Terminal connector

A terminal connector and integrated technology, applied in the direction of multi-core cable end parts, etc., can solve the problems of large insertion force, large contact wear, instability, etc., to achieve stable and tight surface contact, large line flow capacity, The effect of small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

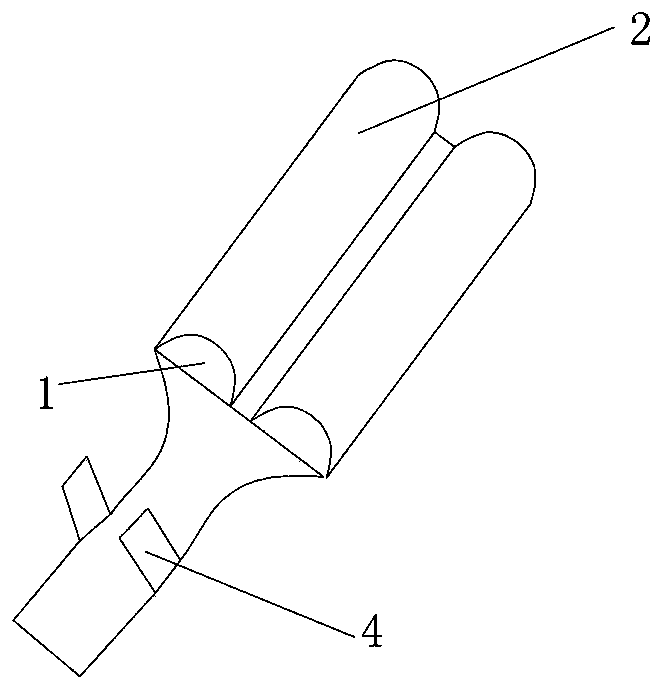

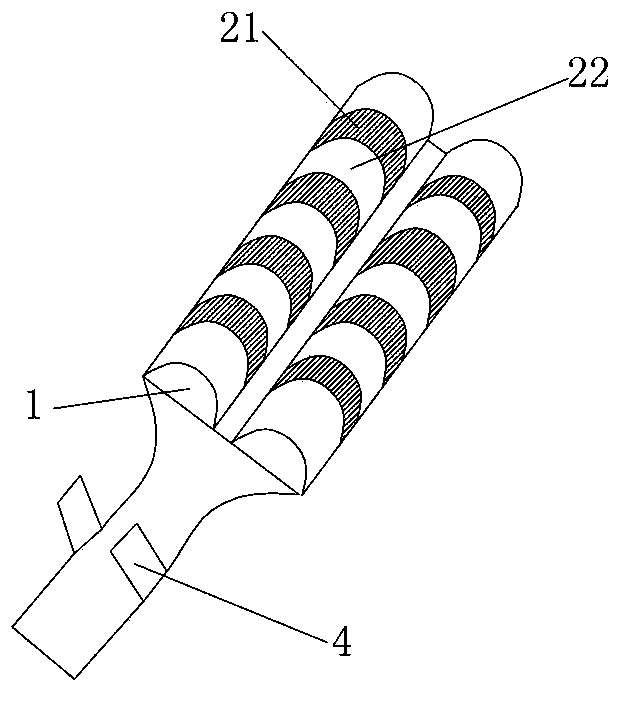

[0023] Such as figure 2 , A terminal connector, comprising a flat part 1, the lower end of the flat part 1 is connected to the terminal 4, the left and right ends of the flat part 1 are respectively bent to form a bent part 2, the bent part 2 is from the flat part 1 A plurality of mutually parallel strip-shaped bending portions 22 are respectively formed by bending the left and right ends toward each other, and the cross section of the bending portion 2 is semicircular arc shape. The number of strip-shaped bent portions 22 is two or more.

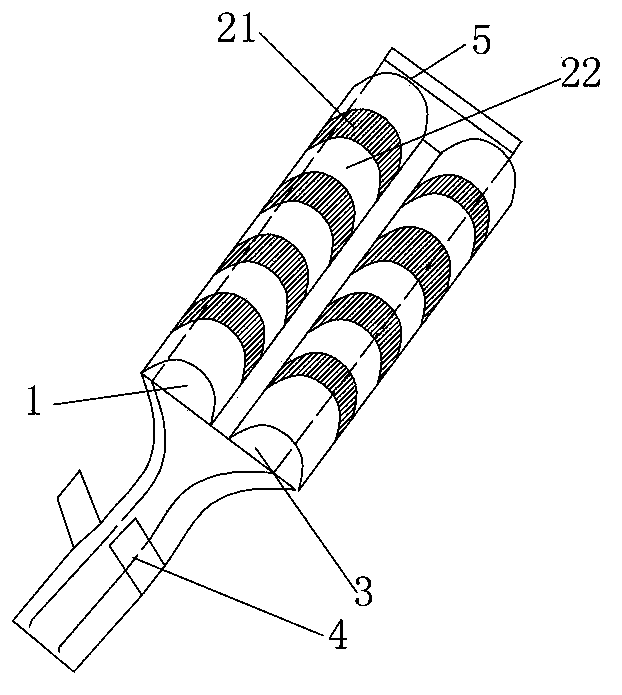

[0024] There is a gap 21 between two adjacent strip-shaped bent portions 22, or there may be no gap 21 therebetween. A corner of the free end of the bent portion 2 close to the entrance is provided with a chamfer 5 structure to facilitate plug insertion.

[0025] Such as image 3 A partition 3 is provided between the free end of the bent portion 2 and the flat portion 1, and one end of the partition 3 is fixed. Specifically, the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com