fence

A guardrail and column technology, which is applied in the connection of poles, connecting components, mechanical equipment, etc., can solve the problems of shortened service life of guardrails and guard windows, no adjustable space, affecting installation efficiency, etc., and achieves simple structure, anti-push and pull. The effect of improving capacity and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

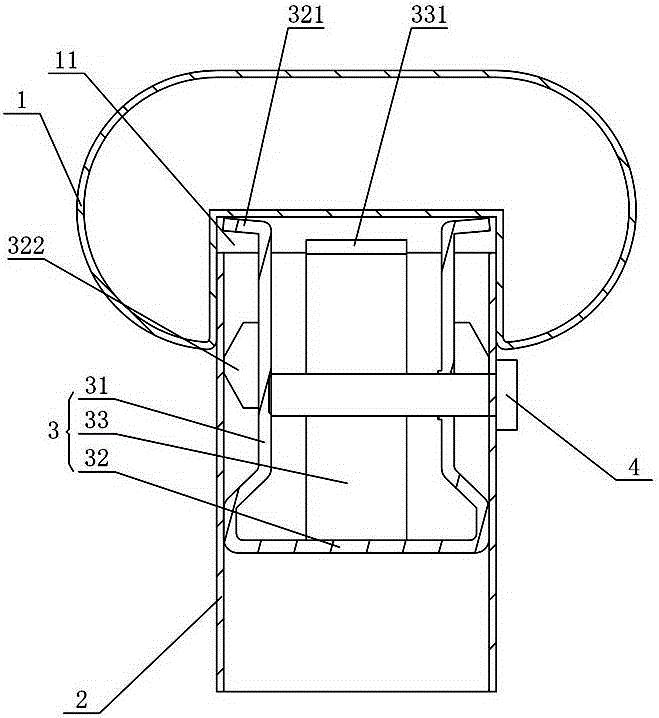

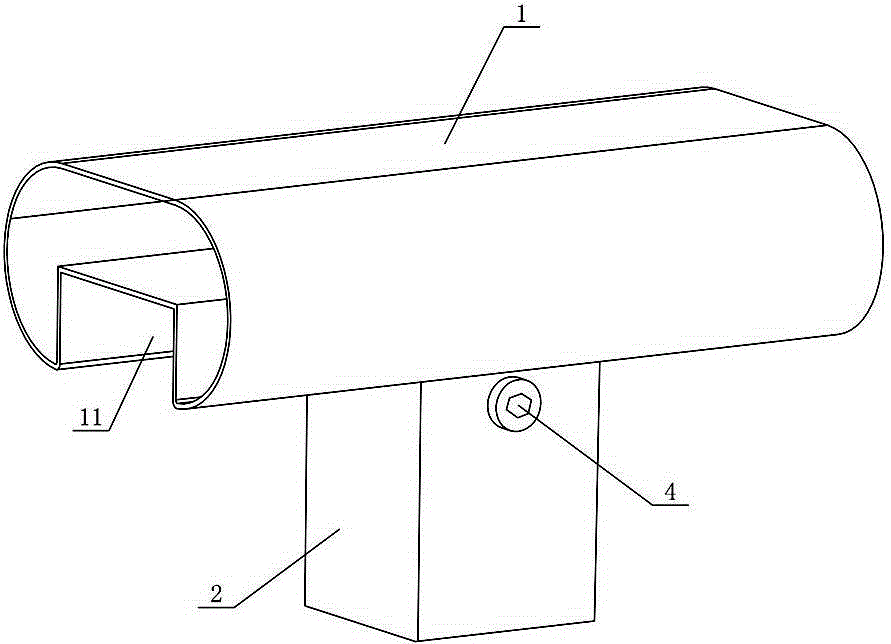

[0032] Figure 1 to Figure 4 Shown is the first embodiment of a guardrail of the present invention, the guardrail includes a surface tube 1, a column 2 and an expansion joint 3, the bottom of the surface tube 1 is provided with a groove 11, and its structure is simple and easy to install. When assembling, Insert one end of the expansion joint 3 into the column 2 first, and connect the expansion joint 3 with the column 2 with the top wire 4 to realize the pre-installation of the expansion joint 3 and the column 2, and then extend the expansion joint 3 The part to the outside of the column 2 is sleeved in the groove 11, and when the top screw 4 is further tightened, the expansion joint 3 expands and simultaneously expands and connects with the inner wall of the column 2 and the inner wall of the groove 11, thereby realizing the surface tube 1 and the column 2 Compared with the traditional direct screw connection, the guardrail is a plug-in structure, that is, the column 2 and th...

Embodiment 2

[0038] Figure 5 to Figure 7 The second embodiment of a guardrail of the present invention is shown, which is basically the same as that of Embodiment 1, the only difference being that both sides of the side plate 32 are bent inwardly with reinforcing ribs 323, and the reinforcing ribs 323 can on the one hand Supporting the inner wall of the column 2, on the other hand, can prevent the side plate 32 from bending and deforming during the jacking process, and improve the stability of the connection. One of the side plates 32 is provided with a positioning hole 324, which is passed through by a fastener The pipe wall of the column 2 is threaded with the positioning hole 324 to facilitate the pre-installation of the expansion joint 3 and the column 2. The other side plate 32 is inclined to the inside of the expansion joint 3, that is, a formation is formed between the side plate 32 and the column 2. There is room for the side plates 32 to expand and deform. When the jacking screw ...

Embodiment 3

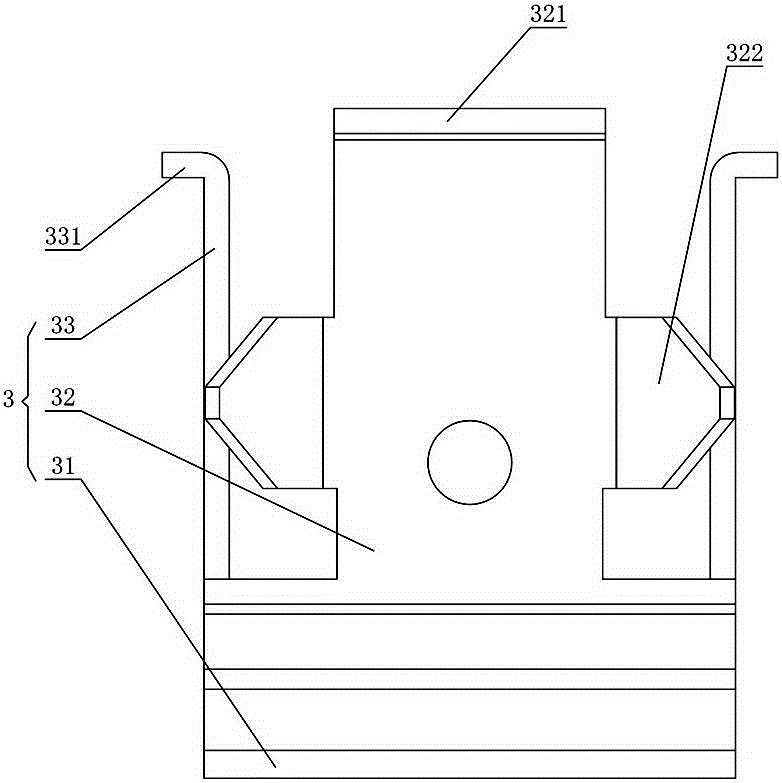

[0040] Figure 8 to Figure 11A third embodiment of a guardrail of the present invention is shown, which is basically the same as that of Embodiment 1, the only difference being that the expansion joint 3 includes a bottom plate 31, and side plates 32 are bent on both sides of the bottom plate 31, and the side plates 32 ends are bent with a first expansion plate 321 protruding to the outside of the column 2, and a third expansion plate 325 is bent inward on both sides of one of the side plates 32, and the end of the third expansion plate 325 is bent There is an inwardly inclined jacking plate 326. The jacking screw 4 is threadedly connected with the side plate 32 and passes through the jacking plate 326 to offset the other side plate 32. The structure is simple and the operation is convenient. When the jacking screw 4 is tightened, The lifting plate 326 expands to both sides and drives the two third expansion plates 325 to expand and connect with the inner wall of the column 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com