Device used for plate adsorption and separation

A separation device and board technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of vacuum leakage, inability to adapt to different shapes, and inability to pick up boards, so as to improve the separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

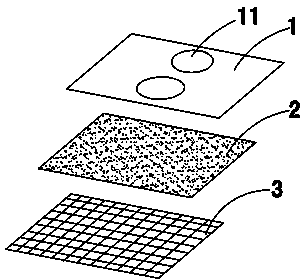

[0025] The invention discloses an adsorption and separation device for plates, which combines figure 1 As shown, it includes a metal suction plate 1 and a separating mechanism for separating the paper and the plate. Small holes are evenly distributed on the suction plate 1 . At least one suction device 11 is arranged above the suction plate 1, and the suction device may be a fan or an industrial hose. In actual application, the suction device is connected with a vacuum pump (not shown in the figure). A soft layer 2 is bonded under the suction plate 1 with glue. The soft layer 2 in the present invention refers to a material with pores evenly distributed on the surface, preferably a sponge layer. A netted anti-slip layer 3 is bonded under the soft layer 2, and the anti-slip layer 3 is a rubber layer. Of course, the soft layer 2 and the anti-slip layer 3 can also be made of other materials in addition to the above examples. The suction plate 1 can also be a ceramic suction pl...

Embodiment 2

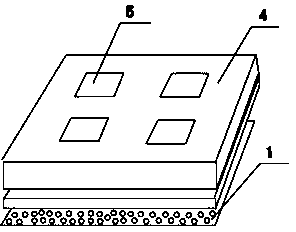

[0028] The invention discloses an adsorption and separation device for boards, which includes a porous ceramic suction board and a separation mechanism for separating paper and boards. like figure 2 As shown, the suction plate 1 is provided with a suction mechanism 4, and the suction mechanism 4 is provided with a fan 5, and the number of the fans 5 can be set as required.

Embodiment 3

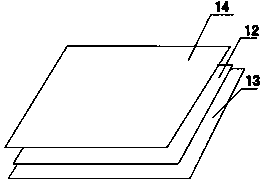

[0030] The invention discloses an adsorption and separation device for boards, which includes a suction board and a separation mechanism for separating paper and boards. like image 3 As shown, the suction plate is an electrostatic suction plate, and the electrostatic suction plate includes an upper insulating layer 11 , a lower insulating layer 13 and an electrode layer 12 disposed in the insulating layer. The electrode distribution in the electrode layer 12 is as follows Figure 4 As shown, the electrodes in the electrode layer 12 are arranged across each other. The electrostatic suction plate can be porous or non-porous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com