Device and method for automatically selecting tobacco leaves for producing cut tobacco

A technology for making silk threads and tobacco leaves, which is applied in chemical instruments and methods, solid separation, grading, etc. It can solve the problem that the homogenization control of the purity of tobacco sheets cannot be guaranteed for long-term stability and reliability, and it is difficult to meet the requirements of fine silk-making processes. Chemical processing, time-consuming and labor-intensive problems, etc., to reduce the cost of manual leaf selection, improve the quality of cigarettes, and improve the efficiency of selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

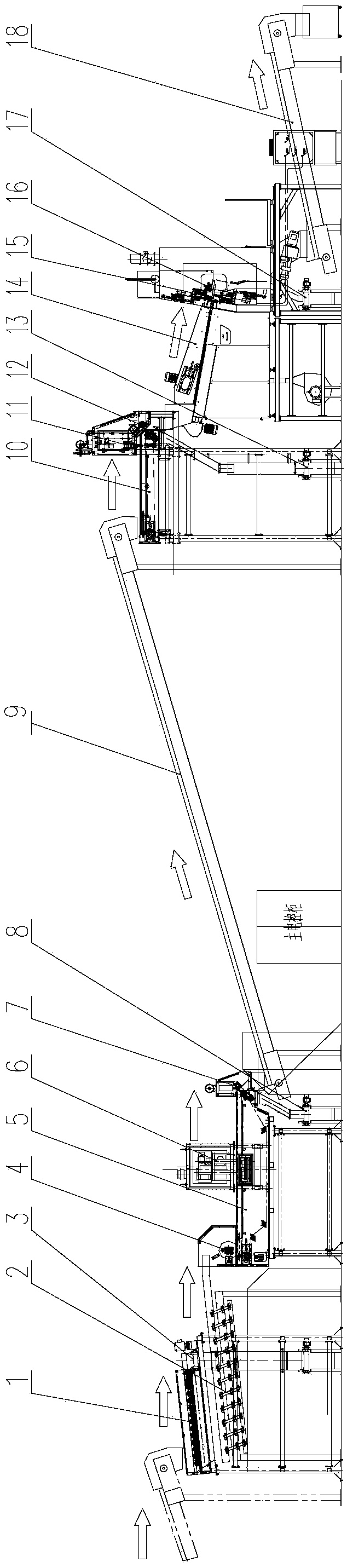

[0071] Apply device of the present invention to carry out tobacco leaf selection, and its process is as follows:

[0072] 1). The tobacco leaves flow to the star roller 1 with the tobacco leaf flow. Because the star rollers have a gap, the non-agglomerated tobacco leaves will fall to the vibrating groove 2 below, and the agglomerated tobacco blocks will stay on the star roller 1. , then flow to the agglomerated tobacco belt 3;

[0073] 2). The fallen tobacco leaves are thinned by the vibrating tank 2 and continue to flow to the thinning roller 4;

[0074] 3). Tobacco leaves continue to be thinned at the thinning roller 4, and then fall to the differential thinning belt 5;

[0075] 4).Because the speed of the differential belt is faster, the distance between the tobacco leaves is further extended. A thin layer of non-overlapping tobacco leaf flow is formed here, flowing to the tobacco stem detection device 6;

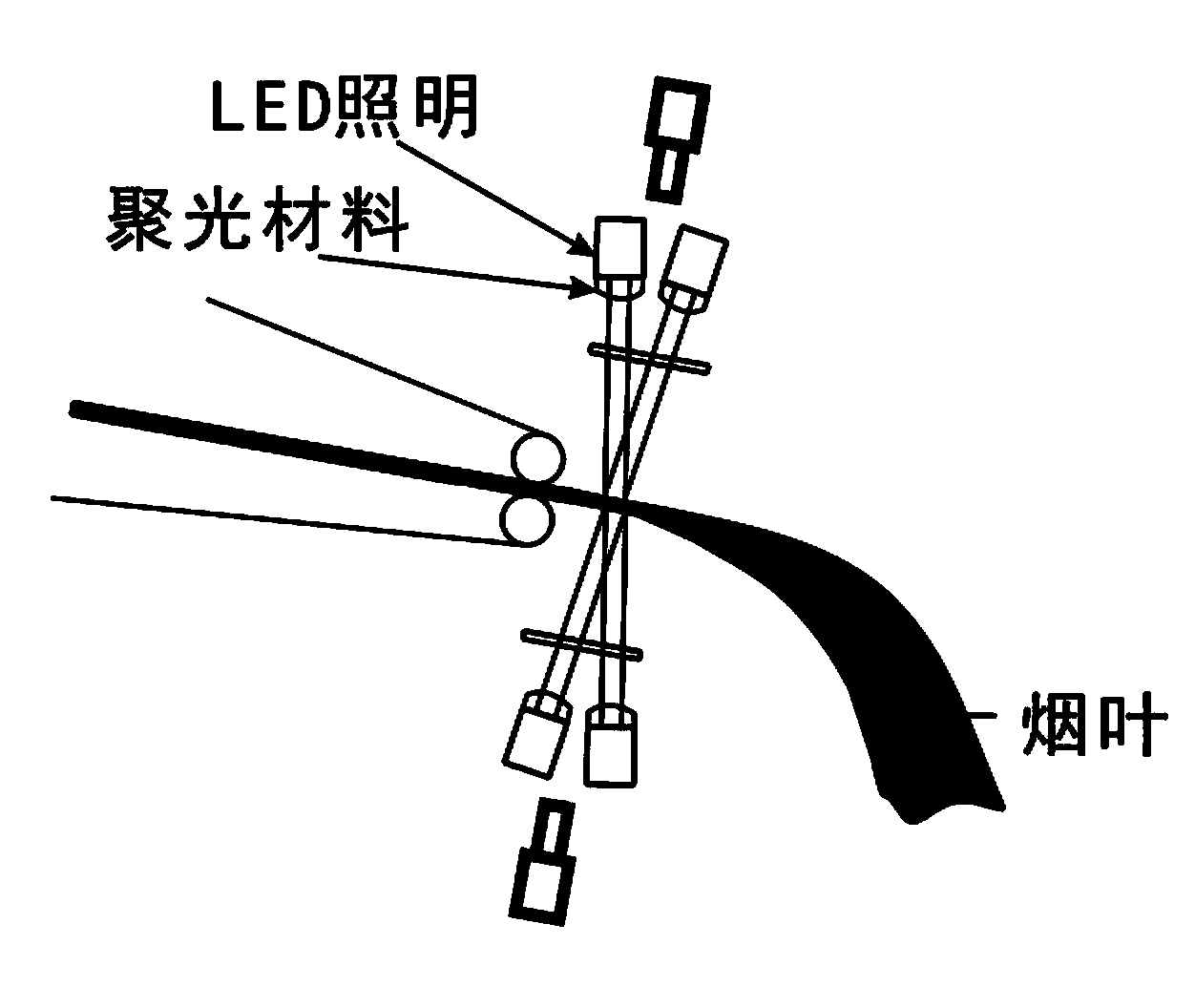

[0076] 5). At the tobacco stem detection device 6, the tobacco l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com