, and easy to assemble. , insert the two ends of the expansion joint 2 into the grooves 11 of the two surface pipes 1 respectively, and then use the fastener 3 to connect the two ends of the expansion joint 2 to the two surface pipes 1 respectively, so as to realize The pre-installation of the expansion joint 2 and the two surface pipes 1, when the fastener 3 is further tightened, the expansion joint 2 expands and respectively expands and connects with the inner walls of the grooves 11 of the two surface pipes 1, thereby realizing installation. In terms of traditional direct screw connection, the expansion joint 2 can be adjusted by sliding in the groove 11, that is, the connection p...

Embodiment 2

[0043] Figure 7 to Figure 11 It shows the second embodiment of the surface pipe assembly used for the guardrail of the present invention. This assembly is basically the same as Embodiment 1, the only difference is that the fastener 3 is a jacking thread, and one end of the fastener 3 is screwed to the bottom plate 211 , the other end is against the two folded plates 213, and the jacking force of the fastener 3 makes the two folded plates 213 expand. The structure is simple and easy, and when the fastener 3 is tightened, the fastener 3 The end drives the folding plate 213 to expand and drives the side plate 212 to expand to both sides to expand and connect with the inner wall of the groove 11. It is effectively shared with the side plate 212 to strengthen the connection effect, and this structure does not need to open holes on the surface pipe 1 , which improves the load-bearing strength of the surface pipe 1 .

[0044] In this embodiment, the bottom plate 211 is provided wit...

Embodiment 3

[0046] Figure 12It shows the second embodiment of the surface pipe assembly used for the guardrail of the present invention. This assembly is basically the same as Embodiment 1, the only difference is that the two sockets of the decorative shell 4 are perpendicular to each other, so that the two The plug-in end of the surface pipe 1 can always be covered by the decorative shell 4 without setting an inclined surface, and it can also ensure that the two surface pipes 1 are also perpendicular to each other. It is suitable for the corner of the guardrail. Its structure is simple, beautiful and durable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com