Design method of light reflection cup of large-angle LED (Light Emitting Diode) bulb lamp

A technology of LED bulb lamp and design method, applied in the direction of light source, reflector, light source fixation, etc., can solve the problems of narrow irradiation range, short life, large dark area of lamps, etc., achieve convenient assembly and production, and increase the luminous angle , the effect of increasing the light angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

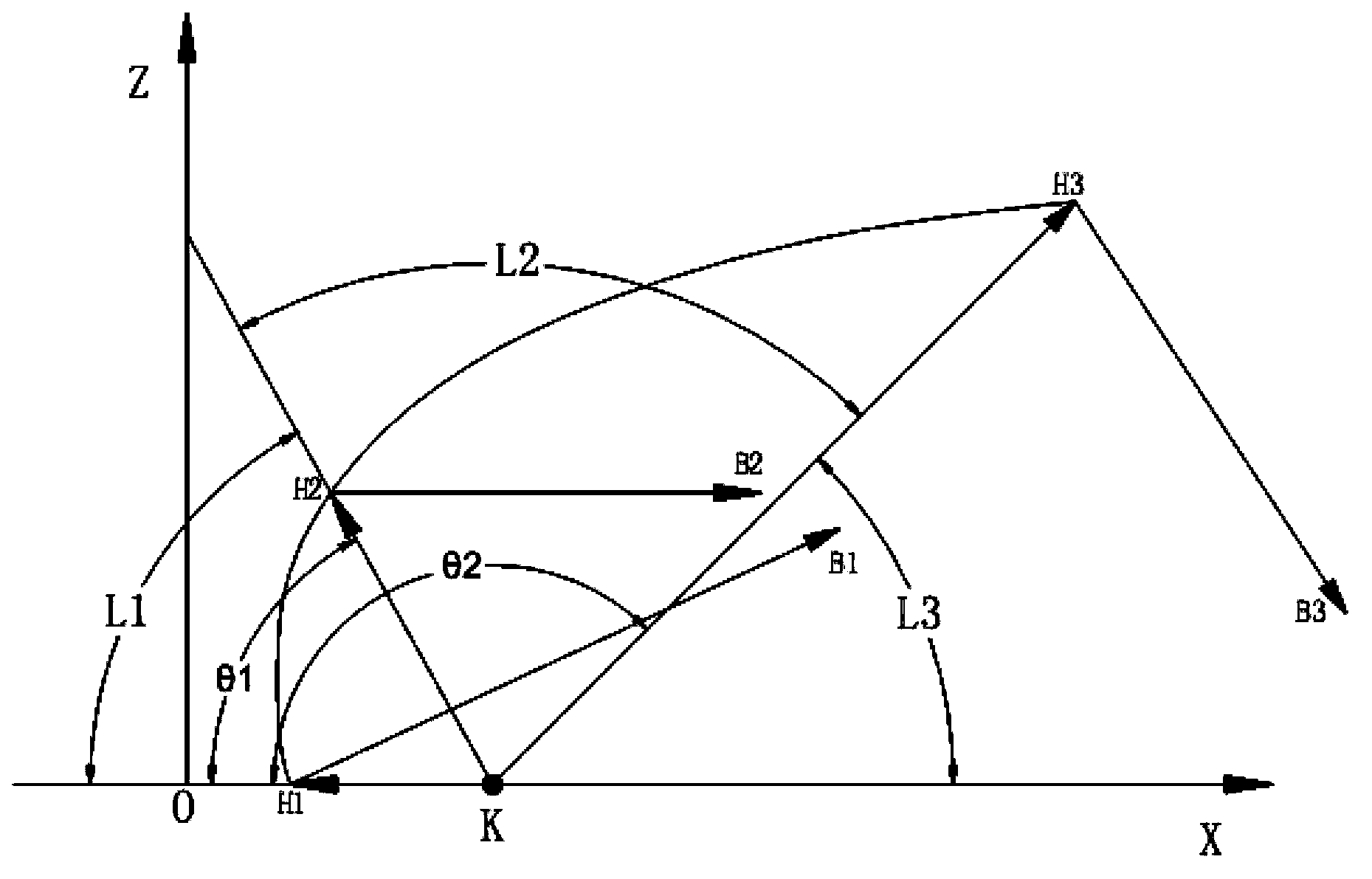

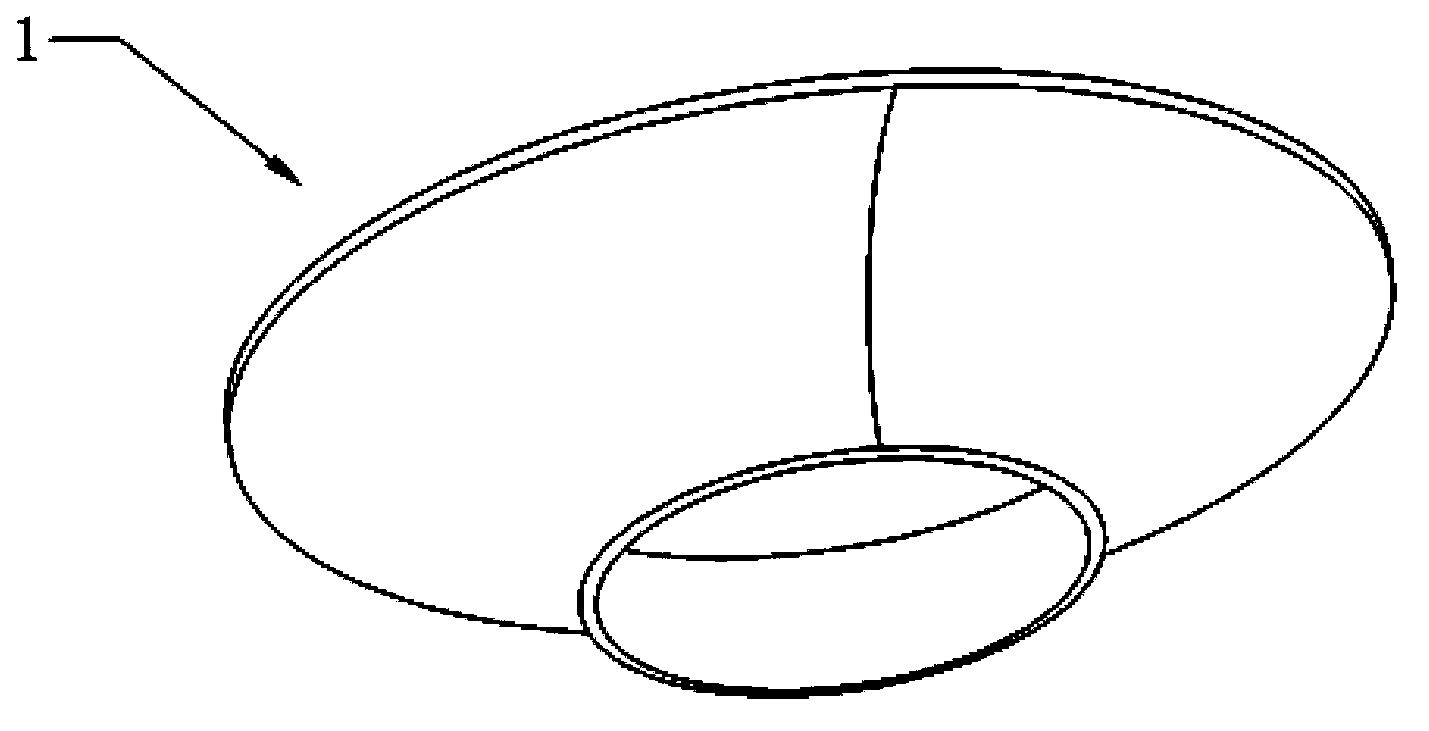

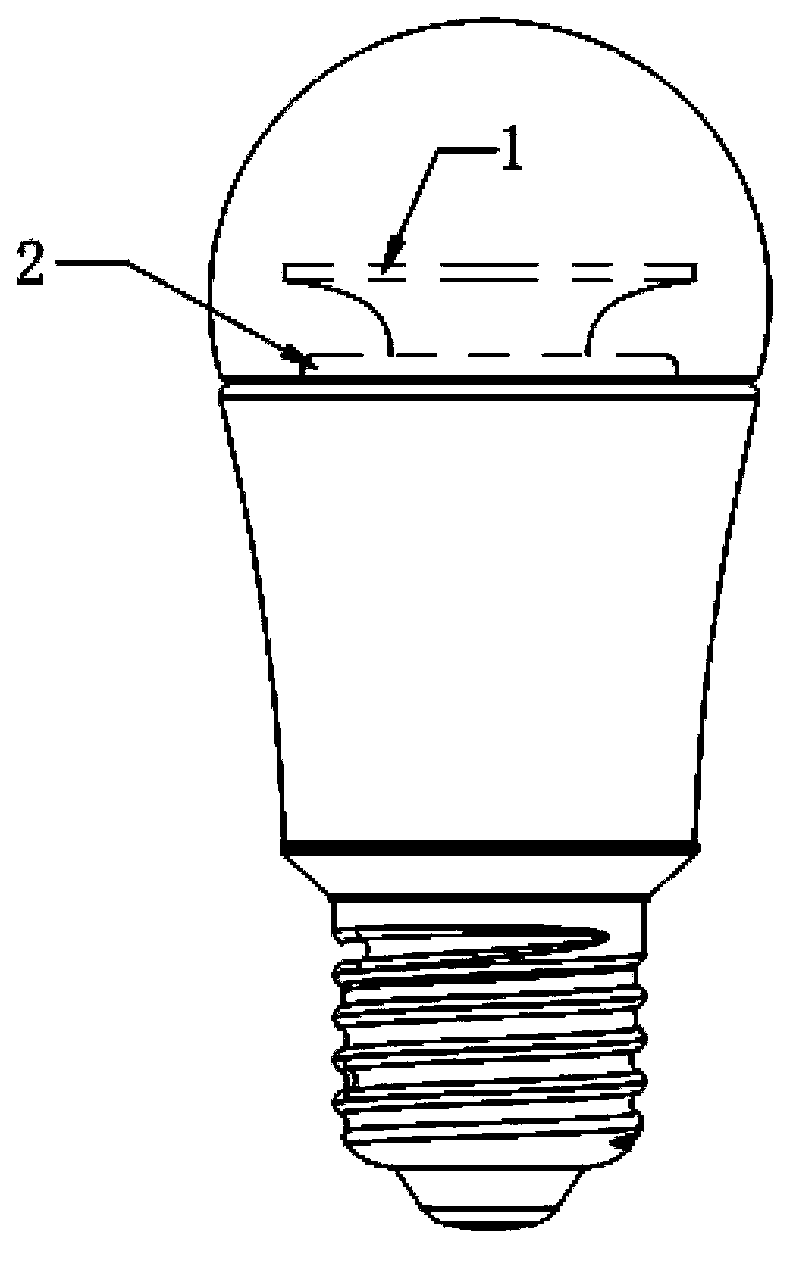

[0030] According to the above design method, in the large-angle LED bulb lamp with a luminous angle of 220 degrees, the light source adopts Samsung 2323, the number of internal light sources and external light sources are 6 and 16 respectively, and the horizontal distance between the center of the external light source and the outside of the bottom of the reflective cup It is 2.1mm. The horizontal distance between the center of the internal light source and the inner side of the bottom of the reflector is 3mm. The angles of the external single light source are 0°-70° for the reflected light in front of the lamp, 70°-135° for the reflected light behind the lamp, and direct light It is 135°-180°, the reflected light in front of the lamp and the reflected light behind the lamp correspond to the 55°-90° and 90°-135° of the target light distribution side respectively after reflection, and the direct light corresponds to the target light distribution side Corresponding to 45°-90°, th...

Embodiment 2

[0032] According to the above design method, in the large-angle LED bulb lamp with a luminous angle of 240 degrees, the light source adopts Samsung 2323, the number of internal light sources and external light sources are 8 and 16 respectively, and the horizontal distance between the center of the external light source and the outside of the bottom of the reflective cup The horizontal distance between the center of the internal light source and the inner side of the bottom of the reflector is 2mm. The angles of the external single light source are 0°-52° for the reflected light in front of the lamp, 52°-123° for the reflected light behind the lamp, and 0°-123° for the direct light. 123°-180°, the reflected light in front of the lamp and the reflected light behind the lamp correspond to the 52°-90° and 90°-135° on one side of the target light distribution respectively after reflection, and the direct light corresponds to the one-sided side of the target light distribution Corres...

Embodiment 3

[0034]According to the above design method, in the large-angle LED bulb lamp with a luminous angle of 260 degrees, the light source is Samsung 2323, the number of internal light sources and external light sources are 12 and 34 respectively, and the horizontal distance between the center of the external light source and the outside of the bottom of the reflective cup The horizontal distance between the center of the internal light source and the inner side of the bottom of the reflector is 4.2mm. The angles of the external single light source are 0°-65° for the reflected light in front of the lamp, and 65°-131° for the reflected light behind the lamp. The light is 131°-180°, the reflected light in front of the lamp and the reflected light behind the lamp correspond to the 51°-90° and 90°-135° of the target light distribution side respectively after reflection, and the direct light corresponds to the target light distribution single side Corresponding to 49°-90° on the side, divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com