Force loading method used for vehicle chassis test

A loading force and chassis technology, applied in the field of vehicle chassis performance testing, can solve problems such as inconvenient operation, large test site, and cumbersome tests, and achieve the effects of improving site utilization, saving test sites, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

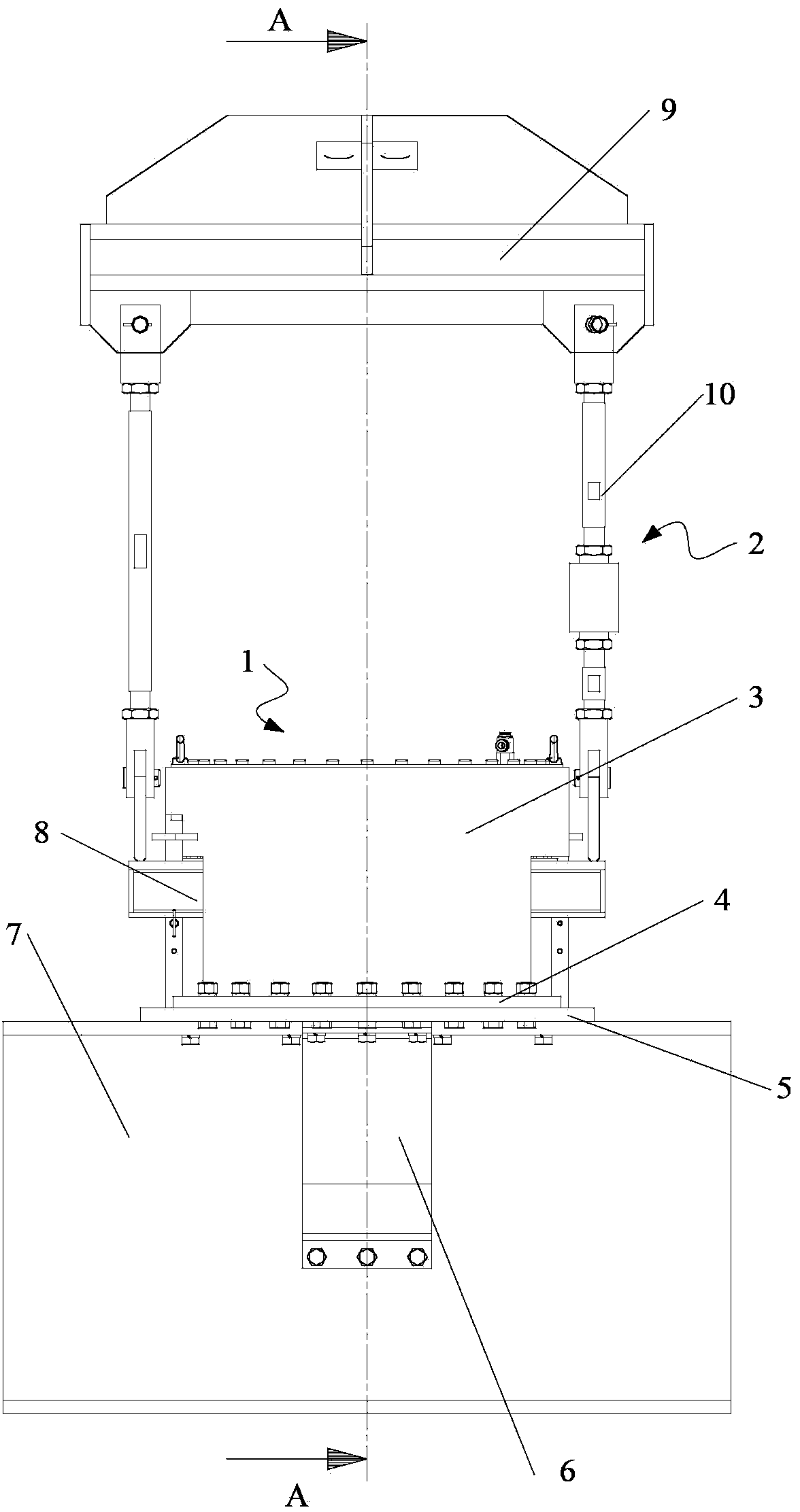

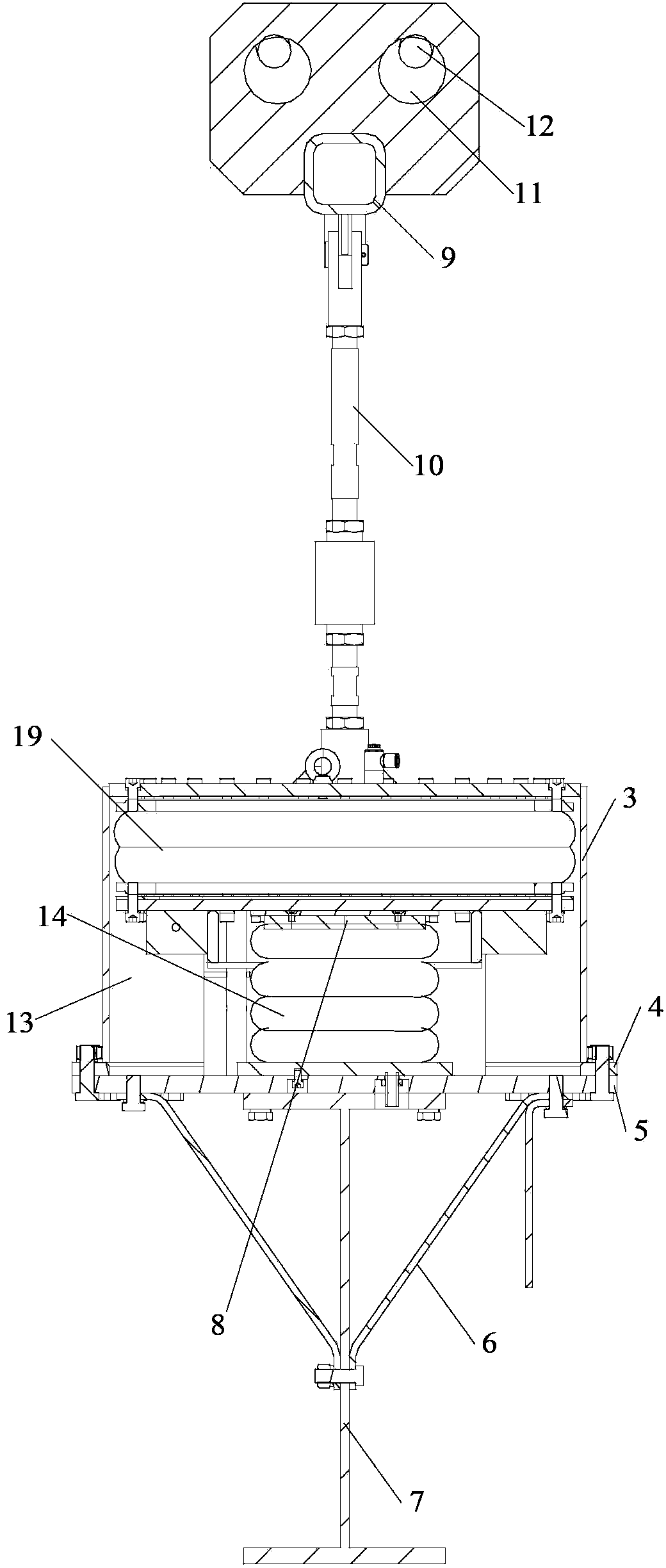

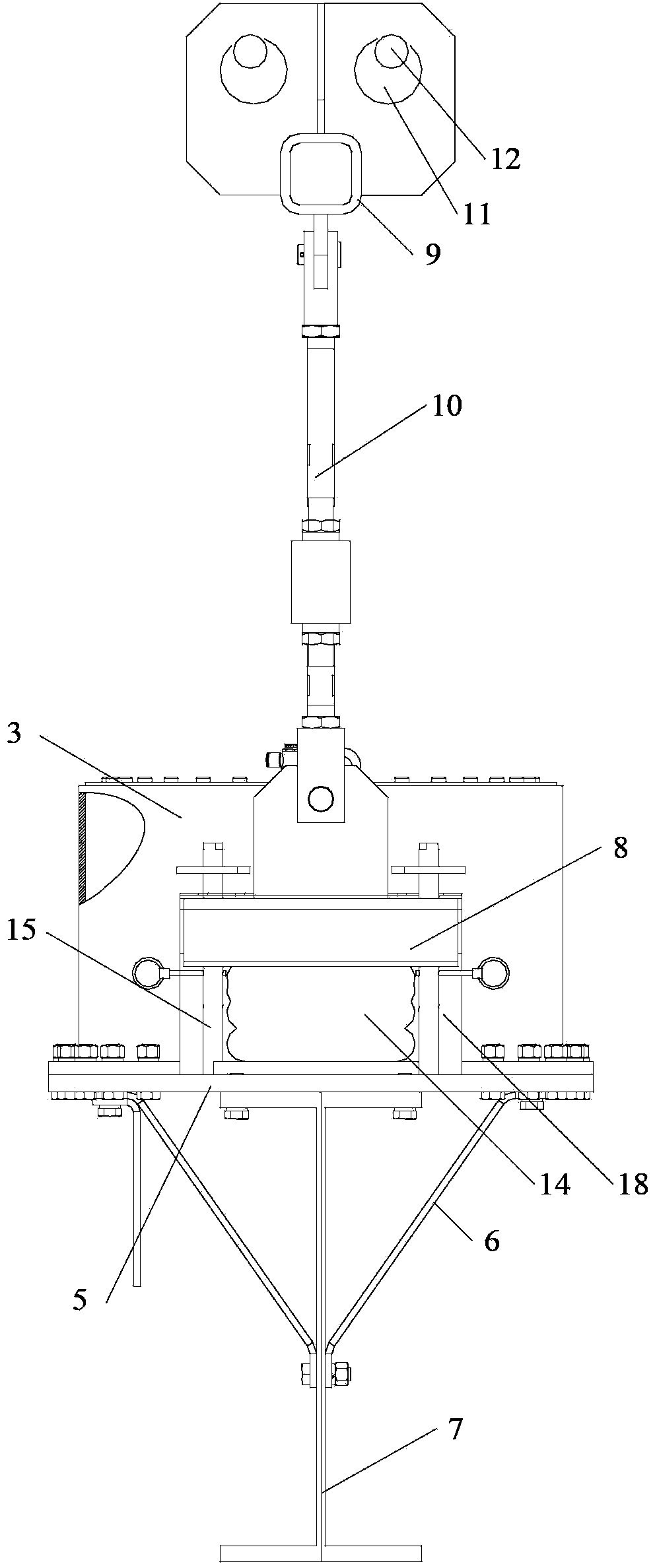

[0020] Embodiments of the present invention will be described below with reference to the drawings. Elements and features described in one drawing or one embodiment of the present invention may be combined with elements and features shown in one or more other drawings or embodiments. It should be noted that representation and description of components and processes that are not related to the present invention and known to those of ordinary skill in the art are omitted from the drawings and descriptions for the purpose of clarity.

[0021] An embodiment of the present invention provides a method of loading force for vehicle chassis testing, comprising: connecting one of the two opposite action points of the first linear drive to the force application point of the chassis to be tested, and connecting the other The application point is connected to the fixed member, and the force on the application point is correspondingly increased or reduced by controlling the extension or con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com