Touch display panel and manufacturing method thereof

A touch display panel, touch scan line technology, applied in optics, instruments, electrical and digital data processing, etc., can solve the problems of signal delay, resistance increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

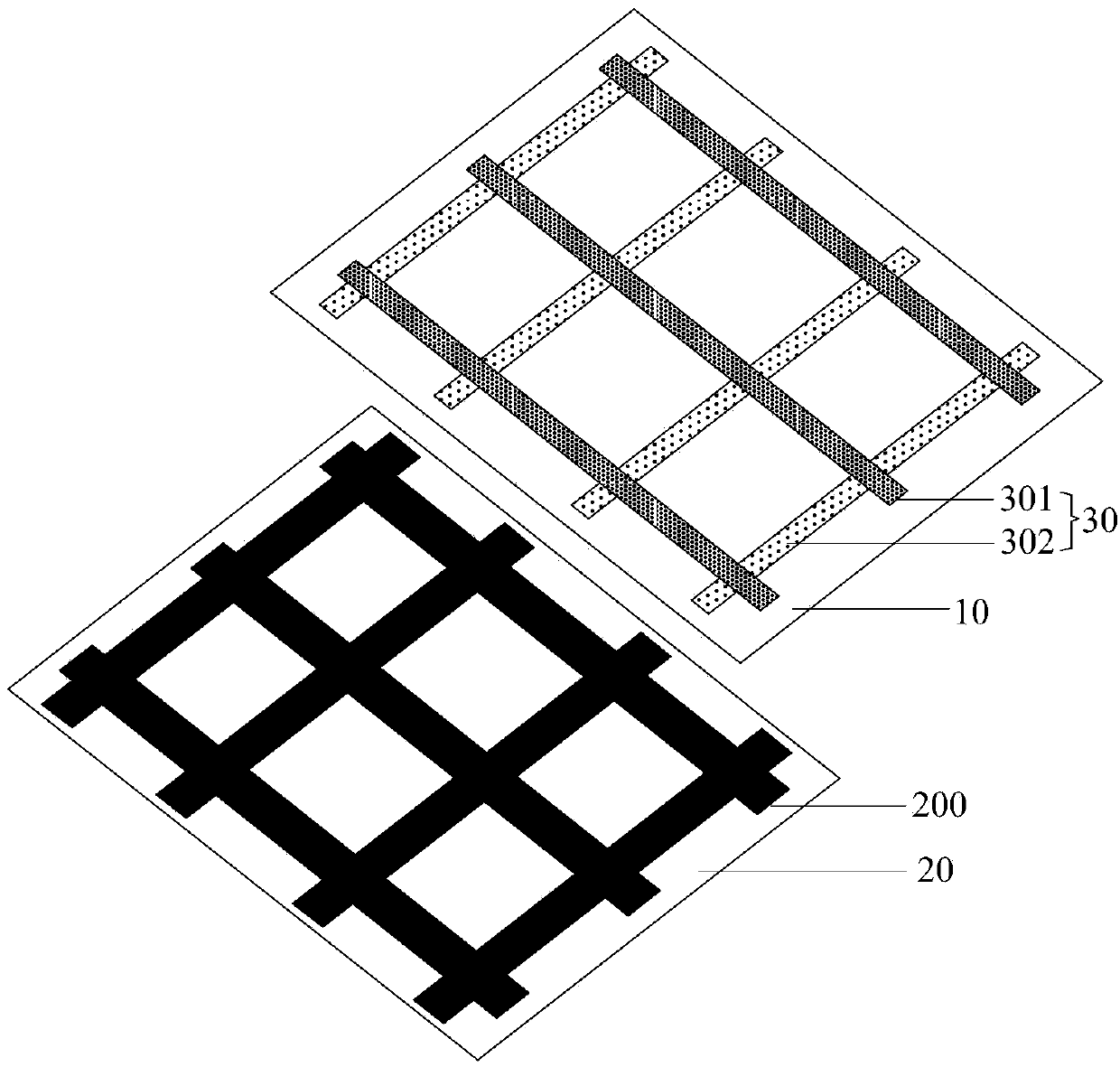

[0055] The embodiment of the present invention also provides a method for manufacturing the above touch display panel, the method includes: when forming the first electrode line 301 and / or the second electrode line 302 corresponding to the position of the black matrix 200, low temperature deposition A metal layer is formed by a process, and then a mask process is performed on the metal layer to form a metal electrode line.

[0056] Wherein, the low-temperature deposition process may be a deposition process performed by a low-temperature magnetron sputtering method; on this basis, preferably, a thickness of 100° C. can be formed by a magnetron sputtering process under an atmosphere of 20°C to 50°C. ~400nm of the metal layer.

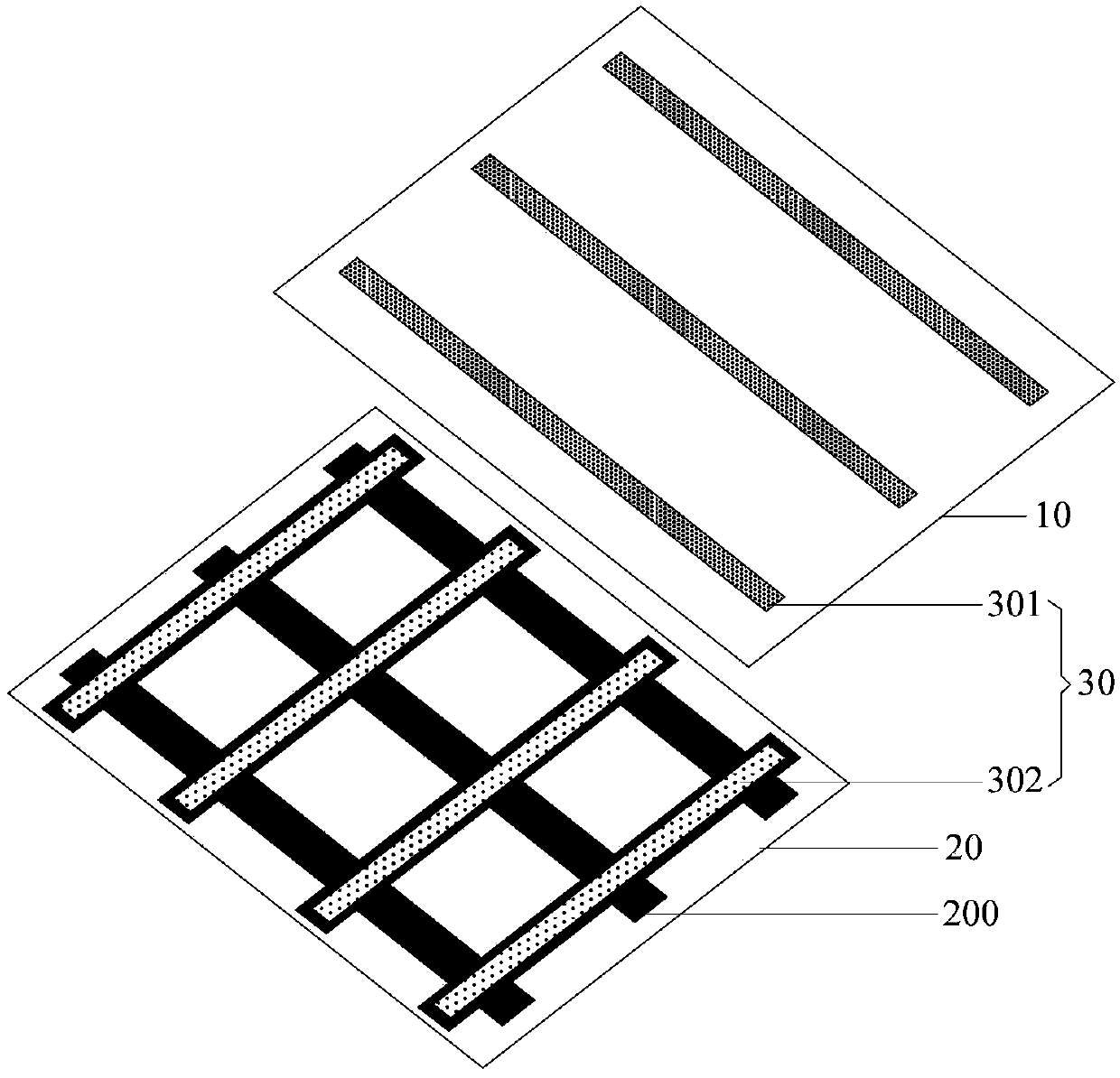

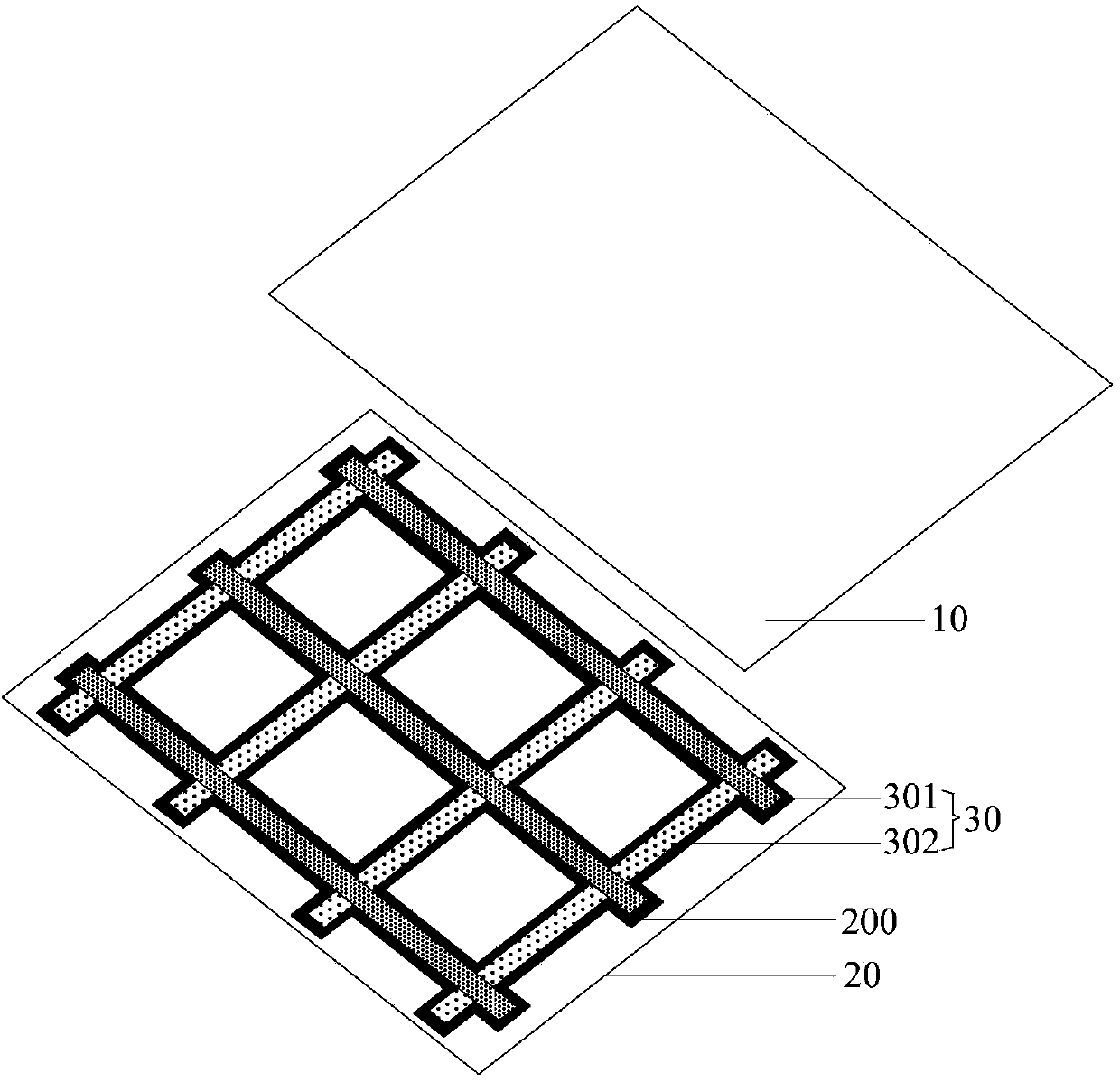

[0057] On this basis, refer to figure 2 with image 3 As shown, the first electrode lines 301 and the second electrode lines 302 may both be formed on the color filter substrate 20 or both may be formed on the array substrate 10; wherein, the first electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com