Rotor and rotating electric machine having the same

A technology of rotating electrical machines and rotors, applied in synchronous motors with stationary armatures and rotating magnets, electric components, electrical components, etc., to achieve the effects of improving rotational balance, improving magnetic properties, and increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

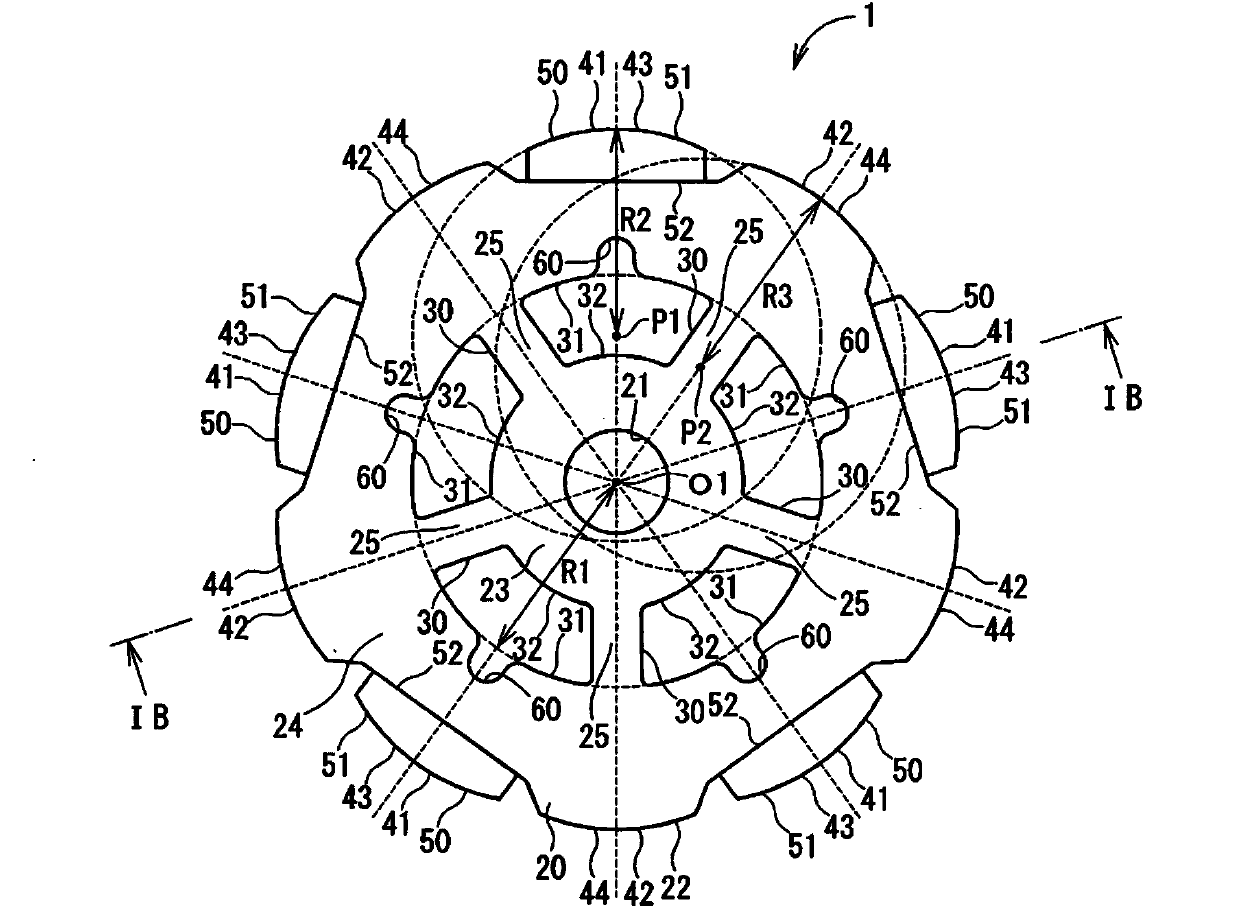

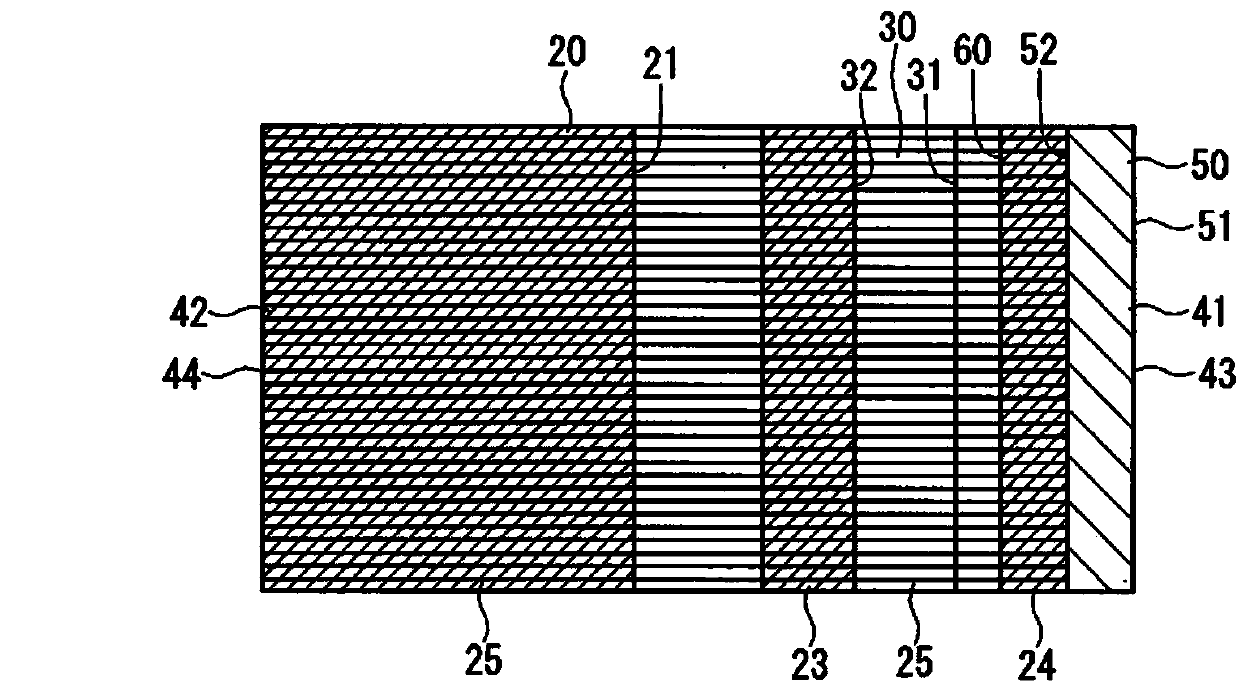

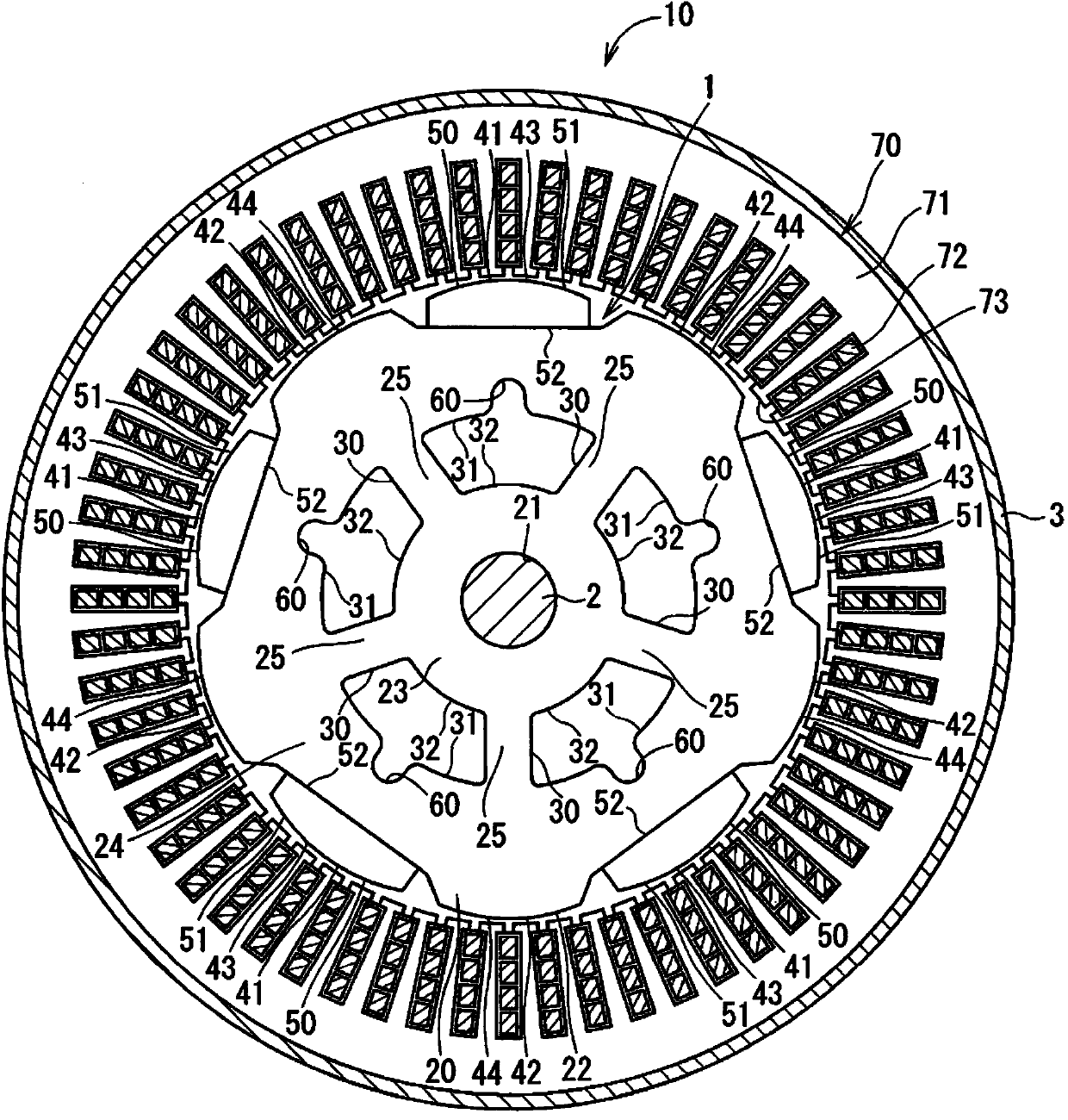

[0017] A rotor 1 according to a first embodiment is shown in Figure 1A and Figure 1B , and a rotating electrical machine 10 using this rotor 1 is shown in figure 2 middle.

[0018] The rotary electric machine 10 is used, for example, as a drive source (for example, a motor) of an electric power steering apparatus that assists a steering operation of a vehicle or the like. Such as figure 2 As shown, the rotating electric machine 10 includes a rotor 1 , a stator 70 , a motor shaft 2 and a motor housing 3 .

[0019] Such as Figure 1A and Figure 1B As shown, the rotor 1 includes a core body 20 , a through hole 30 , a first polarity portion 41 , a second polarity portion 42 and a magnet 50 . The through hole 30 may correspond to the first through hole.

[0020] The core body 20 has a substantially cylindrical shape obtained by laminating thin plates such as metal plates. The core body 20 has an axial hole 21 defined around the axis O1 and passing through the core body 2...

no. 1 approach

[0021] The through hole 30 has a generally fan-shaped cross-section and penetrates the core body 20 in the thickness direction. According to the first embodiment, the core body 20 has five through holes arranged at regular intervals in the circumferential direction of the core body 20 . The through hole 30 is one of five through holes. The through hole 30 is located between the axis O1 of the core body 20 and the outer wall 22 in the radial direction.

[0022] Furthermore, in a cross section taken along a line perpendicular to the axis O1, the through hole 30 has a substantially fan-shaped shape. The through hole 30 has an arcuate surface 31 and an arcuate surface 32 . The distance from the axis O1 to the arc surface 31 is greater than the distance from the axis O1 to the arc surface 32 . The arcuate surface 31 defines a curved wall such that the distance from the axis O1 to the point of the curved wall of the arcuate surface 31 is constant. The arcuate face 32 defines a c...

Embodiment approach

[0023] By providing the through hole 30 , the annular portion 23 is defined between the shaft hole 21 and the through hole 30 . The core body 20 has an annular portion 24 located outside the through hole 30 in the radial direction. The core body 20 also has spoke portions 25 . The spoke portions 25 and the through holes 30 are alternately arranged in the circumferential direction. The spoke portions 25 extend from the annular portion 23 to the annular portion 24 in the radial direction. According to the first embodiment, the core body 20 has five spoke portions, and the spoke portion 25 is one of the five spoke portions.

[0024] The first polar portion 41 is positioned to define the outer wall 22 of the core body 20 in the radial direction. The first polarity portions 41 and the second polarity portions 42 are alternately arranged in the circumferential direction. According to the first embodiment, the rotor 1 has five first polarity portions 41 and five second polarity p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com