Apparatus for wire rope inspection, and apparatus and method for wire rope damage determination

A wire rope and inspection equipment technology, applied in elevators, material magnetic variables, elevators and other directions in buildings, can solve problems such as wear acceleration, and achieve the effect of small contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

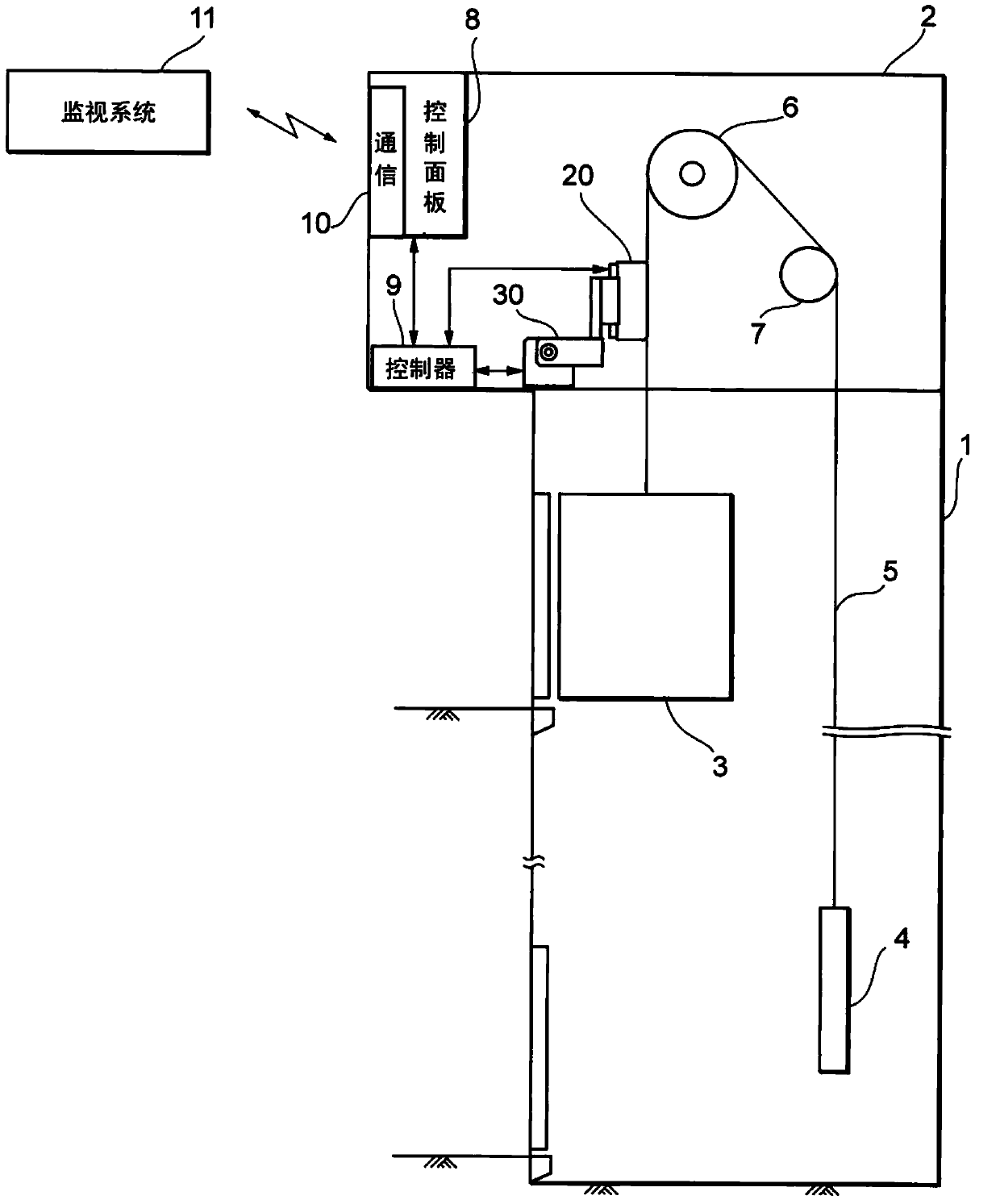

[0041] figure 1 The structure of the elevator is shown.

[0042] The elevator includes a hoistway 1, a machine room 2 provided above the hoistway 1, an elevator car 3 arranged to move up and down in the hoistway 1 to carry passengers and goods, and wire ropes 5, One end of the wire rope is fixed to the upper part (outside the roof) of the elevator car 3 and its other end is fixed to a balancer weight 4 . Usually, a plurality of wire ropes 5 arranged parallel to each other are used for the elevator. In this embodiment, four wire ropes 5 arranged in parallel are used. exist figure 1 , for clarity, only one of the wire ropes 5 is shown.

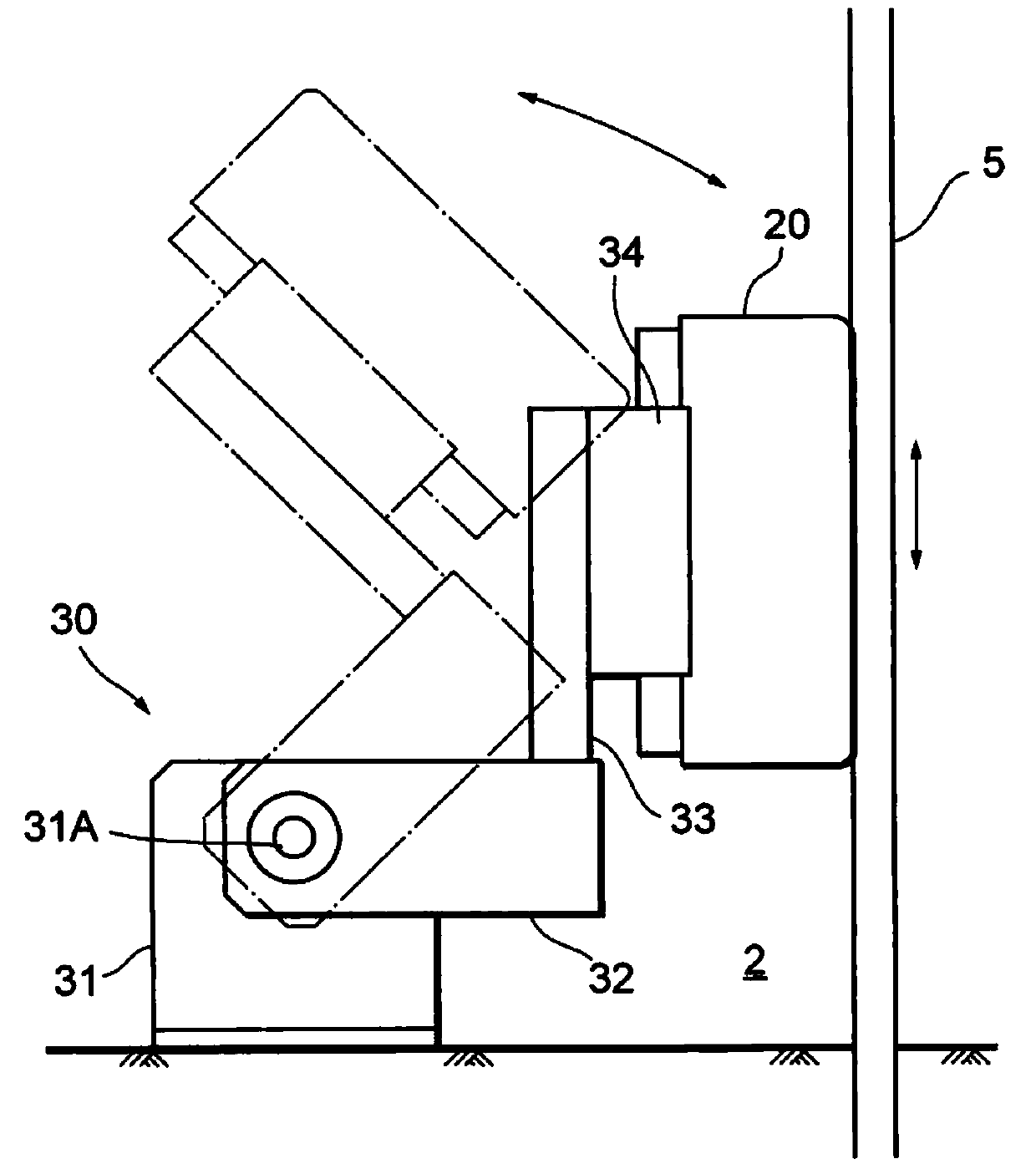

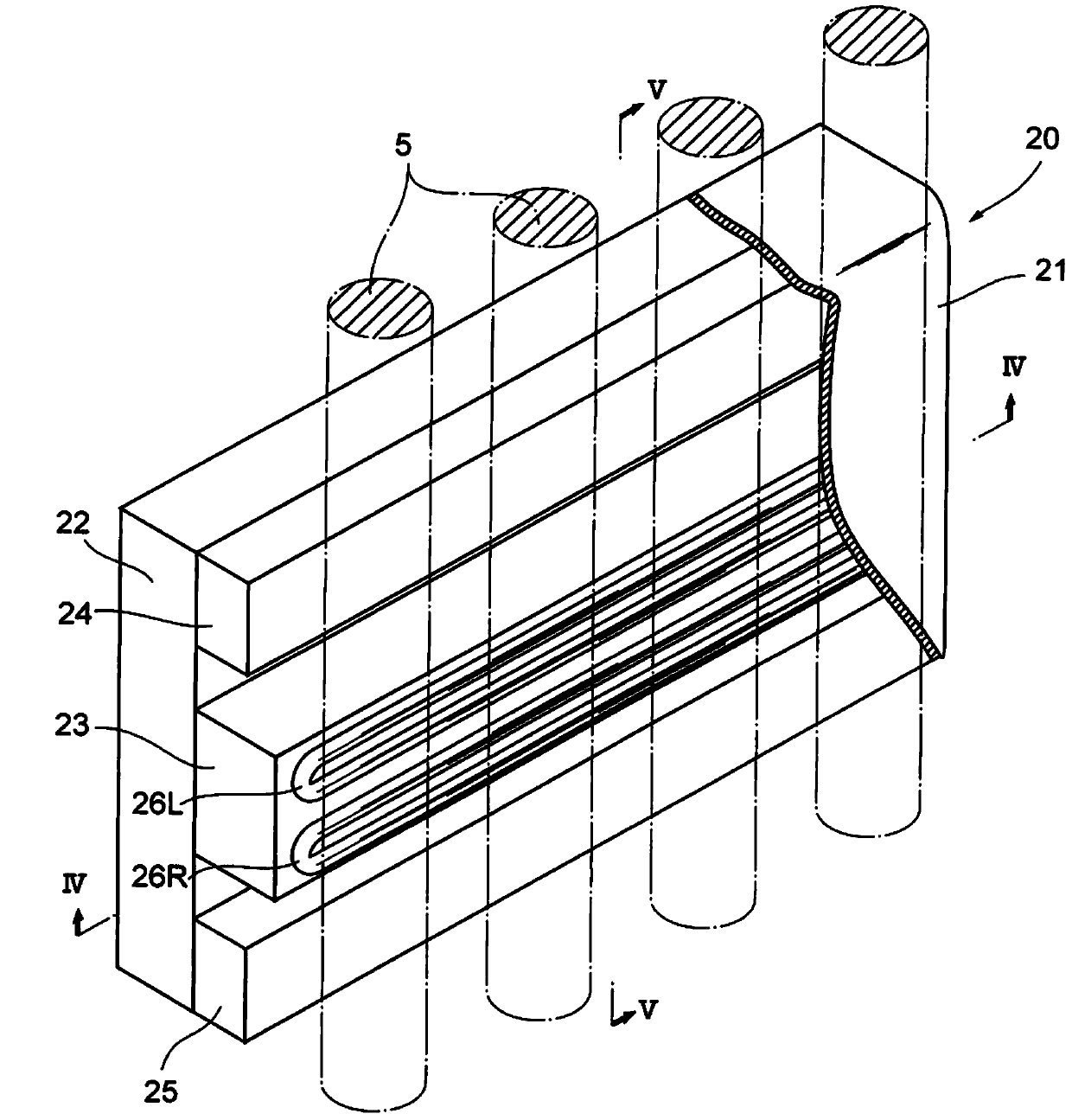

[0043] The middle part of each of the four wire ropes 5 travels (runs) through the machine room 2 , winds a hoist 6 and is applied to a deflector sheave 7 provided in the machine room 2 . An elevator control panel 8 including a communication device 10 is provided in the machine room 2 to control the hoist 6 . As the hoist 6 rotates forward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com