Heat radiating module, electronic device and dust removing method thereof

A technology for electronic devices and heat dissipation modules, which is applied to pump devices, parts of pumping devices for elastic fluids, and electrical digital data processing, etc. It can solve problems such as hindering the flow of heat dissipation airflow and affecting the heat dissipation efficiency of air-cooled heat dissipation devices. , to achieve the effect of restoring cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

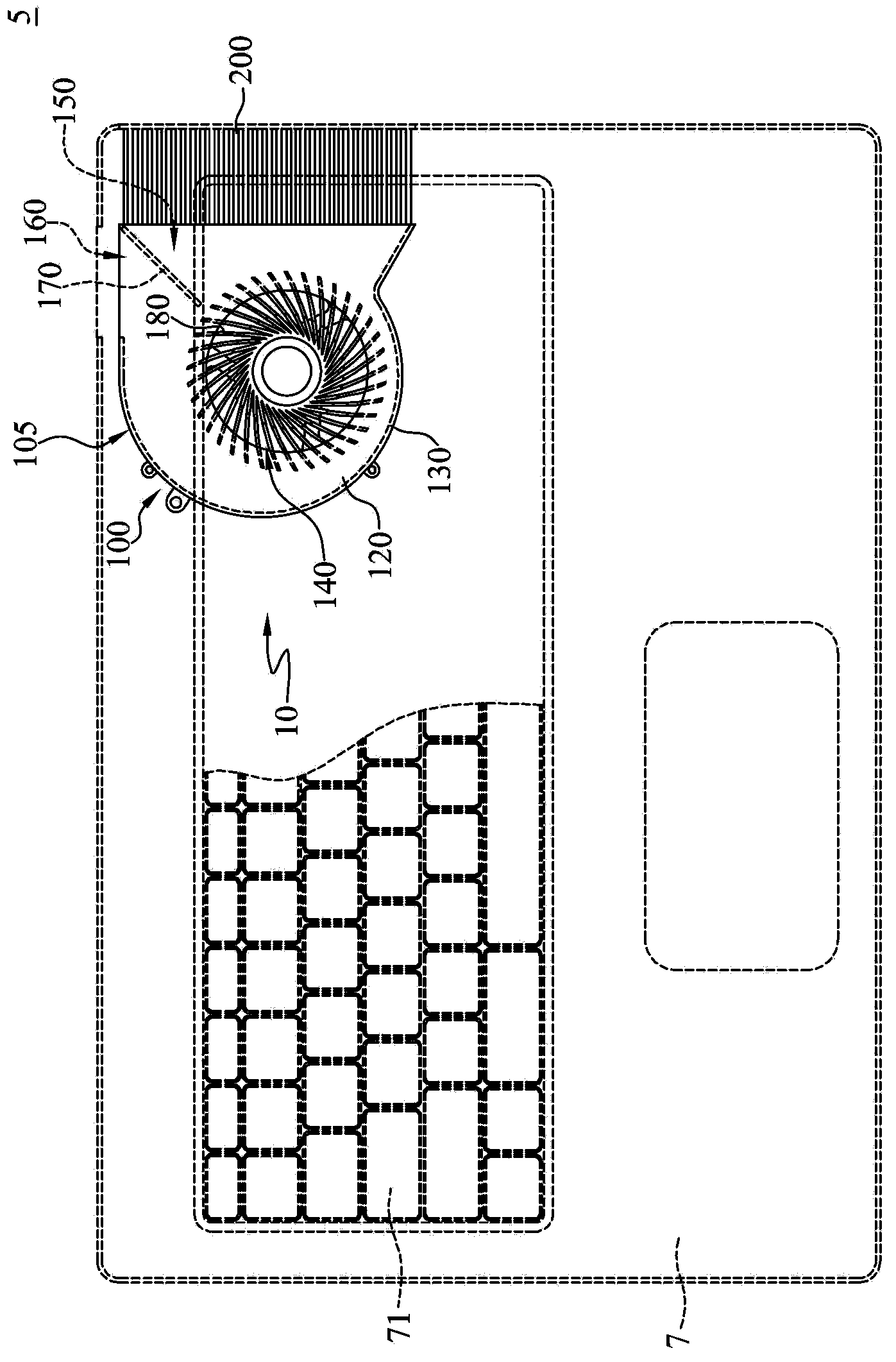

[0044] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

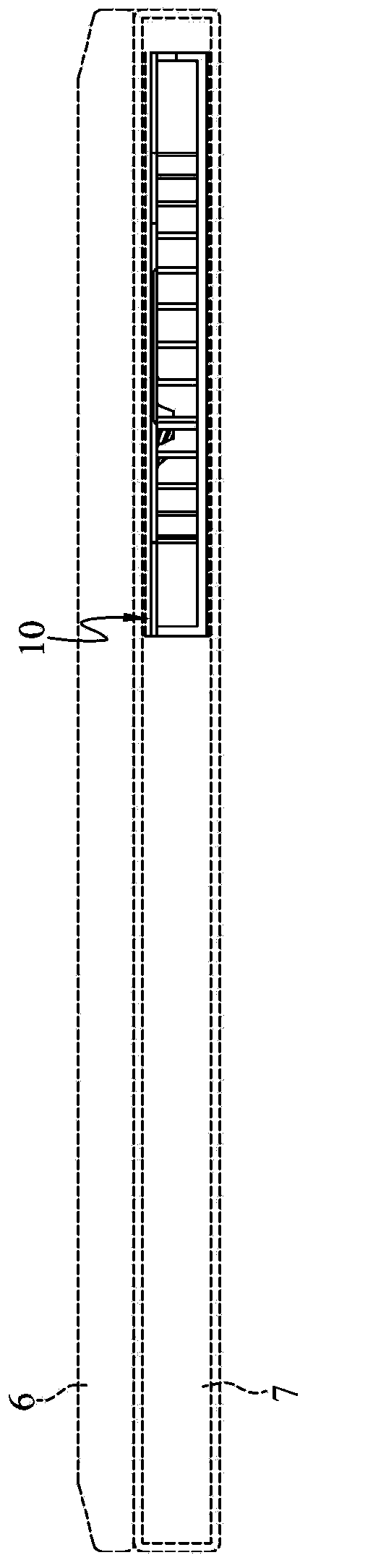

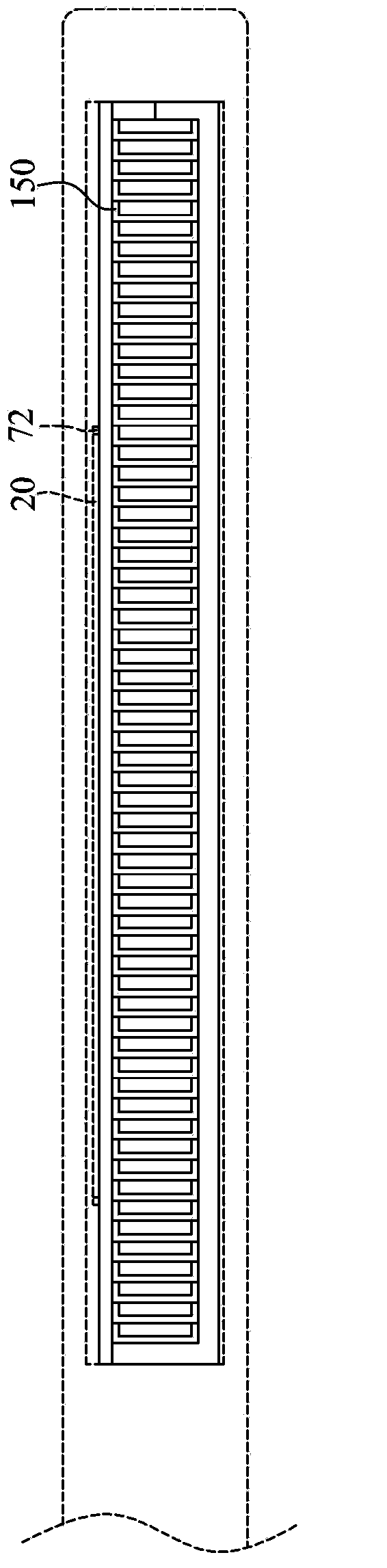

[0045] Please refer to Figure 1 to figure 2 , FIG. 1 is a schematic plan view of an electronic device according to an embodiment of the present invention, figure 2 It is a three-dimensional schematic diagram of the fan in FIG. 1 . The electronic device 5 of this embodiment is suitable for performing a heat dissipation operation or a dust collection operation, which will be described in detail as follows.

[0046] The electronic device 5 of this embodiment includes a first body 7 , a heat dissipation module 10 , a first cover 170 and a second cover 22 . The first body 7 is provided with a keyboard 71 , a socket 72 and a cooling opening 73 . The keyboard 71 faces the second body 6 . The socket 72 and the cooling opening 73 are located on the same side of the first body 7 , and the socket 72 is used for inserting the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com